What is the difference between SDS and regular drill bit?

The main differences between SDS drill bits and standard drill bits lie in their connection methods and applicable scenarios.

SDS Drill Bits

SDS drill bits are specialized hammer drill bits, primarily divided into two types: SDS-Plus and SDS-Max.

- SDS-Plus: Features a two-groove, two-flute design, suitable for small to medium-sized holes and shallow drilling. Its advantage is that the bit can slide like a piston in the chuck without slipping or flying out, making it highly efficient for drilling into stone and concrete.

- SDS-Max: Features a five-groove round shank design, suitable for large and deep holes. With a shank diameter of 18mm, it provides stronger torque and a longer piston stroke, making it ideal for heavy-duty applications.

Standard Drill Bits

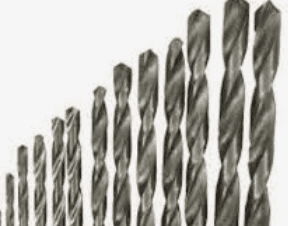

Standard drill bits typically refer to those without special connection systems, mainly divided into square-shank and round-shank types:

- Square-Shank Bits: Similar to SDS-Plus or SDS-Max, these are suitable for high-power, high-load scenarios like construction sites and engineering projects. They offer better rigidity and force transmission, allowing for quick bit changes.

- Round-Shank Bits: Designed for standard three-jaw chuck drills, these are used for general home repairs and light DIY work. While less rigid and efficient in force transmission, they are simple to operate and suitable for low-power, light-duty tasks.

Applicable Scenarios and Pros & Cons

- SDS-Plus: Best for small to medium-sized and shallow holes. Pros: Easy installation, anti-slip, efficient drilling. Cons: Limited torque, not suitable for large or deep holes.

- SDS-Max: Ideal for large and deep holes. Pros: High torque, heavy-duty performance. Cons: Higher cost, not suitable for small-diameter bits.

- Square-Shank Bits: Great for high-power, high-load tasks. Pros: Excellent rigidity and force transmission, quick bit changes. Cons: Higher cost, not ideal for light-duty work.

- Round-Shank Bits: Perfect for home repairs and light DIY. Pros: Easy operation, low cost. Cons: Poor rigidity and force transmission, unsuitable for heavy-duty tasks.

SDS Four-Groove Drill Bits

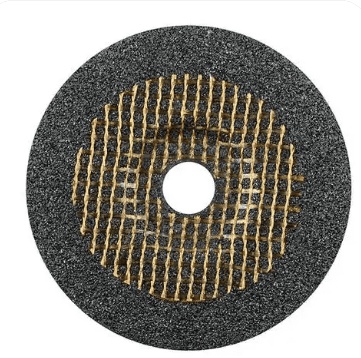

SDS four-groove drill bits are widely used in construction and renovation. The “SDS” stands for “Slotted Drive System,” featuring four grooves (four indentations) for quick insertion and release. This design ensures a more secure fit in the chuck compared to traditional clamping methods.

These bits can drill into materials like concrete, stone, brick, and ceramics. Their robust design makes them more durable than standard cutting tools. With special attachments, they can also function as chisels for tougher tasks, such as removing concrete-embedded posts or fireplaces.

Using SDS four-groove bits requires skill and experience. Despite their sturdy design, caution is necessary to avoid injury. Always check the bit and chuck for secure fastening before use, and wear safety gear like goggles, earplugs, and cooling equipment. Be mindful of potential hazards like ladders and hanging objects. Proper use ensures both safety and efficiency.

Understanding Drill Bit Model Numbers

When purchasing drill bits, you may encounter combinations like “5mm,” “HSS,” or “SDS.” These indicate the bit’s specifications:

- Diameter (mm): Indicates bit size (e.g., 5mm for a 5mm hole).

- HSS (High-Speed Steel): For drilling hard materials like metal and steel.

- SDS (Special Direct System): For hard materials like concrete and brick.

- Wood Drill Bits: Designed for wood and wooden products.

- Titanium-Coated Bits: More durable and wear-resistant.

Choosing the Right Drill Bit

Selecting the correct bit is crucial for efficiency and quality. Consider:

- Match the bit diameter to the hole size.

- Choose the bit material based on the workpiece (e.g., HSS for metal, SDS for concrete).

- Ensure the bit length matches the drilling depth.

- Select the bit type based on the hole shape (e.g., wood, masonry).

- Control drilling speed and cooling to extend bit life.

Conclusion

The numbers and letters on drill bits indicate their specifications and uses. Selecting the right bit depends on hole size, material, depth, and shape. Proper speed and cooling maintenance can prolong bit life.

Should You Choose Round-Shank or Square-Shank Hammer Drill Bits?

Background: After wearing out a hammer drill bit, I learned some key points worth sharing.

Why It Matters: A light hammer drill is essential for DIY home repairs, helping maintain your (already low) household status.

Key Insight: I once thought all hammer drill bits had the same interface. Turns out, China has two standards:

- Round-Shank: Common in light-duty domestic and Bosch hammer drills.

- Square-Shank: Developed by Chinese manufacturers to bypass Bosch’s SDS system, eventually dominating the heavy-duty market due to low cost and high demand.

Warning: There are cases of round-shank bits breaking inside square-shank hammer drills, requiring factory repairs. Beginners should research before using heavy-duty hammer drills.

Final Advice: For home repairs and light wall work, a light hammer drill with round-shank bits suffices (and is compatible across brands). For demolition or plumbing, invest in a heavy-duty hammer drill with square-shank bits—it’s more efficient and not much pricier. Always wear gloves and a mask to avoid inhaling dust.

In-Depth Analysis of Hammer Drill Shanks

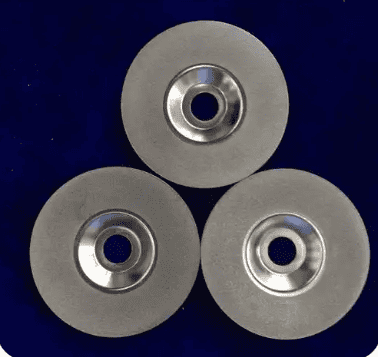

SDS-Plus (Two-Groove Round Shank)

The SDS system, developed by Bosch in 1975, evolved into SDS-Plus (or SDS+), featuring two grooves and two flutes. Its spring-loaded chuck allows the bit to slide like a piston without slipping, enhancing hammering efficiency in stone and concrete.

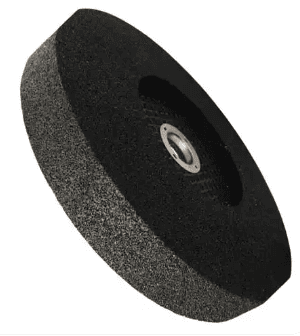

SDS-Max (Five-Groove Round Shank)

With a larger 18mm shank diameter, SDS-Max offers greater torque and piston stroke for heavy-duty drilling. It’s not a replacement for SDS-Plus but a complement for larger holes.

Four-Groove Square Shank

In China, ~90% of hammer drills use four-groove square shanks. While functionally similar to SDS-Plus, round shanks offer better concentricity and precision. Bosch dominates the light-duty round-shank market, while Chinese manufacturers lead in heavy-duty square-shank tools.

Are Square-Shank and Round-Shank Hammer Drill Bits Interchangeable?

No. Their connection interfaces differ:

- Square-Shank (SDS-Plus/Max): For high-power, high-load tasks with quick-change chucks.

- Round-Shank: For standard three-jaw chucks in light-duty drills.

Always match the bit type to your hammer drill’s chuck system for safety and performance.

Read more about electric vehicle charging station if you are interested.