Are grinding wheels safe?

ls are used improperly, they can be extremely dangerous. Appropriate protective measures must be taken, and safety training must be conducted before use.

Recently, according to an accident investigation report issued by the Ruian Emergency Management Bureau titled “Report on the ‘May 7’ Struck-by Object Accident at Ruian Guangxin Machinery Parts Factory”: On May 7, 2024, a struck-by object accident occurred at Ruian Guangxin Machinery Parts Factory, resulting in injuries to worker Liu XX, who later died the same day after failed emergency treatment.

Accident Details

At around 9:00 AM on May 7, 2024, Liu XX was operating a bench grinder in the polishing workshop of Ruian Guangxin Machinery Parts Factory to polish metal parts. Due to improper operation, the metal part became stuck in the grinding wheel, causing the high-speed rotating wheel to shatter. A fragment flew off and struck Liu XX in the chest, causing him to collapse unconscious.

A coworker in the same workshop, Hong XX, immediately shut off the workshop’s power and notified the owner, Xu XX, who arrived promptly and performed CPR on Liu XX. Shortly afterward, emergency medical personnel arrived and attempted resuscitation. However, by approximately 9:40 AM, Liu XX was pronounced dead due to failed rescue efforts.

What is an Angle Grinder?

According to GB/T 3883.3-2007, Safety of Handheld Motor-Operated Electric Tools – Part 2, Section 3.104.1, an angle grinder is defined as:

A tool with a rotating shaft perpendicular to the motor shaft, used for grinding and polishing tasks with its circumferential and end surfaces. It is also classified under the same category as angle disc sanders and angle polishers. Common angle grinder brands include Bosch, Dongcheng, Stanley, Lixiang, Hitachi, Tielang, and Gomes.

An angle grinder (ANGLE GRINDER), also known as a disc grinder or disc sander, has consistently ranked #1 on the list of most dangerous power tools!

Why is it the Most Dangerous?

- It is lightweight, portable, and widely used, with many users modifying it for unintended purposes.

- Angle grinders are originally designed for grinding, which is relatively safe.

- However, when used for cutting, the danger level increases significantly. Using saw blades for cutting is especially hazardous!

Many people attribute the danger to its high rotational speed, but speed alone is not the primary cause of accidents.

The real culprits are lack of tool knowledge and complacency!

Top 10 Causes of Angle Grinder Accidents

- Operating the grinder with one hand

- Using cutting discs for grinding and vice versa

- Using incompatible or defective discs

- Installing non-grinder discs for cutting

- “Reverse” pulling while cutting

- Cutting all the way through in one pass

- Cutting materials without proper support

- Removing the safety guard

- Using grinding discs on thin-walled or flexible materials

- Using grinding discs to cut grooves or grind narrow gaps

Similar Case: Fatal Handheld Grinder Accident

A grinder without a safety guard is a killing machine!

Grinders are among the most commonly used auxiliary equipment in various industries. However, due to their brittle nature, high-speed rotation, and frequent use, even minor negligence can lead to severe injuries.

Factors such as improper installation, incorrect usage, and failure to follow safety procedures directly impact worker safety. A single mistake can result in serious or fatal injuries, making strict adherence to safety guidelines essential.

Detailed Safety Guide for Grinding Wheels: Accident Warnings and Protective Measures

Case Study: Grinding Wheel Accident

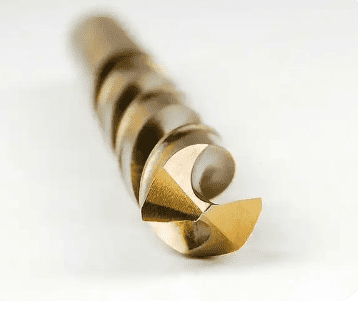

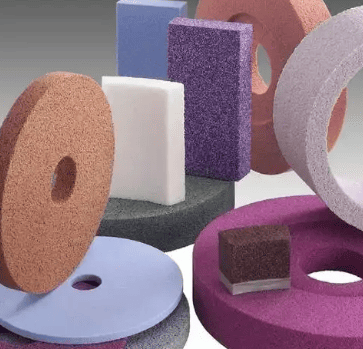

Grinding wheels, as core tools in abrasive machining, must be selected and used with extreme caution. Any negligence can lead to severe accidents.

Example Incident:

On September 11 of last year, a grinding wheel fracture accident occurred at a construction site in Shenzhen. A worker was using a grinder to cut a steel cable when the wheel suddenly shattered. A flying fragment struck the worker’s neck, resulting in an instant fatality. This tragic incident serves as a stark reminder of the critical importance of grinding wheel safety.

▲ Incident Summary and Warning

The Shenzhen accident, where a worker died due to a grinding wheel fracture, has raised widespread concerns about grinding wheel safety.

▲ Accident Cause Analysis

Preliminary investigations revealed that:

- The grinder lacked a protective guard, leaving the operation unsafe.

- The worker failed to conduct a proper safety inspection before use, creating hidden risks.

Thus, the primary causes were the absence of a guard and lack of pre-use inspection.

02 Safety Measures for Grinding Wheel Use

▲ Selection and Inspection

To prevent similar accidents, the following measures must be implemented:

- Only purchase genuine grinding wheels and conduct strict inspections to ensure professional-grade quality.

- Xinhuatong, with over a decade of manufacturing expertise, adheres to strict quality control, using premium materials to ensure every wheel meets high standards.

▲ Personal Protective Equipment (PPE) Requirements

The following precautions are mandatory:

- Wear fitted protective clothing—avoid loose jackets, and never work shirtless, in vests, shorts, or sandals.

- Always use safety gloves and goggles to prevent hazardous exposure.

▲ Workspace and Operational Standards

- Keep the work area clean—flammable or explosive materials must never be present.

- Grinders must have protective guards installed.

- Ensure the workspace is safe and organized to minimize risks.

- Before operation, manually adjust to maintain a safe distance between the wheel and workpiece.

- Approach the workpiece slowly, applying moderate and even pressure—no sudden impacts!

- Operators must remain vigilant—if any abnormalities occur, stop immediately and retract the wheel.

Additional Prohibitions:

- Never cut workpieces containing flammable/explosive materials or sealed containers.

- Only trained personnel should operate grinders.

- No bystanders are allowed near the grinder during operation.

Conclusion

Grinding wheels and angle grinders are high-risk tools that demand strict safety protocols. Proper training, correct usage, and protective measures are essential to prevent fatal accidents. Always prioritize safety—complacency can be deadly.