circular saw blade differences

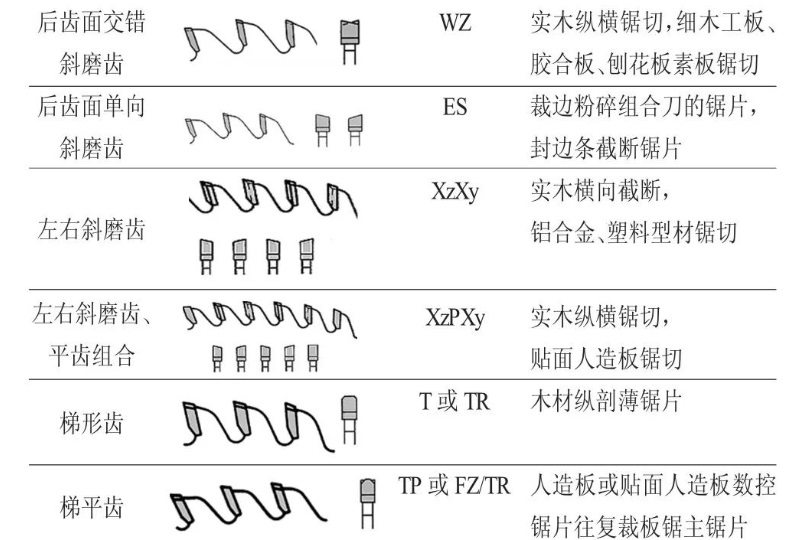

First, cutting teeth

- Ordinary tooth circular saw blade

Ordinary tooth circular saw blade is mainly used for roughing, suitable for dealing with harder wood. - T-tooth circular saw blade

T-tooth circular saw blade has a T-shaped serrate, suitable for handling softer wood. Easier to handle nails or other foreign objects than regular toothed circular saw blades. - Angle tooth circular saw blade

The tooth surface of the circular saw blade is angled, and this design can make it easier for the saw to enter the wood, which is suitable for processing wood with large grain changes. - Tipped carbide circular saw blade

The tooth surface of the tooth tip carbide circular saw blade is made of carbide material, which has higher wear resistance and is suitable for machines with higher feed speed, such as cutting multi-layer board materials.

Ii. Specifications

Step 1: Diameter

The size of the circular saw blade is based on the diameter and is generally expressed in inches (“). Large diameter circular saw blades can cut wood faster, but require more force when operating. - Number of teeth

The number of teeth of the circular saw blade determines the cutting quality. The more teeth, the better the cutting quality, but the cutting speed will slow down. Therefore, it is necessary to select the appropriate number of teeth according to the actual needs. - Cutting depth

The cutting depth of the circular saw blade refers to the depth that can be cut each time. Select the appropriate cutting depth according to the actual requirements.

In short, there are many types and specifications of circular saw blades, and choosing the right circular saw blades can improve work efficiency and quality. The above is a comparison and analysis of some common circular saw blade types and specifications, hoping to provide a reference for you when choosing circular saw blades.

Third, saw blade material

The saw blade of the circular saw is generally made of cemented carbide, which has high hardness and strength and can cut hard materials such as wood and metal with high density. The blade material of the ordinary saw is high-speed steel, carbon steel and other materials to choose from, suitable for cutting soft materials. - Use scenario

Circular saw is suitable for cutting hard materials, such as wood, metal, stone and so on. The ordinary saw is suitable for cutting soft materials, such as wood, branches, cardboard and so on. - Comparison of advantages and disadvantages

In comparison, the disc saw has high cutting efficiency and smooth cutting surface, which is suitable for mass production and processing with high quality requirements. However, its price is higher and it is only suitable for cutting hard materials. The ordinary saw has the advantages of low price and wide application range, but its cutting efficiency is low and the cutting surface is rough. - Processing efficiency

Circular saw cutting efficiency is high, and the cutting surface is smooth, suitable for mass production processing. The ordinary saw is suitable for small batch, fine processing, due to the sawing of less material each time, so its cutting efficiency is low.

【 Conclusion 】

In summary, circular saws and ordinary saws have their own advantages and disadvantages, and their application scenarios and use effects are different. In the selection of tools need to be based on the specific use requirements and material characteristics to choose.

What are the advantages and disadvantages of circular saw blade?

Advantages:

- High cutting precision: Circular saw blade adopts advanced manufacturing process, has high precision and stability, can ensure the flatness and smoothness of the cutting surface, suitable for high-precision metal processing.

- High cutting efficiency: circular saw blade has fast cutting speed and large cutting force, which can efficiently cut metal materials of various thicknesses and improve production efficiency.

- Wide range of application: circular saw blade can be applied to various types of circular saws and band saws, which is convenient for cutting metal materials of different types and sizes.

- Long service life: Circular saw blades use high-quality materials and manufacturing processes, with long service life and low maintenance costs.

Cons: - High price: Circular saw blades are relatively expensive compared to other types of saw blades, and for some small and medium-sized enterprises, the cost is high, which is not conducive to popular application.

- High operating requirements: Circular saw blades have high requirements for the operator’s skills and experience, and incorrect operation may lead to saw blade damage or a reduction in cutting quality.

- Large noise: The noise generated by the circular saw blade in the cutting process is larger, which has a certain impact on the hearing health of the staff.

- Maintenance is difficult: The maintenance and replacement of circular saw blades requires professional technicians and equipment, and for some enterprises, maintenance is more difficult.

In summary, the circular saw blade has high cutting accuracy and efficiency, but at the same time, it also has shortcomings such as high price, high operation requirements, large noise and difficult maintenance. In practical applications, the appropriate circular saw blade type and use mode should be selected according to the specific needs and actual situation to ensure cutting quality and production efficiency.Click to see more machine of grinding, packing, printing, labels industries.

Click to see more machine of grinding, packing, printing, labels industries.

Click to see more machine of grinding, packing, printing, labels industries.

We OEM your brand and also color box, printed bags, outer box packages.

You can also refer to following links if you are interest in following information:

6 color printing machine 8 side sealing bags AC EV Charger

Blender Machine

Industrial News

Industrial Information

Industrial Tech Knowledge