How to choose a good circular saw, it only takes four steps to pick out the perfect electric circular saw

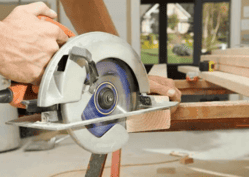

Wood art DIY is a very interesting project, looking at the pieces of rotten wood in their own hands into exquisite crafts, bringing a full sense of accomplishment and happiness, but wood and paper in the end is different, you need to pick a good electric circular saw, cutting wood can be more effort-saving!

There are many kinds of electric saws, and the electric circular saw is also a kind of electric saw, which is mainly powered by a single-phase series motor, and then the circular saw blade is driven by the transmission mechanism for sawing operations.

Of course, when making wood art, you can also use a manual saw, but in terms of work efficiency, or the electric circular saw is better, with it to help, especially for woodworking skills are not very mature partners, the use of electric circular saw cutting wood, easier to use, but also more security.

Although the electric circular saw only belongs to a small category of electric saws, it will also be difficult for many people when selecting, because the difference in structure and configuration will cause a huge difference in cutting effect, making it the key to determining the success or failure of wood art works.

However, if you want to choose a suitable electric circular saw or there is a way to find, we just need to start according to the three aspects of the electric circular saw type, saw blade and fuselage performance, we can easily find the electric circular saw that can really help you.

First, the type of bright electric circular saw

So the first thing we need to understand is the type of electric circular saw, according to the difference between the position of the motor and the saw blade, the electric circular saw can be divided into three different types: in-line, embedded and worm drive.

The difference in the type of circular saw determines the difference in their applicable working environment, and it is clear that the selection of electric circular saw can be more effectively combined with the needs of wood production to make decisions.

1.1 In-line circular saw

The motor of the in-line circular saw and the saw blade are vertically connected, and this kind of electric circular saw can drive the saw blade directly through the shaft of the motor, so as to achieve the effect of cutting.

Advantages: The fuselage is light, easy to operate, the most important thing is that the price is relatively cheap.

Disadvantages: limited horsepower, can not complete the strength of the work.

1.2 Worm drive circular saw

The motor of the worm drive circular saw and the saw blade present a parallel state, and then the motor increases the torque transmitted to the saw blade through the gear, so that the circular saw completes the cutting work.

Advantages: The power of this chainsaw is very powerful.

Disadvantages: Due to the complex structure, the fuselage is also relatively heavy, and the price is more expensive.

[Summary] Overall it seems that worm drive chainsaw is actually more suitable for use in large construction projects, and for general small wood art handmade, in-line circular saw is basically enough, lightweight fuselage is easier to control in the hand, and the price is relatively low, it can be described as economic and practical.

Second, look at the power supply mode

The biggest difference between the electric circular saw and the ordinary hand saw is that it is operated by electricity, and it is this power that gives the electric saw a strong power, saving more energy for the entire wood production process, but different power supply methods are applicable to different production occasions, let’s first understand the selection before making a decision.

At present, there are two common types, one is connected by cable lines to supply AC power to make the machine run, and the other is to provide power for the circular saw through a lithium battery to make it operate.

2.1 AC Power

Ac power supply is a more traditional form, usually see the end of the machine connected with a cable, want to use the electric circular saw to cut wood, just plug the wire plug into the socket, it can be used normally, now most power tools are taken this way of power supply.

Advantages:

The power supply is sufficient, and the torque is also larger, which can ensure the normal operation of the electric circular saw.

Cons:

Cable dragging is cumbersome and has security risks.

2.2 Lithium Battery

And another lithium battery power supply method is relatively more flexible, this kind of electric circular saw can rely on high-performance imported lithium batteries to help the machine power output, battery voltage is generally between 18-22v.

Advantages:

▲ Operation and carry are more convenient, just load the battery, gently press the power supply, you can carry out cutting operations, crisp.

▲ Less noise, wood production environment is more comfortable.

▲ Very low failure rate, convenient maintenance and maintenance.

Cons:

The battery power is limited, and it has to be charged after a period of use, which is more troublesome.

