What is the main purpose of grinding?

The main uses of grinding include machining various internal and external cylindrical surfaces, conical surfaces, and flat surfaces of workpieces, as well as special and complex formed surfaces such as threads, gears, and splines. Grinding can be used to process a variety of materials, including high-hardness metals and non-metallic materials such as hardened steel, high-strength alloy steel, carbide, glass, ceramics, and marble. It is a mechanical material removal method that involves using abrasives and grinding tools to cut away excess material from workpieces. Grinding is one of the most widely used material removal methods.

In mechanical machining, grinding belongs to the category of precision machining (which includes rough machining, precision machining, heat treatment, etc.), characterized by minimal material removal and high precision. It is widely applied in the machinery manufacturing industry. For parts made of heat-treated carbon tool steel or carburized and quenched steel, grinding often produces a large number of regularly arranged cracks—grinding cracks—on surfaces that are essentially perpendicular to the grinding direction. These cracks not only affect the appearance of the part but also directly impact its quality.

Principles of Grinding

Grinding is a cutting process that uses high-speed rotating grinding tools (such as grinding wheels) to machine workpiece surfaces. It can process various internal and external cylindrical surfaces, conical surfaces, and flat surfaces, as well as special and complex formed surfaces like threads, gears, and splines. Due to the high hardness of abrasive grains and the self-sharpening nature of grinding tools, grinding can be used to process various materials, including hardened steel, high-strength alloy steel, carbide, glass, ceramics, and marble.

Grinding speed refers to the linear speed of the grinding wheel, typically 30–35 m/s. When it exceeds 45 m/s, it is called high-speed grinding. Grinding is usually used for semi-finishing and finishing, achieving precision levels of IT8–5 or higher. The surface roughness for general grinding is Ra 1.25–0.16 μm, precision grinding Ra 0.16–0.04 μm, ultra-precision grinding Ra 0.04–0.01 μm, and mirror grinding can achieve Ra below 0.01 μm.

The specific power (or specific energy consumption, i.e., the energy consumed per unit volume of material removed) of grinding is higher than that of conventional cutting, while the metal removal rate is lower. Therefore, workpieces are usually pre-processed by other cutting methods to remove most of the material, leaving only 0.1–1 mm or less for grinding. With the development of high-efficiency grinding methods such as creep-feed grinding and high-speed grinding, it is now possible to shape parts directly from raw blanks. Grinding can also be used for rough machining, such as removing casting gates, forging flash, and the outer skin of steel ingots.

Types of Grinding

External Cylindrical Grinding

Primarily performed on external cylindrical grinding machines to grind the external cylindrical surfaces, conical surfaces, and shoulder end faces of shaft-type workpieces. During grinding, the workpiece rotates at a low speed. If the workpiece also moves longitudinally and the grinding wheel feeds transversely after each single or double longitudinal pass, it is called traverse grinding (Figure 1). If the grinding wheel width exceeds the length of the surface being ground, the workpiece does not move longitudinally, and the grinding wheel feeds continuously in the transverse direction, it is called plunge grinding. Plunge grinding is generally more efficient than traverse grinding. By dressing the grinding wheel into a specific shape, plunge grinding can produce formed external surfaces.

Internal Cylindrical Grinding

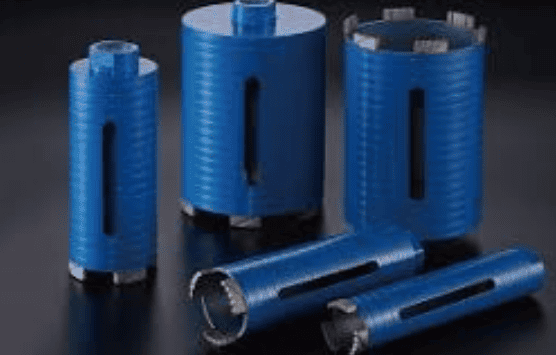

Mainly used on internal cylindrical grinding machines, universal external cylindrical grinding machines, and jig grinding machines to grind cylindrical holes (Figure 2), conical holes, and hole end faces of workpieces. Traverse grinding is typically used. For grinding formed internal surfaces, plunge grinding can be employed. On jig grinding machines, the workpiece is fixed on the table, and the grinding wheel not only rotates at high speed but also performs planetary motion around the centerline of the hole being ground. Due to the small diameter of the grinding wheel in internal grinding, the grinding speed is often below 30 m/s.

Surface Grinding

Primarily used on surface grinding machines to grind flat surfaces and grooves. There are two types of surface grinding:

- Peripheral Grinding (Figure 3): Uses the outer cylindrical surface of the grinding wheel, typically performed on horizontal-spindle surface grinding machines. Formed grinding wheels can also be used to machine various shaped surfaces.

