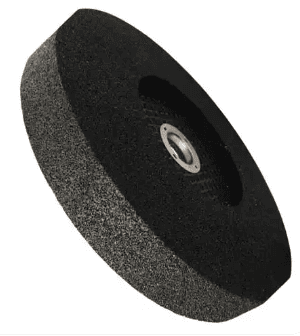

When should you throw away a grinding wheel?

When to Replace Grinding Discs

I. Service Life of Grinding Discs

Grinding discs are common wear-prone components in machinery, and their lifespan depends on factors such as machine type, operating environment, and material composition. Under normal conditions, grinding discs can last from several hundred to several thousand hours. However, they should be replaced in a timely manner based on wear levels to ensure proper machine operation.

II. Replacement Criteria for Grinding Discs

The decision to replace a grinding disc primarily depends on its wear condition. The following standards are typically used:

- Thickness Reduction: Replace when the disc thickness falls below 70% of its original standard thickness.

- Surface Damage: Replace if the disc shows scratches, cracks, or deformation.

- Operational Issues: Replace if the disc causes friction, jamming, or misalignment with other machine components.

Note: Replacement criteria may vary slightly depending on the type of machinery. Additionally, when replacing a grinding disc, inspect related components for maintenance or replacement needs.

III. Maintenance of Grinding Discs

To extend the lifespan of grinding discs, proper maintenance is essential:

- Regular Cleaning: Remove accumulated dust and debris from the disc surface.

- Balanced Operation: Ensure the disc operates smoothly with other machine parts to avoid uneven wear.

- Avoid Overloading: Excessive pressure or high rotational speeds can accelerate wear.

- Lubrication: Apply lubricant after replacement to reduce friction and wear.

By using grinding discs properly, replacing them when necessary, and performing regular maintenance, their service life can be extended, reducing downtime and improving production efficiency.

When to Replace Polishing Discs

Polishing discs are widely used in various industries, and their replacement timing depends on the following factors:

1. Degree of Wear

Replace the disc when visible wear marks (e.g., deep scratches, grooves) appear or when polishing efficiency declines significantly. Overused discs reduce productivity and may compromise safety.

2. Frequency of Use

High-frequency use (e.g., in metalworking or glass polishing) accelerates wear, requiring more frequent inspection and replacement.

3. Expiration of Service Life

Some manufacturers specify a recommended lifespan for polishing discs. Even if no visible wear is present, discs should be replaced upon reaching this limit to ensure performance and safety.

Detailed Explanation:

- Wear Assessment: Friction during use gradually wears down the disc. Replace it if surface damage or reduced polishing quality is observed.

- Impact of Usage Frequency: Intensive applications demand more frequent replacements.

- Importance of Scheduled Replacement: Follow manufacturer guidelines to avoid performance degradation and potential hazards.

Conclusion: Users should evaluate polishing discs based on wear, usage frequency, and manufacturer recommendations. Regular inspections and timely replacements ensure optimal performance and safety.

Key Takeaways:

- Grinding Discs: Replace at <70% thickness or if damaged. Maintain balance and lubrication.

- Polishing Discs: Replace when worn, inefficient, or expired. Check frequently in high-use scenarios.

- General Rule: Proactive replacement and maintenance enhance efficiency and safety.