Will a diamond blade cut copper?

Blades: Applications in Copper Cutting and Considerations for Soft Copper Turning

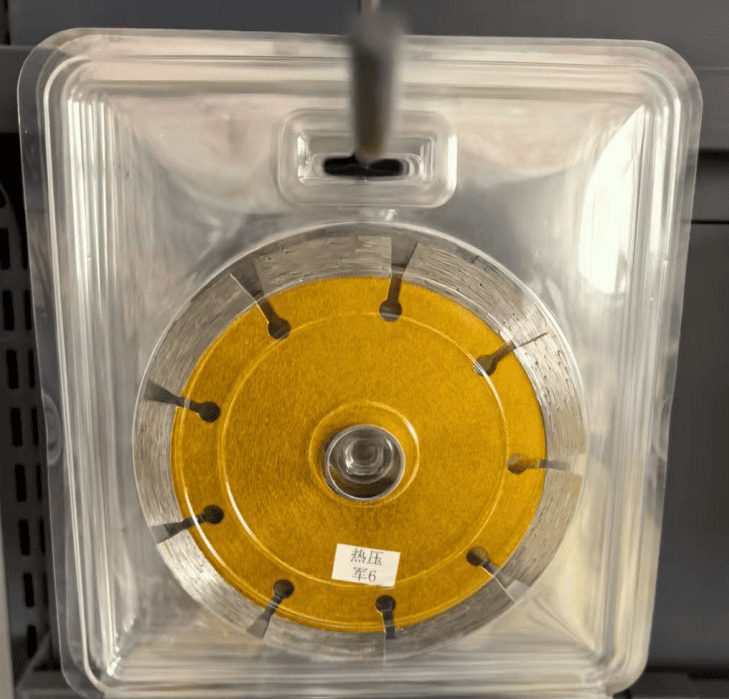

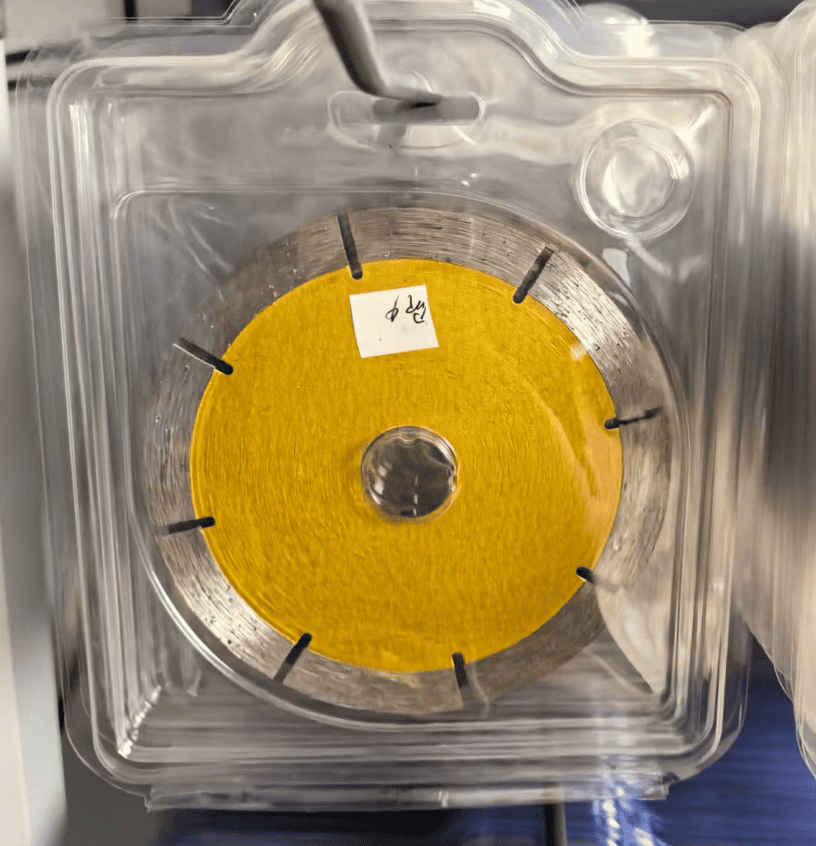

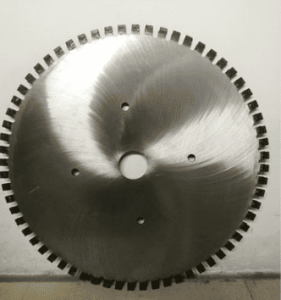

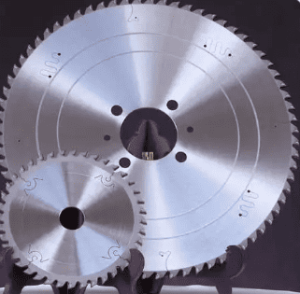

Diamond cutting blades, as high-hardness abrasives composed of diamond particles and metal powder sintered under high temperature and pressure, exhibit an exceptionally wide range of applications. These blades exhibit exceptional precision and durability when cutting metals like copper and copper alloys. However, in practical operations, selecting the appropriate blade specifications, shape, hardness, and even brand is crucial, depending on the material’s hardness, thickness, and geometry.

When using diamond cutting blades, several key precautions must be observed to ensure optimal performance and safety. First, a thorough inspection of both the cutting machine and the blade should be conducted before operation to confirm their integrity. Second, during cutting, the cutting direction must align with the blade’s rotation to prevent hazardous reverse cutting. Additionally, adequate lubrication is essential to avoid overheating and blade damage. After cutting, residues such as metal chips and cutting marks should be promptly cleaned to maintain the blade’s efficiency in subsequent uses. Lastly, operators must wear appropriate protective gear to safeguard against potential injuries. In summary, while diamond cutting blades excel in copper cutting, strict adherence to operational guidelines is necessary to achieve both high-quality results and safety.

Can Diamond Blades Be Used for Turning Soft Copper?

Diamond blades can indeed be employed for turning soft copper, though certain adjustments and considerations are required to ensure effectiveness.

Introduction to Diamond Blades

Diamond blades, also known as diamond cutting tools, are manufactured using high-quality industrial diamond micro-powder and various metal powders. Due to the extreme hardness and sharpness of diamond, these blades are widely utilized in cutting hard materials such as stone, ceramics, and glass. However, their application in softer materials like copper demands specific modifications.

Applicability of Diamond Blades in Soft Copper Turning

Soft copper, being a malleable metal, can be machined using diamond blades, but several factors must be taken into account:

- Blade Selection – Given the relatively low hardness of soft copper, a finer-grit diamond blade is preferable to prevent excessive material removal. Additionally, ensuring the blade is properly dressed (sharpened and conditioned) will enhance cutting performance.

- Parameter Optimization – Cutting parameters must be adjusted to match the properties of soft copper. Factors such as tool pressure, feed rate, and cutting depth should be carefully calibrated to maximize efficiency while minimizing wear.

- Lubrication – Due to the high friction generated during the cutting process, appropriate lubricants or coolants must be applied to reduce heat buildup, improve surface finish, and prolong blade life.

Conclusion

While diamond blades are capable of cutting soft copper, their effectiveness depends on proper blade selection, parameter adjustment, and lubrication. Operators must also prioritize safety measures to prevent accidents and tool damage. By following these guidelines, diamond blades can deliver precise and efficient results in soft copper turning applications.