Can a grinding wheel cut metal?

Principle of Grinding Wheel Cutting

Grinding wheels can cut metal. Grinding wheel cutting utilizes the friction between a high-speed rotating grinding wheel disc and the metal material to remove material through abrasion, thereby achieving the cutting purpose. This method is widely applied in metal material analysis and is suitable for various metals, including steel, aluminum alloys, copper alloys, and others.

Advantages of Grinding Wheel Cutting

- Wide Applicability: Capable of cutting a variety of metal materials, including common steels, aluminum alloys, and copper alloys. It performs well on materials with a broad range of hardness.

- High Cutting Efficiency: Generally, grinding wheel cutting is relatively fast, allowing for quick completion of sample cutting, making it suitable for large-scale cutting tasks.

- Low Equipment Cost: Grinding wheel cutting equipment has a relatively simple structure, primarily consisting of a motor, grinding wheel disc, clamping device, and cooling system. Its purchase and maintenance costs are low, making it suitable for laboratories or small businesses with limited budgets.

Disadvantages of Grinding Wheel Cutting

- Large Heat-Affected Zone: Due to the significant friction during grinding wheel cutting, a large amount of heat is generated, causing microstructural changes near the cutting area of the sample and forming a heat-affected zone. This may interfere with accurate analysis of the original microstructure for materials with strict requirements.

- Poor Cut Surface Quality: The surface of samples after grinding wheel cutting is usually rough, with visible scratches and residual abrasive particles, requiring additional time and effort in subsequent grinding and polishing processes.

Can Grinding Wheel Discs Cut Metal?

Grinding wheel discs can be used for cutting metal, but the appropriate disc must be selected based on the type and thickness of the metal, and operational safety must be ensured.

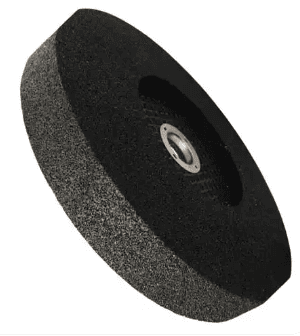

Composition and Characteristics of Grinding Wheel Discs

Grinding wheel discs are typically composed of abrasives, binders, and pores.

- Abrasives: The cutting component of the disc, commonly made of materials such as aluminum oxide or silicon carbide.

- Binder: The material that bonds the abrasives together to form the disc, such as ceramic or resin.

- Pores: Formed during the manufacturing process to aid in heat dissipation and chip removal.

Due to their high hardness and wear resistance, grinding wheel discs are suitable for grinding and cutting hard materials, including metals.

Applications of Grinding Wheel Discs in Metal Cutting

In practical applications, grinding wheel discs are indeed widely used for metal cutting, especially in scenarios requiring high precision, such as mechanical machining and mold manufacturing.

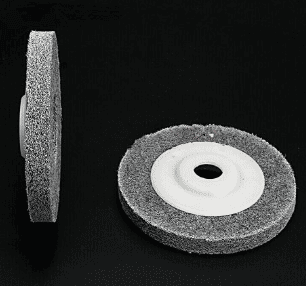

However, not all grinding wheel discs are suitable for cutting metal. Different types of metals and varying thicknesses of metal sheets require discs with different specifications and materials. For example, high-hardness and high-strength metals require discs with finer abrasives and stronger binders to ensure cutting effectiveness and tool longevity.

Precautions for Cutting Metal with Grinding Wheel Discs

While grinding wheel discs can cut metal, the following precautions must be observed during operation:

- Safety Protection: Cutting metal generates significant sparks and dust. Operators must wear protective gear such as goggles and masks to ensure safety.

- Proper Disc Selection: Choose the appropriate disc based on the metal type and thickness to avoid poor cutting results or tool damage.

- Cutting Speed Control: Excessive speed can cause overheating, accelerated wear, or even safety hazards. Maintain a stable and controlled cutting speed.

- Regular Inspection and Replacement: Grinding wheel discs gradually wear out during use. Regularly check their condition and replace them promptly to ensure cutting quality and operational safety.

Conclusion

Grinding wheel discs can effectively cut metal, but the correct disc must be selected based on the specific application, and safety measures must be strictly followed during operation. Proper tool maintenance is also essential to ensure optimal performance and safety.

