What is a 60 grit grinding wheel used for?

A 60-grit grinding wheel means its abrasive particles can pass through a sieve with 60 meshes per inch, while an 80-grit grinding wheel’s particles can pass through a sieve with 80 meshes per inch. Therefore, the abrasive particles of an 80-grit grinding wheel are finer than those of a 60-grit wheel. When selecting a grinding wheel, the appropriate grit size should be determined based on specific processing requirements and material properties. For example, a 60-grit grinding wheel is more suitable for rough machining applications that require rapid material removal.

Differences Between 60-Grit and 80-Grit Grinding Wheels and Their Applications in Copper Grinding

- Basic Differences Between 60-Grit and 80-Grit Grinding Wheels

The grit size of a grinding wheel, which refers to the size of the abrasive particles, is an important consideration when selecting a grinding wheel. The main differences between 60-grit and 80-grit grinding wheels lie in their abrasive particle sizes and application scenarios. - Abrasive Particle Size:

- The abrasive particles of a 60-grit grinding wheel are relatively larger, which means it can remove material more quickly but may result in a rougher surface after grinding.

- In contrast, the abrasive particles of an 80-grit grinding wheel are smaller, resulting in a smoother surface after grinding.

- Application Scenarios:

- 60-grit grinding wheels are typically used for rough grinding or applications requiring the removal of large amounts of material, such as initial grinding of blanks or rapid stock removal for metal materials.

- 80-grit grinding wheels are more suitable for semi-finishing or finishing processes that require higher surface smoothness.

- Grit Size Selection for Rough Grinding

For rough grinding, grinding wheels with lower grit sizes, such as 60-grit, are usually selected to improve grinding efficiency and material removal rates. Such wheels can quickly flatten uneven surfaces on workpieces, laying the foundation for subsequent finishing processes. - Grinding Wheel Selection for Copper Workpieces

When grinding copper workpieces, coarser-grit grinding wheels should be selected because copper has good thermal conductivity and can easily cause wheel clogging. Coarser-grit wheels provide larger chip clearance, preventing wheel clogging and facilitating heat dissipation. Specifically, grinding wheels with grit sizes ranging from #46 to #60 can be chosen for copper grinding. - Basic Steps for Grinding Thin Copper Workpieces and Copper Plates on a Surface Grinder

- Preparation:

- Check that all components of the surface grinder are functioning properly. Select an appropriate grinding wheel based on the workpiece dimensions and processing requirements, and install it securely. For copper grinding, prepare an adequate amount of coolant to prevent overheating of the grinding wheel.

- Workpiece Fixturing:

- Place the copper workpiece or plate on a magnetic chuck, ensuring it is firmly secured to prevent displacement or splashing during grinding. For non-magnetic materials, use suitable fixtures for fixation.

- Rough Grinding Stage:

- Use a lower-grit grinding wheel (e.g., 60-grit) for rough grinding to quickly remove material and flatten uneven surfaces on the workpiece. Adjust the wheel speed and feed rate promptly to maintain a stable grinding process.

- Finish Grinding Stage:

- After achieving a certain level of surface flatness, switch to a higher-grit grinding wheel (e.g., 80-grit) for finish grinding. Reduce the wheel speed and feed rate at this stage to obtain a smoother surface finish.

- Inspection and Measurement:

- After grinding, use precision measuring tools to inspect the workpiece dimensions and surface roughness to ensure they meet the drawing requirements. For non-conforming workpieces, rework or scrap them as necessary.

- Cleaning and Maintenance:

- Clean the worktable and surrounding area of the surface grinder to ensure the equipment remains in good working condition. Regularly inspect the grinding wheel for wear and replace it promptly to maintain grinding effectiveness and processing quality.

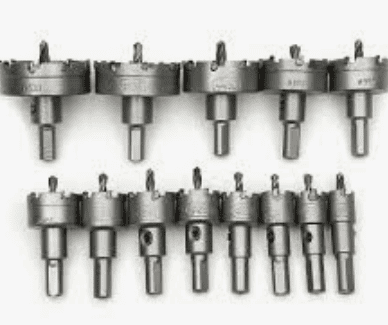

Grinding Wheel Specifications for Drill Bit Grinding

For drill bit grinding, 60-grit or 80-grit grinding wheels are generally used.