[Summary] After the above analysis, AC electric circular saw is more suitable for skilled partners, although the movement is not particularly convenient, but have to admit that the power of this kind of electric circular saw is still very strong.

The lithium battery electric circular saw is more suitable for some novice friends to use, not only easier to get started, but also higher safety, more than enough for some small wood art creation, and does not need to spend too much time to charge.

Third, fixed saw blade components

[Summary] After the above analysis, AC electric circular saw is more suitable for skilled partners, although the movement is not particularly convenient, but have to admit that the power of this kind of electric circular saw is still very strong.

The lithium battery electric circular saw is more suitable for some novice friends to use, not only easier to get started, but also higher safety, more than enough for some small wood art creation, and does not need to spend too much time to charge.

Third, fixed saw blade components

The reason why the chainsaw can successfully operate, in addition to the need for strong power, but also rely on the support of the core components, and so for the selection of saw blades, but also careful.

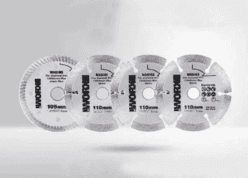

Under normal circumstances, we can select according to the two aspects of the material and tooth shape of the saw blade, both of which are important factors in determining the cutting ability of the saw blade, to understand these two points, when configuring the saw blade for the electric circular saw can also be more confident.

3.1 Select according to saw blade material

▲ High-speed steel saw blade

High speed steel saw blade is a kind of saw blade containing a lot of carbon, tungsten, molybdenum, chromium, vanadium and other elements, which will have high thermal hardness after heat treatment. Even when the cutting temperature is above 600 ° C, the hardness is still not significantly reduced, and the cutting speed of the saw blade can still reach more than 60m/min.

In general, the ordinary high-speed steel saw blade can be mainly used for steel, iron, copper, aluminum and other hard metal materials narrow and deep slot processing or cutting projects, of course, can also be used in non-metal milling processing.

▲ Carbide saw blade

So in contrast, carbide saw blade is a more commonly used for wood products processing cutting tools, it is commonly used in tungsten cobalt, tungsten titanium, impact resistance and wear resistance are very strong, heat deformation temperature up to 300℃-400℃.

▲ Diamond saw blade

Diamond saw blade is mainly composed of the matrix and the tool head two parts, its matrix is the main support part of the bonded tool head, and the tool head is the part of the cutting in the use process, this kind of saw blade is widely used in concrete, refractory materials, stone, ceramics and other hard and brittle materials processing.

So from this point of view, cemented carbide saw blade is more suitable for wood art DIY production process, not only the performance is strong, the price is relatively cheap, of course, diamond saw blade is also very good, but it is more suitable for cutting ceramics, marble and other materials.

Although the high-speed steel saw blade is very strong, but also very durable, but the price is much more expensive than the other two kinds of saw blades, used to make simple wood craft is a little overused.

3.2 Select according to saw blade tooth shape

Because in the wood production process, in most cases, alloy saw blades are used, so here is only for the tooth shape of the alloy saw blade to carry out an in-depth understanding.

▲ Left and right teeth

The left and right teeth are the most widely used, the cutting speed is fast, the grinding is relatively simple, and it is very suitable for cutting and cross-sawing all kinds of soft and hard solid wood profiles and density boards, multi-layer boards, particleboard, etc.

There is also a left and right teeth equipped with anti-rebound protection teeth, which can also be called dovetail teeth, suitable for longitudinal cutting a variety of tree joints, and another left and right teeth with negative front Angle because of the sharp teeth and good sawing quality, it is usually used for the sawing of the panel.

▲ Plain tooth

The flat tooth saw is rough, the cutting speed is slow, the grinding is the simplest, mainly can be used for the sawing of ordinary wood, the cost is low, this tooth shape is used in the small diameter of the aluminum saw blade, to keep cutting to reduce adhesion, or is used to slot saw blade to keep the groove bottom flat.

▲ Ladder flat teeth

There is also a tooth shape called ladder teeth, it can be said to be a combination of trapezoid teeth and flat teeth, grinding is more complex, sawing can reduce veneer cracking phenomenon, more suitable for a variety of single and double veneer wood-based board, fire board sawing.

