Can you cut steel with a grinding wheel?

Grinding Wheels Be Used to Cut Steel?

Yes, grinding wheels can be used to cut steel, but it is essential to select a grinding wheel specifically designed for cutting steel and strictly follow safety precautions.

1. What Is a Grinding Wheel?

A grinding wheel is an abrasive tool used for grinding and cutting materials. It typically consists of three components:

- Abrasive grains (the cutting material)

- Bonding agent (holds the abrasive together)

- Pores (allow chip clearance and cooling)

Grinding wheels are widely used in processing metals, ceramics, glass, and other materials.

2. Can Grinding Wheels Cut Steel?

Yes, but standard grinding wheels are not specifically designed for cutting steel. Using the wrong type may cause wheel breakage or accidents. For steel cutting, choose a specialized steel-cutting grinding wheel, which has:

- Higher hardness and toughness

- Reinforced bonding materials

- Optimized abrasive composition

Additionally, always use a proper cutting machine and follow safety guidelines to ensure efficiency and safety.

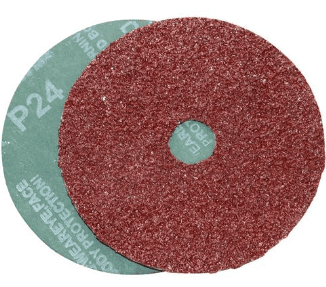

3. How to Choose the Right Grinding Wheel?

Consider the following factors:

- Material Compatibility – Select a wheel designed for steel cutting.

- Size – Larger wheels improve efficiency but must match the machine’s specifications.

- Grit Size – Coarser grit cuts faster but may leave a rougher finish; finer grit provides smoother cuts.

- Hardness – A harder wheel lasts longer but may generate more heat.

4. Safety Precautions for Cutting Steel with Grinding Wheels

- Wear PPE: Safety goggles, gloves, and a dust mask.

- Secure the Workpiece: Use clamps to prevent movement.

- Follow Operating Guidelines: Avoid overloading and prolonged use to prevent overheating.

- Inspect the Wheel: Replace if cracked or damaged.

- Clean Up After Use: Turn off the machine and store the wheel properly.

Conclusion

Grinding wheels can cut steel, but only with the correct type of wheel and strict adherence to safety procedures. Proper selection and usage are crucial for cutting quality and operator safety.

Stainless Steel Cutting Guide: Thermal vs. Grinding Wheel Cutting

Overview of Stainless Steel Cutting Methods

Stainless steel cutting methods fall into two categories:

- Thermal Cutting (e.g., plasma, laser) – Fast but may compromise edge quality.

- Cold Cutting (e.g., sawing, waterjet, grinding wheels) – More precise with cleaner edges.

Among cold-cutting methods, grinding wheel cutting stands out for its efficiency, precision, and smooth finish, making it ideal for industrial applications.

Advantages of Grinding Wheel Cutting

- High cutting speed

- Clean, burr-free edges

- Cost-effective for mass production

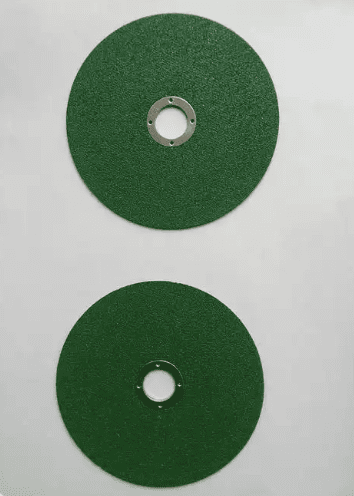

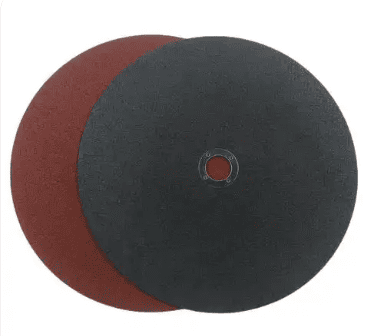

▲ Choosing the Right Grinding Wheel

Avoid rubber-bonded or fiber-reinforced wheels, as they may produce harmful dust. Instead, opt for resin-bonded, mesh-free grinding wheels for safer and cleaner cuts.

02 AUTOFOR Technology

▲ Recommended Grinding Wheels for Stainless Steel

AUTOFOR specializes in stainless steel cutting technology, offering dedicated grinding wheels for optimal performance.

▲ AUTOFOR Cutting System

Available in multiple sizes (e.g., 150×0.5-1.0×25.4/32, 180×0.5-1.0×25.4/32, 205×0.8-1.2×25.4/32), AUTOFOR wheels ensure:

- No burn marks

- Smooth, burr-free cuts

- Extended wheel life

For best results, pair with AUTOFOR cutting machines and coolant solutions for maximum efficiency.