- Face Grinding: Uses the end face of the grinding wheel, typically performed on vertical-spindle surface grinding machines.

Centerless Grinding

Generally performed on centerless grinding machines to grind external cylindrical surfaces. During grinding, the workpiece is not centered or supported by centers but is placed between the grinding wheel and the regulating wheel, supported by a blade below and driven to rotate by the regulating wheel. When the axes of the regulating wheel and grinding wheel are adjusted to intersect at 1°–6°, the workpiece rotates while automatically feeding longitudinally along the axis—this is called through-feed grinding (Figure 4). Through-feed grinding can only be used for external cylindrical surfaces.

For plunge centerless grinding, the axes of the regulating wheel and grinding wheel are adjusted to be parallel, and the workpiece is supported on the blade without axial movement while the grinding wheel feeds continuously in the transverse direction. Plunge centerless grinding can machine formed surfaces.

Centerless grinding can also be used for internal grinding. During processing, the external cylindrical surface of the workpiece is centered on rollers or support blocks, and an eccentric electromagnetic ring drives the workpiece to rotate while the grinding wheel extends into the hole for grinding. Here, the external surface serves as the reference to ensure concentricity between the internal and external surfaces. Centerless internal grinding is often used on specialized bearing ring grinding machines to grind internal raceways of bearing rings.

Main Functions of Grinding

- Improve surface quality, enhancing precision and smoothness.

- Eliminate residual stress on workpiece surfaces, improving wear resistance and corrosion resistance.

Process Characteristics of Grinding

- High precision and low surface roughness.

- Multiple cutting edges, enabling micro-cutting.

- High grinding speed and high grinding temperature.

- Self-sharpening effect of grinding wheels.

- Large radial grinding force.

Applications of Grinding

Grinding has a very wide range of applications. It can process cast iron, carbon steel, alloy steel, and difficult-to-machine high-hardness materials. It can machine external cylinders, internal cylinders, flat surfaces, formed surfaces, threads, gear teeth, and tool sharpening. Additionally, grinding excels in high-precision requirements and hard material processing. For example, in aerospace and medical device industries, grinding meets high-precision demands. It is also effective for machining high-hardness materials like hardened steel.

Characteristics of Grinding Compared to Other Machining Methods

Compared to other cutting methods such as turning, milling, and planing, grinding has the following characteristics:

- High grinding speed, reaching 30–50 m/s; high grinding temperature, up to 1000°C–1500°C; very short grinding duration, around one ten-thousandth of a second.

- Grinding can achieve high machining precision and very low surface roughness.

- Grinding can process soft materials (e.g., unhardened steel, cast iron) as well as hard materials (e.g., hardened steel, ceramics, carbide) that other tools cannot machine.

- The depth of cut in grinding is very small, with only a thin layer of metal removed in a single pass.

- During grinding, fine abrasive particles fly off the grinding wheel, and metal chips splash from the workpiece. These particles can harm the operator’s eyes, and inhaling the dust can damage the lungs.

- Due to poor grinding wheel quality, improper storage, incorrect specifications, eccentric installation, or excessive feed rates, grinding wheels may break, causing serious injuries.

- During manual operations near rotating grinding wheels (e.g., tool grinding, workpiece cleaning, or incorrect wheel dressing), hands may come into contact with the wheel or other moving parts, resulting in injuries.

- Grinding can generate noise levels exceeding 110 dB, which can harm health if noise reduction measures are not taken.

Grinding Process

Grinding involves using abrasives and grinding tools to remove excess material from workpieces. Depending on process objectives and requirements, there are various grinding methods. To meet developmental needs, grinding technology is advancing toward precision, low roughness, high efficiency, high speed, and automation.

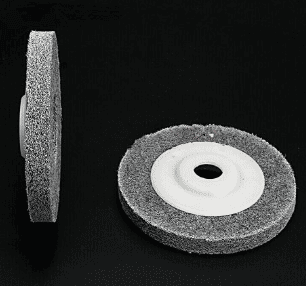

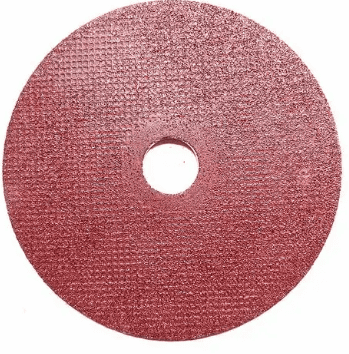

Grinding methods are diverse, but production primarily involves grinding with grinding wheels. For ease of use and management, grinding methods are typically categorized into four types based on grinding machine products and their processing objects:

- By Precision: Rough grinding, semi-finish grinding, finish grinding, mirror grinding, superfinishing.