Regarding the specific models of grinding wheels used for drill bit grinding, the following details are provided:

- Grinding Wheel Model Selection

The selection of a grinding wheel is crucial for the quality of drill bit grinding. Different wheel models are suitable for different grinding tasks and materials. Generally, 60-grit and 80-grit grinding wheels are commonly used for drill bit grinding. These wheels offer appropriate hardness and wear resistance, ensuring effective grinding of drill bits while maintaining good durability. - Characteristics and Applications of 60-Grit Grinding Wheels

A 60-grit grinding wheel is a medium-grit wheel suitable for grinding most conventional metal materials. It has strong grinding capabilities and good durability, making it a popular choice for many drilling operations. When grinding drill bits, it provides stable grinding performance and ensures bit quality. - Characteristics and Applications of 80-Grit Grinding Wheels

Compared to 60-grit wheels, 80-grit wheels have finer abrasive particles. They are suitable for grinding tasks requiring higher precision, particularly excelling in grinding hard materials like carbide. When grinding drill bits, 80-grit wheels produce smoother grinding surfaces, making them ideal for applications demanding high drill bit precision. - Selection Based on Practical Conditions

When selecting a grinding wheel, in addition to considering the model, the specific grinding task, material type, and processing requirements must also be taken into account. Different processing conditions and materials may require different wheel models to achieve optimal grinding results. Therefore, a comprehensive evaluation should be conducted to select the most suitable grinding wheel model.

In summary, 60-grit or 80-grit grinding wheels are generally used for drill bit grinding, with the specific choice depending on the processing task, material type, and requirements. Proper selection and use of grinding wheels ensure drill bit quality and improve processing efficiency.

Interpretation of Grinding Wheel Model Markings and Their Meanings

Detailed Explanation of Grinding Wheel Markings

SPA 400100127 A 60 L 5 B 35

- SPA: This is the shape code of the grinding wheel, representing its specific geometric shape.

- 400: Represents the outer diameter of the grinding wheel, which is 400 mm.

- 100: Indicates the thickness of the grinding wheel, referring to its width or height, which is 100 mm.

- 127: Refers to the bore diameter of the grinding wheel, which is 127 mm.

- A: As the abrasive code, it indicates that the wheel uses brown aluminum oxide as the abrasive. This material offers good toughness, high hardness, and affordability, making it suitable for grinding carbon steel, alloy steel, malleable cast iron, and hard bronze.

- 60: Represents the grit size of the grinding wheel, i.e., the size of the abrasive particles. Grit size significantly affects processing quality. Generally, finer abrasive particles result in smaller surface roughness (Ra) values, meaning higher surface finish.

- L: The hardness code, indicating the hardness grade of the grinding wheel.

- 5: The structure number, providing further details about the wheel’s structure.

- B: The bond code, used to distinguish different types of bonds.

- 35: The maximum operating speed, in meters per second, indicating the highest rotational speed during grinding.

Next, we further explore the types and characteristics of abrasives. Abrasives are mainly divided into oxide-based, carbide-based, and high-hardness synthetic diamond categories. Each type has unique colors, hardness levels, and application ranges. For example, brown aluminum oxide abrasives are widely popular due to their good toughness, high hardness, and cost-effectiveness, making them particularly suitable for grinding carbon steel and alloy steel. White aluminum oxide, with its brittle and hard characteristics, excels in grinding hardened steel and high-speed steel. Additionally, there are other types of abrasives, such as chromium corundum, black silicon carbide, and green silicon carbide, each with distinct colors and properties to meet various grinding needs.

At the same time, grit size is a key factor affecting processing quality. Finer grit sizes result in smaller surface roughness values, meaning higher surface finishes. Therefore, when selecting a grinding wheel, the grit size should be adjusted based on specific processing requirements.

Finally, the maximum operating speed of the grinding wheel must also be considered. This refers to the highest rotational speed during grinding, directly impacting the wheel’s performance and lifespan. When selecting a wheel, ensure its maximum operating speed meets actual processing needs to guarantee safe and efficient production.

8#: Represents the bore diameter of the grinding wheel, which is 8 mm.

