What is the difference between pink and white grinding wheels?

What is the difference between pink and white grinding wheels?

- White grinding wheels: Suitable for grinding hard materials such as high-speed steel and tool steel.

- Pink grinding wheels: Suitable for grinding heat-treated hard materials such as stainless steel and titanium alloys.

Choosing the Right Abrasive Tool is Crucial!

When working with various materials, angle grinders are incredibly versatile tools. Simply plug them in, give them a spin, and they can quickly handle all kinds of material processing. If you encounter uneven cuts or burrs, a quick pass with a grinding disc will smooth things out. For cutting tasks, cutting discs are used—high-speed rotation allows them to slice through different materials with ease.

There is a wide variety of abrasive tools, each specialized for different applications. The three most common types for angle grinders are grinding discs, cutting discs, and flap discs. Today, we’ll break down the differences between them to help you make the right choice.

Grinding Discs: The Go-To for Grinding 💪

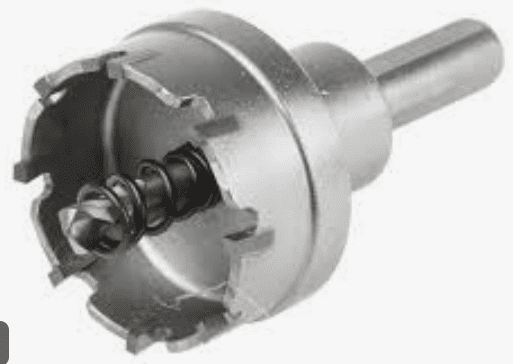

Grinding discs are primarily used for grinding operations and are typically thicker. They are made by mixing abrasives with a bonding agent, then pressing and firing them into shape. The quality and efficiency of grinding depend on the abrasive material and manufacturing process.

Grinding discs can be categorized by:

- Abrasive type:

- Conventional abrasives (e.g., aluminum oxide, silicon carbide)

- Super abrasives (e.g., diamond, cubic boron nitride)

- Bonding agent:

- Metal-bonded, rubber-bonded, resin-bonded, ceramic-bonded, etc.

Understanding these distinctions helps you select the most suitable grinding disc for your needs.

Cutting Discs: The Metal-Cutting Powerhouse 🔪

Cutting discs are designed for slicing through metal, especially those reinforced with fiberglass, resin, and abrasives for high impact and bending resistance. Common types include:

- Resin-bonded cutting discs: Made with resin and abrasives, ideal for cutting hard metals with high efficiency and precision.

- Diamond cutting discs: Composed of a steel core and diamond segments, mainly used for non-metallic materials like stone, ceramics, and concrete.

Flap Discs: The Surface Finishing Experts 🧹

Flap discs are used for surface polishing and finishing. Their surfaces consist of fine aluminum oxide or silicon carbide grains that smooth out workpieces through high-speed rotation. They come in various grit sizes (from coarse to ultra-fine) to achieve different finishes. Choosing the right grit depends on your specific requirements.

Key Differences Between Yellow, Green, and White Grinding Wheels

- Hardness Differences:

- Yellow wheels: Hardness varies based on abrasive and bond type (color alone is not a definitive indicator).

- Green wheels: Medium hardness, typically between black and blue wheels.

- White wheels: Made with white aluminum oxide, hardness depends on abrasive and bond composition.

- Abrasive & Bond Color:

- Wheel color is determined by either the abrasive or bond material (e.g., white wheels use white aluminum oxide).

- The same abrasive can produce different wheel colors with different bonds (e.g., ceramic-bonded wheels are white, while resin-bonded may appear gray-brown).

- Bond Types:

- Wheels can be ceramic-bonded, resin-bonded, rubber-bonded, etc.

- Color does not always indicate bond type, as it primarily reflects the abrasive or bond’s natural color.

Summary: The main differences between yellow, green, and white wheels lie in hardness, abrasive/bond color, and possible bond types. Selecting the right wheel depends on the specific grinding application.

Grinding Wheel Selection Guide for Metal Grinding

1. Common Grinding Wheel Types

- Black wheels: For general steel (e.g., mild steel, high-speed steel).

- White wheels: For hard materials (e.g., high-speed steel, tool steel).

- Pink wheels: For heat-resistant alloys (e.g., stainless steel, titanium).

- Green wheels: For non-metallics (e.g., carbide, ceramics).

- Gray wheels: For soft metals (e.g., cast iron, copper, aluminum, brass).

2. Material-Specific Selection

- Mild steel / Carbon steel → Black wheels

- High-speed steel / Tool steel → White wheels

- Stainless steel / Titanium → Pink wheels

- Carbide / Ceramics → Green wheels

- Cast iron / Copper / Aluminum / Brass → Gray wheels

3. Wheel Shape for Different Grinding Operations

- Surface grinding → Flat-faced wheels

- Internal grinding → Cylindrical wheels

- External grinding → Tapered wheels

- Combined external & surface grinding → Notched wheels

4. Key Considerations

- Always match the wheel to the workpiece material and shape.

- Ensure wheel dimensions (diameter & thickness) suit the grinder’s specifications.

- Properly mount and balance wheels to avoid vibration, ensuring smooth operation and prolonging grinder life.

Conclusion

Selecting the right grinding wheel is critical for efficiency, finish quality, and machine longevity. Understanding material compatibility, wheel types, and proper usage ensures optimal results in metal grinding applications.