▲ Inverted ladder teeth

The reverse ladder teeth are more commonly used in the bottom slot saw blade, such as when sawing the wood-based panel with double veneer, the groove saw adjusts the thickness to complete the groove of the bottom surface, and then the main saw completes the sawing processing of the plate, so as to prevent the saw edge from falling.

In summary, in the wood production process, for the work of solid wood crosscutting class, you can combine the left and right teeth and teeth, which is both efficient and can ensure that the cutting surface is smooth and smooth, and for the longitudinal cutting class project, it is more suitable for the combination of the left and right teeth and dovetail teeth, cutting faster and more efficient.

Four, explore the fuselage performance

The last thing to understand is the fuselage performance, a good electric circular saw in addition to the need for strong power, its accuracy, safety and convenience are also very important.

Before choosing an electric circular saw, find out its comprehensive performance, in order to better ensure that you find a good and reliable electric circular saw, so that the wood works produced can be more beautiful.

4.1 Accuracy

▲ Flexible Angle control

For any electric circular saw, its accuracy should be put in the first place, especially for wood art DIY, each cutting position is exquisite, more or less cutting will affect the final shape of the work.

But now most of the electric circular saws have the Angle adjustment function, the general fuselage side will be equipped with a clear Angle scale, partners in the production of wood works can combine their own needs, free Angle switch, more accurate control of the cutting position.

▲ With laser device

In addition, there are some electric circular saws equipped with a special laser device, we can cut according to the beam of the device, far more accurate than the pencil marking, especially for the cutting project with a more common distance, the laser device can also be more convenient and time-saving.

It is important to know that the above two configurations do not conflict, the more comprehensive in this regard, the higher the cutting accuracy of the electric circular saw, the use of laser devices should also pay attention to, although it is very convenient to use, but if in the case of direct sunlight outside, the laser may be invisible.

4.2 Security

▲ Can quickly dissipate heat

If the electric circular saw cannot dissipate its heat in time during operation, it will not only affect the life of the fuselage, but also easily cause burning events, which is very dangerous. Fortunately, the side of the electric circular saw is equipped with a special outlet, which effectively improves the heat dissipation efficiency and ensures the normal operation of the motor.

▲ Built-in overload protection

Is the so-called “day has the unexpected situation, people have the fortune”, even in the production of wood art manual will inevitably encounter the situation of overload saw, the phenomenon will make the equipment heat, serious words may also lead to equipment burn, and even hurt the person.

In order to avoid this dangerous phenomenon, some electric circular saws are now equipped with overload protection function, that is, when the motor exceeds the load, the machine will automatically cut off the power, safe and intelligent.

▲ With self-locking button design

In addition, there is a design on the electric circular saw that is very conducive to improving safety, that is, its self-locking switch design, in the saw in the form of buttons, hold down the button, the circular saw spindle will enter the locking state, so that when the saw blade is replaced, not only faster, but also effectively avoid the risk of being cut.

Although the electric circular saw is highly efficient, it is necessary to know that any advantage is a double-edged sword, especially for power tools, the existence of safety risks will increase, want to avoid the danger you have to sharpen your eyes when choosing, try to choose an electric circular saw with safety protection, and use can be more assured.

4.3 Convenience

▲ Handle is comfortable to hold

Then there is the convenience of the circular saw, which is a more abstract concept, how to be convenient, the comfortable and easy to use is called convenient, for example, the handle of the electric circular saw, most of the circular saw handles now use a soft adhesive design, so that even if held for a long time, the hand will not feel tired, but also play a certain anti-slip role.

▲ Can be external vacuum cleaner

In the process of wood art production, the most troublesome thing is the large amount of wood dust generated when cutting wood, which not only affects the line of sight, but also is not conducive to respiratory health.

However, if you look carefully, you will find that most electric circular saws are now equipped with a special dust suction interface on the body, which can be used to connect the external vacuum cleaner, thereby reducing the phenomenon of dust flying.

Do not underestimate the convenience of the electric circular saw, any key tool even if the function is powerful, but if the use is not smooth, still can not make wood works in line with their own mind, so the selection of this aspect should also pay attention.

Industrial News