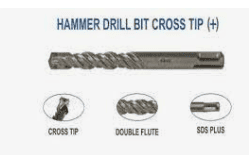

Do you need to grease a sDs hammer drill?

Do New Hammer Drills Need Oil?

Generally, new hammer drills do not require additional oiling, but regular maintenance should be performed based on usage and the manufacturer’s instructions.

Hammer drills are widely used in construction and renovation. A common question among new users is: “Does a brand-new hammer drill need oil?” Here’s a detailed explanation:

1. Do New Hammer Drills Need Oil?

- Factory Lubrication: New hammer drills are pre-lubricated during manufacturing, so no extra oil is needed initially.

- Long-Term Maintenance: Over time, internal lubrication degrades due to friction. Follow the user manual for scheduled maintenance, including:

- Cleaning dust/debris

- Replacing worn parts

- Inspecting power cords

- Adding specialized lubricant if needed

⚠️ Caution:

- Different brands/models have unique maintenance requirements—always consult the manual.

- Avoid disassembling or oiling randomly to prevent damage or safety risks.

2. Key Usage Tips

✔ Operate Correctly: Avoid excessive force or misuse.

✔ Keep It Clean: Regularly remove dust and debris.

✔ Store Properly: Keep in a dry, ventilated area to prevent moisture/heat damage.

✔ Replace Worn Parts: Change damaged drill bits or components promptly.

Why Does My New Hammer Drill Machine Overheat?

Common causes of rapid heating:

- Prolonged Use → Let it cool between sessions.

- Worn Parts (e.g., bits, gears) → Contact aftersale services for replacements.

- Poor Ventilation → Work in well-ventilated areas or use cooling aids.

Summary:

- No initial oiling required, but regular upkeep is essential.

- Prevent overheating by managing workload and environment.

- Always wear safety gear (goggles, gloves) and follow manuals.

What Oil Should Be Used in Hammer Drills?

Most modern hammer drills do not need oil—they feature self-lubricating systems. However:

Maintenance Best Practices:

- Clean Regularly: Use a brush/cloth to remove dust/metal shavings.

- Avoid Harsh Cleaners: They may corrode components.

- Check for Wear: Replace damaged bits or chucks immediately.

For Models Requiring Lubrication (e.g., Cordless Hammer Drills):

- Locate Oil Ports (typically on the side/top).

- Use a high-temperature grease (320°F+/160°C+ resistant) for:

- Gearbox (especially plastic gears)

- Chuck mechanism

- Impact mechanism (e.g., hammer blocks, drive shafts)

- Apply sparingly—excess grease attracts dirt.

Pro Tip:

- For heavy-duty use (e.g., concrete/stone), opt for premium grease to reduce wear.

How Often Should You Lubricate?

Frequency depends on:

🔹 Usage Intensity:

- 6 hours/day → Lubricate after each session.

- Occasional use → Extend intervals.

🔹 Workload: High-force tasks demand more frequent greasing.

🔹 Tool Condition: Noisy/slowed operation signals relubrication is due.

🔹 Grease Quality: High-grade grease lasts longer.

Final Advice:

- Store tools in a dry tool box—avoid overnight exposure to humidity.

- Refer to the manual for brand-specific guidelines.

By following these steps, your hammer drill will deliver peak performance and longevity!

Read more for hammer drill charging and packing.