- By Feed Method: Plunge grinding, traverse grinding, creep-feed grinding, no-feed grinding, pressure grinding, quantitative grinding.

- By Grinding Form: Belt grinding, centerless grinding, face grinding, peripheral grinding, wide-wheel grinding, form grinding, profile grinding, oscillation grinding, high-speed grinding, heavy-duty grinding, constant-pressure grinding, manual grinding, dry grinding, wet grinding, lapping, honing.

- By Machined Surface: External cylindrical grinding, internal cylindrical grinding, surface grinding, and tool sharpening (gear grinding, thread grinding).

Additionally, grinding can be classified by other criteria, such as:

- By Grinding Tool Type:

- Bonded abrasive methods (e.g., wheel grinding, honing, belt grinding, electrolytic grinding).

- Free abrasive methods (e.g., lapping, polishing, abrasive jet machining, abrasive flow machining, vibratory finishing).

- By Wheel Speed (Vs):

- Conventional grinding (Vs < 45 m/s).

- High-speed grinding (45 m/s ≤ Vs < 150 m/s).

- Ultra-high-speed grinding (Vs ≥ 150 m/s).

- By New Technologies: Magnetic abrasive finishing, electrochemical polishing, etc.

Detailed Explanation of Surface Grinding Methods and Characteristics

Surface grinding is an important machining method widely used for precision machining of hardened workpieces and parts with parallel surfaces. It can finely process parts like rolling bearing rings and piston rings, achieving flatness levels of 6–5 and surface roughness of Ra 1.0–0.2 μm.

Workpiece Clamping Methods

Clamping is a critical step in surface grinding. Typically, electromagnetic chucks are used for quick and effective workpiece installation, ensuring parallelism between the reference surface and the machined surface. For grinding two opposite surfaces as mutual references, this method significantly improves parallelism. For parts without suitable reference surfaces on the chuck, precision tools can be used for installation. Non-magnetic thin parts can be secured using vacuum chucks.

For small or thin-walled parts like keys, washers, and thin sleeves, the contact area with the table is small, leading to insufficient magnetic force. These parts may shift or even fly off under grinding forces, posing safety risks. Additional measures, such as using fences around or at the ends of the workpiece, are needed to ensure stability during grinding.

Grinding Methods and Characteristics

Peripheral Grinding: Features, Advantages, and Disadvantages

Surface grinding is mainly performed on surface grinding machines, with process characteristics similar to external and internal cylindrical grinding. The grinding wheel rotates as the primary motion while feeding longitudinally and transversely relative to the workpiece.

Peripheral grinding uses the cylindrical surface of the wheel. Its key feature is the relatively small contact area with the workpiece, resulting in low heat generation, effective chip removal, and good cooling, ensuring high precision. However, peripheral grinding is less efficient and more suitable for workpieces prone to warping. It is widely used in small-batch production.

Face Grinding: Features, Advantages, and Disadvantages

Face grinding uses the end face of the wheel. The wheel spindle is vertically mounted, offering high rigidity and enabling higher grinding parameters. The large contact area between the wheel and workpiece ensures high productivity. Face grinding is commonly used for mass production of parts like gearboxes and machine tool guideways.

However, face grinding is less precise than peripheral grinding. It generates more heat, and coolant has difficulty reaching the grinding zone, potentially causing thermal deformation. Uneven wheel wear can also affect precision.

What Surfaces Is Grinding Mainly Used for in Precision Machining?

Grinding is primarily used for precision machining of part surfaces, especially those requiring high precision and smoothness, such as flat, cylindrical, and hole surfaces.

What Is Grinding?

Grinding is a cutting method that uses abrasive tools (e.g., grinding wheels, honing heads) to contact and machine workpieces. Compared to other cutting methods, grinding offers high efficiency, precision, and smoothness.

Applications of Grinding

Grinding is used for surface machining of parts, particularly where high precision and smoothness are required (e.g., flat, cylindrical, and hole surfaces). Due to its ability to achieve high precision and smoothness, grinding is widely used in aerospace, automotive, electronics, and machinery industries.

Grinding Process Optimization

To achieve better results, grinding processes must be continuously optimized. This includes selecting suitable grinding tools, adjusting process parameters, and controlling the machining process. Additionally, grinding should follow a sequence of rough, medium, and fine grinding, with attention to the required precision and smoothness at each stage.

Conclusion

Grinding is a high-efficiency, high-precision, high-smoothness machining method, mainly used for part surfaces requiring high precision and smoothness, such as flat, cylindrical, and hole surfaces. In practice, grinding processes must be optimized to achieve better results.

One Comment