Can you use an SDs bit in a normal drill?

Can Regular Drills Use SDS Drill Bits?

Regular drills can use SDS (Slotted Drive System) drill bits, but only under specific conditions. SDS bits typically refer to PDC (Polycrystalline Diamond Compact) bits, which are designed for hard and abrasive formations, offering high cutting efficiency and long service life. However, using SDS bits with a regular drill requires attention to the following:

- Power & Torque Requirements

- SDS bits require high rotational torque and power to operate effectively.

- If the regular drill lacks sufficient power/torque, it may fail to drive the bit properly or even damage the drill or bit.

- Always check if your drill meets the minimum torque and power requirements before using an SDS bit.

- Formation Suitability

- SDS bits excel in hard rock and abrasive formations.

- If drilling soft or medium formations, SDS bits may not be cost-effective, as their high-performance cutting won’t be fully utilized.

- Operator Skill & Maintenance

- SDS bits require proper handling and maintenance.

- Inexperienced users may reduce bit lifespan or cause poor drilling performance.

- Ensure operators are trained in SDS bit usage for optimal results.

Are Drill Bit Models Interchangeable? Can Any Bit Fit Any Drill?

No, not all drill bits are universally compatible. Different bit models are designed for specific drills.

1. Common Drill Bit Types & Compatibility

| Bit Type | Compatible Drills | Key Features |

|---|---|---|

| Straight Shank | Standard hand drills | 6mm diameter, basic grip |

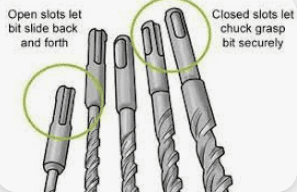

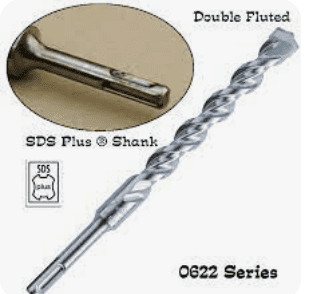

| SDS (SDS-Plus/SDS-Max) | SDS hammer drills | Grooved shank, impact-ready |

| Square Shank | Hammer drills | Small diameter (<10mm), heavy-duty |

| Hex Shank | Impact drills, rotary hammers | Anti-slip, high torque |

2. Why Bits Aren’t Universal?

- Different Chuck Systems:

- SDS bits won’t fit a standard drill chuck.

- Hex shank bits require an impact drill.

- Brand Variations:

- Even within the same type (e.g., SDS-Plus), some brands may not fit perfectly.

- For best results, match the bit brand with your drill.

3. Safety & Usage Tips

✔ Check wear – Worn bits can break mid-use, causing injury.

✔ Avoid hard materials – Using the wrong bit on stone/metal reduces lifespan.

✔ Adjust speed/torque – Prevents jamming or overheating.

Final Verdict:

- Bits are NOT universally compatible.

- Always match the bit type to your drill’s chuck system (SDS, hex, straight shank, etc.).

Which Drill Bits CANNOT Be Used in a Hammer Drill?

1. Hammer Drill Basics

- A hammer drill combines rotation + hammering action for masonry/concrete.

- Requires specialized bits (SDS/SDS-Plus/SDS-Max) for impact resistance.

2. Bits That DON’T Work in Hammer Drills

❌ Standard Round Shank Bits – No locking mechanism, will slip or break.

❌ Large Flute/Tooth Bits – Cause excessive vibration, damaging the drill.

❌ Wood/Metal Bits – Not designed for hammering, will dull or snap.

3. Why These Bits Fail?

- No SDS Locking: Standard bits lack grooves for hammer drill chucks.

- Vibration Damage: Non-SDS bits transfer shock poorly, wearing out the drill.

- Safety Risk: Bits can fly out at high speed under hammer force.

4. Only Use These in Hammer Drills:

✅ SDS-Plus (most common)

✅ SDS-Max (heavy-duty demolition)

✅ Specialty Masonry Bits (carbide-tipped)

Conclusion:

- Never use standard round-shank bits in a hammer drill.

- SDS bits are mandatory for safe, efficient hammer drilling.

How to Choose the Right Drill for SDS Bits?

1. Machine Requirements

🔧 Power: ≥1500W for hard rock drilling.

⚡ Torque: ≥50Nm for efficient SDS bit performance.

🔨 Impact Rate: ≥4000 BPM (for concrete/rock).

2. Formation Compatibility

| Material | Best Drill Type |

|---|---|

| Hard Rock | Hydraulic Drill (high torque) |

| Concrete | Heavy Hammer Drill (3J+ impact) |

| Medium Rock | High-Power Rotary Hammer |

3. Critical Checks Before Use

✔ Shank Compatibility (SDS-Plus vs. SDS-Max)

✔ Cooling System (water-assisted for deep drilling)

✔ Operator Control (variable speed, anti-vibration handle)

Final Tip:

- For long-term heavy drilling, invest in a hydraulic drill.

- For DIY/concrete work, a high-end hammer drill suffices.

- Always prioritize SDS bit compatibility for safety and efficiency.

Summary of Key Points

✅ SDS bits work in regular drills ONLY if power/torque are sufficient.

❌ Drill bits are NOT universal – match shank type to your drill.

⚠️ Never use standard bits in hammer drills – SDS is mandatory.

🔧 Choose high-torque, impact-ready drills for SDS bit efficiency.

By following these guidelines, you’ll maximize drilling performance and tool lifespan while ensuring safety. 🚀

Read more about drills packing method if you are interest.