Additional Notes on Grinding Wheel Specifications

For reference, grinding wheel models are often marked with codes indicating their dimensions, abrasive type, grit size, hardness grade, structure, bond type, and maximum operating speed (e.g., SPA 400×100×127 A 60 L 5 B 35). Understanding these markings helps in selecting the right wheel for specific metal-cutting tasks.

By considering these factors, users can maximize the efficiency and safety of grinding wheel cutting in metalworking applications.

Grinding Wheels for Metal Cutting

1. Principle of Grinding Wheel Cutting

Grinding wheels can cut metal. Grinding wheel cutting utilizes the friction between a high-speed rotating grinding wheel disc and the metal material to remove material through abrasion, thereby achieving the cutting purpose. This method is widely applied in metal material analysis and is suitable for various metals, including steel, aluminum alloys, copper alloys, and others.

2. Advantages of Grinding Wheel Cutting

- Wide Applicability: Capable of cutting a variety of metal materials, including common steels, aluminum alloys, and copper alloys. It performs well on materials with a broad range of hardness.

- High Cutting Efficiency: Generally, grinding wheel cutting is relatively fast, allowing for quick completion of sample cutting, making it suitable for large-scale cutting tasks.

- Low Equipment Cost: Grinding wheel cutting equipment has a relatively simple structure, primarily consisting of a motor, grinding wheel disc, clamping device, and cooling system. Its purchase and maintenance costs are low, making it suitable for laboratories or small businesses with limited budgets.

3. Disadvantages of Grinding Wheel Cutting

- Large Heat-Affected Zone: Due to the significant friction during grinding wheel cutting, a large amount of heat is generated, causing microstructural changes near the cutting area of the sample and forming a heat-affected zone. This may interfere with accurate analysis of the original microstructure for materials with strict requirements.

- Poor Cut Surface Quality: The surface of samples after grinding wheel cutting is usually rough, with visible scratches and residual abrasive particles, requiring additional time and effort in subsequent grinding and polishing processes.

4. Can Grinding Wheel Discs Cut Metal?

Grinding wheel discs can be used for cutting metal, but the appropriate disc must be selected based on the type and thickness of the metal, and operational safety must be ensured.

5. Composition and Characteristics of Grinding Wheel Discs

Grinding wheel discs are typically composed of abrasives, binders, and pores.

- Abrasives: The cutting component of the disc, commonly made of materials such as aluminum oxide or silicon carbide.

- Binder: The material that bonds the abrasives together to form the disc, such as ceramic or resin.

- Pores: Formed during the manufacturing process to aid in heat dissipation and chip removal.

Due to their high hardness and wear resistance, grinding wheel discs are suitable for grinding and cutting hard materials, including metals.

6. Applications of Grinding Wheel Discs in Metal Cutting

In practical applications, grinding wheel discs are indeed widely used for metal cutting, especially in scenarios requiring high precision, such as mechanical machining and mold manufacturing.

However, not all grinding wheel discs are suitable for cutting metal. Different types of metals and varying thicknesses of metal sheets require discs with different specifications and materials. For example, high-hardness and high-strength metals require discs with finer abrasives and stronger binders to ensure cutting effectiveness and tool longevity.

7. Precautions for Cutting Metal with Grinding Wheel Discs

While grinding wheel discs can cut metal, the following precautions must be observed during operation:

- Safety Protection: Cutting metal generates significant sparks and dust. Operators must wear protective gear such as goggles and masks to ensure safety.

- Proper Disc Selection: Choose the appropriate disc based on the metal type and thickness to avoid poor cutting results or tool damage.

- Cutting Speed Control: Excessive speed can cause overheating, accelerated wear, or even safety hazards. Maintain a stable and controlled cutting speed.

- Regular Inspection and Replacement: Grinding wheel discs gradually wear out during use. Regularly check their condition and replace them promptly to ensure cutting quality and operational safety.

Conclusion

Grinding wheel discs can effectively cut metal, but the correct disc must be selected based on the specific application, and safety measures must be strictly followed during operation. Proper tool maintenance is also essential to ensure optimal performance and safety.

Additional Notes on Grinding Wheel Specifications

For reference, grinding wheel models are often marked with codes indicating their dimensions, abrasive type, grit size, hardness grade, structure, bond type, and maximum operating speed (e.g., SPA 400×100×127 A 60 L 5 B 35). Understanding these markings helps in selecting the right wheel for specific metal-cutting tasks.

By considering these factors, users can maximize the efficiency and safety of grinding wheel cutting in metalworking applications.

One Comment