25003150: Indicates the maximum operating speed of the grinding wheel, in revolutions per minute (rpm), representing the highest rotational speed range during grinding.

150#: Refers to the grit size of the grinding wheel, meaning the abrasive particle size is 150-grit.

80100: Represents the thickness of the grinding wheel, referring to its width or height range, which is between 80 and 100 mm.

Below are several groups of different grinding wheel models and their related parameters:

10#: Bore diameter of 10 mm, maximum operating speed between 2000 and 2500 rpm, abrasive particle size of 180-grit, and thickness range of 63 to 80 mm.

12#: Bore diameter of 12 mm, maximum operating speed between 1600 and 2000 rpm, abrasive particle size of 220-grit, and thickness range of 50 to 63 mm.

And so on. Each grinding wheel model has specific parameters for bore diameter, maximum operating speed, abrasive particle size, and thickness range. The selection of these parameters is crucial for meeting different grinding needs.

1.52.5: This range represents the width or height of the grinding wheel, i.e., its thickness, which is between 1.5 and 2.5 mm.

100#: This indicates the grit size of the grinding wheel, meaning the abrasive particle size is 100-grit.

125160: This refers to the width or height range of the grinding wheel, i.e., its thickness range, which is from 125 to 160 mm.

W1.5: This marking may represent a specific characteristic or classification of the grinding wheel. Its exact meaning requires reference to relevant standards or literature.

Please note that the specific meanings and units of these parameters may vary across different industrial fields or standards. Therefore, in practical applications, carefully verify the definitions and units of each parameter to ensure correct understanding and use of the grinding wheel.

1.01.5: This range similarly represents the width or height of the grinding wheel, i.e., its thickness, which is between 1.0 and 1.5 mm.

120#: This indicates the grit size of the grinding wheel, meaning the abrasive particle size is 120-grit.

100125: This refers to the width or height range of the grinding wheel, i.e., its thickness range, which is from 100 to 125 mm.

W1.0: This marking may symbolize a specific attribute or classification of the grinding wheel. Its exact meaning requires consultation of relevant standards or literature.

Similarly, the specific meanings and units of these parameters may vary across different industrial applications or standards. Therefore, in practical operations, carefully verify the definitions and units of each parameter to ensure accurate understanding and use of the grinding wheel.

(3) Bond

The strength, impact resistance, heat resistance, and corrosion resistance of a grinding wheel are all closely tied to the critical role of the bond. The type and performance of the bond directly affect the wheel’s application range and effectiveness. Below are several common bond types and their characteristics:

- Ceramic bond, coded as V, is primarily composed of clay, feldspar, and talc. It offers good water, acid, alkali, and heat resistance, along with affordability, and can achieve speeds up to 35 m/s. However, it is relatively brittle and less prone to clogging, making it particularly suitable for grinding narrow slots in cutting parts.

- Resin bond, coded as B, is produced by the reaction of phenol and formaldehyde. It has high strength and toughness, making it suitable for various grinding and polishing tasks. However, its heat resistance is relatively poor, so temperature control is necessary during use.

1) High strength and good elasticity

2) Slightly inferior heat and corrosion resistance

3) Recommended storage time should not exceed one year

For grinding narrow slots, cutting, and polishing tasks, rubber-bonded wheels, coded as R and primarily made of synthetic rubber, can be selected. This bond combines high strength with good elasticity, effectively improving wheel performance. However, its heat and corrosion resistance are relatively weak, so environmental conditions must be controlled during use, and the recommended storage time should be observed.

1) High strength and good elasticity

2) Excellent yielding properties, effectively absorbing vibrations

3) Poor oil resistance

For grinding narrow slots and forming surfaces, magnesite bond, coded as Mg, can be chosen. This bond not only offers high strength and good elasticity but also excellent yielding properties, effectively absorbing vibrations. However, it is not oil-resistant, so contact with oil-based substances must be avoided during use.

1) Good self-sharpening properties

2) Low heat generation during grinding

For grinding large surface areas and metals with poor thermal conductivity, bonds with good self-sharpening properties and low grinding heat are recommended. Such bonds not only effectively reduce heat generation during grinding but also maintain good self-sharpening properties, ensuring lasting grinding performance.