Can HSS drill bits be used for concrete?

Although HSS drill bits possess high hardness and wear resistance, they are not suitable for drilling concrete. Concrete is a hard material composed of a mixture of cement, sand, stone, and other materials, containing numerous hard particles and air pockets internally. During the drilling process, these hard particles generate significant friction against the drill bit, leading to rapid wear or even breakage. Additionally, the high hardness and non-uniformity of concrete make the drilling process exceptionally challenging.

Therefore, for drilling concrete, it is recommended to use specialized concrete drill bits or tools such as hammer drills. These tools are designed with unique cutting structures and materials to better adapt to the characteristics and requirements of concrete drilling.

HSS is the industrial term for high-speed steel.

Titanium-coated HSS drill bit: A high-speed steel drill bit treated with titanium coating.

Drilling is essentially a cutting process, and the prerequisite for successful cutting is that the hardness of the tool material must exceed that of the workpiece.

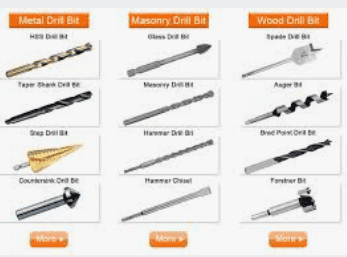

For drilling wood, wood drill bits are used. These bits are designed for high material removal rates and do not require extremely high hardness; they are typically made of standard high-speed steel (HSS).

For drilling general metal materials (alloy steel, non-alloy steel, cast iron, cast steel, non-ferrous metals), metal drill bits are employed, usually made of high-speed steel (with premium variants containing cobalt, HSS-Co).

For drilling concrete and stone materials, hammer drills with masonry bits are used, featuring carbide tips.

For harder materials like tiles and glass, tile drill bits made of tungsten carbide are recommended. Due to their high hardness and lower toughness, these bits must be used at low speeds and without impact.

In material processing, selecting the appropriate drill bit hardness is crucial, as it directly impacts efficiency and cost.

- For medium- to low-hardness metals (e.g., iron, copper, aluminum, stainless steel), HSS drill bits are recommended. They offer balanced hardness, high cutting efficiency, and cost-effectiveness.

- For high-hardness materials (e.g., glass, tiles, cement, ceramics), carbide drill bits are preferable due to their superior hardness, toughness, and wear resistance, enhancing efficiency and lifespan.

- For extremely hard materials (e.g., rock, concrete, ore) and specialized applications (e.g., oil exploration, mining), PDC (polycrystalline diamond compact) drill bits are indispensable, offering ultra-high hardness, longevity, and cutting performance.

In summary, selecting the right drill bit based on material hardness is key to optimizing efficiency and reducing costs.

C. Classification by Application

Another common method of categorizing drill bits is by their specific applications, which helps in understanding their unique features and suitable use cases.

- Center Drill Bits: Primarily used for pre-drilling positioning, available with 60°, 75°, or 90° tip angles.

- Twist Drill Bits: Widely used in industrial manufacturing for drilling various materials.

- Carbide Drill Bits: Feature carbide tips or full-body carbide construction for machining hard materials.

- Oil Hole Drill Bits: Equipped with small holes along the shaft to deliver cutting fluid to the cutting edge, reducing heat and clearing chips.

- Deep Hole Drill Bits: Originally designed for gun barrels and stone drilling, featuring straight flutes for efficient chip evacuation.

- Drill Reamers: Combine drilling and reaming functions, with a drill bit at the front and a reamer at the rear for precision machining.

- Taper Drill Bits: Designed for machining mold feed ports with tapered profiles.

- Counterbore Drill Bits: Also known as spot-facing cutters, featuring a smaller pilot diameter for counterboring.

- Countersink Drill Bits: Used for drilling conical holes, available in 90° or 60° angles (e.g., chamfering tools).

- Triangular Shank Drill Bits: Designed for power drills, with triangular shanks for secure chuck gripping.

When selecting drill bit materials, the hardness relationship between the tool and workpiece must be considered. Generally, the drill bit hardness should be at least three times that of the workpiece to ensure effectiveness and durability. Common materials include HSS, cobalt HSS, powdered HSS, and tungsten carbide, each offering progressively higher hardness for different needs.

Guide to Drill Bit Applications and Material Selection

The essence of drill bits lies in the “hardness rule”: the tool material must surpass the workpiece! From HSS to tungsten carbide, the evolution of materials mirrors humanity’s conquest of metals. Center drills ensure precision positioning, oil hole bits enable intelligent cooling, and triangular shank bits provide firm grip—every micron of tolerance holds the code of industrial civilization. Choosing a drill bit is like selecting combat gear: wood bits dominate fibers, masonry bits tackle concrete, and a 0.05mm edge tolerance can determine victory.

Overview of Drill Bits

A drill bit is a rotating cutting tool essential for creating holes in metal or other materials. Common materials include carbon steel (SK) or high-speed steel (SKH2, SKH3), manufactured through milling, rolling, heat treatment, and precision grinding. Drill bits are widely used in drill presses, lathes, milling machines, and handheld drills.

Classification by Structure:

- Solid Drill Bits: The tip, body, and shank are made from a single continuous material.

- Tip-Welded Drill Bits: The cutting tip is welded with carbide for enhanced performance.

Classification by Shank:

- Straight Shank Drill Bits: Typically for diameters ≤ φ13.0mm.

- Taper Shank Drill Bits: Feature a tapered shank, often following Morse taper standards.

Material Selection Based on Workpiece

- Wood: Wood drill bits with standard HSS suffice due to lower hardness requirements.

- Metals: Metal drill bits made of HSS or cobalt HSS.

- Concrete/Stone: Masonry bits with carbide tips, used with hammer drills.

- Tiles/Glass: Tungsten carbide tile bits, requiring low-speed, non-impact operation.

Core Functions of Drill Bits

Drill bits create through-holes or blind holes and can enlarge existing holes. Common types include twist drills, flat drills, center drills, deep hole drills, and trepanning drills. While reamers and countersinks don’t drill, they are often grouped with drill bits. Selection depends on material hardness, hole requirements, and bit specifications.

Drill Bit Specifications

Key parameters include minor diameter, major diameter, overall length, flute length, and shank diameter, all critical for accuracy and efficiency. Tolerances (e.g., edge diameter tolerance of -0.05) ensure consistency and precision.

Advanced Drill Bit Technologies

- HSS Cobalt Twist Drills (e.g., Raxwell M35): Excel in stainless steel, mold steel, cast iron, and aluminum. Cobalt enhances heat and wear resistance.

- Unsuitable Materials: Avoid using HSS bits for tiles, concrete, or stone.

Grinding and Usage Tips

- Maintain a 60° point angle for optimal cutting edges.

- Higher length-to-diameter ratios increase bending risk, leading to breakage or inaccuracies.

Hammer Drill Bits

Ideal for concrete and brick, hammer drill bits feature alloy steel bodies and carbide tips. Available in round or square shanks, with sizes ranging from 6mm to 28mm (e.g., 350mm length for wall penetration).

Final Notes

From 1.04.036 to -0.05, every micron reflects relentless craftsmanship. Whether it’s 1.85.0200 or 2.46.0150, each iteration pushes the boundaries of drill bit technology, delivering unparalleled performance for diverse applications.

(Note: Some repetitive or fragmented numerical data in the original text has been

Read more about slow charging for ev if you are interested.