Can you use regular drill bits on a MAG drill?

Can Magnetic Base Drills Use Ordinary Drill Bits?

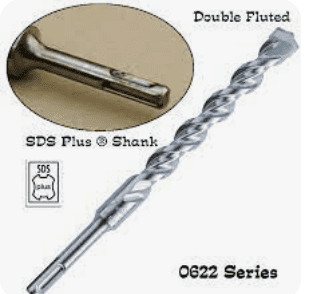

Multi-blade steel plate drills (also known as hollow drills or core drills) are high-efficiency drill bits with multi-blade annular cutting. They are available in diameters ranging from 12mm to 150mm and are primarily used for drilling steel structures, such as in steel construction projects, rail transit, bridges, ships, mechanical manufacturing, aerospace, and other hole-processing applications. Their drilling performance is significantly superior to traditional two-flute twist drills, offering high drilling efficiency and effortless cutting. When paired with a magnetic base drill, multi-blade steel plate drills enable multi-directional drilling on large workpieces, providing convenient and flexible operation while effectively reducing construction time. As a result, they have become the preferred tool for modern steel structure drilling and annular groove processing.

Multi-blade steel plate drills can be divided into two main categories based on material: high-speed steel (HSS) steel plate drills and carbide steel plate drills. HSS steel plate drills offer excellent stability and regrindability, making them the most widely used series. Carbide steel plate drills provide higher cutting speeds and can efficiently complete drilling tasks on complex materials.

Carbide Steel Plate Drills:

- Suitable for drilling complex materials and capable of higher cutting speeds.

- Equipped with high-performance carbide inserts specifically designed for steel plate drills, effectively reducing chipping and maintaining wear resistance.

- Multi-layer cutting edge geometry improves chip removal and minimizes cutting resistance.

- Available in various shank types (in addition to standard right-angle shanks) to suit different drills and drilling machines.

- Sizes range from Φ12mm to Φ150mm, with cutting depths of 35mm, 50mm, 75mm, and 100mm.

- Custom sizes from Φ150mm to Φ200mm and cutting depths up to 200mm can be ordered for special applications.

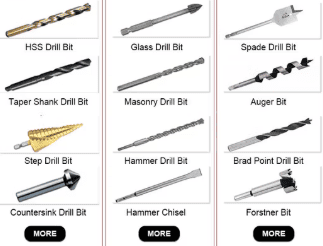

Magnetic base drills can be used with a variety of drill bits, including but not limited to:

- Ordinary Drill Bits: Suitable for drilling wood, steel, iron, and other materials.

- Center Drill Bits: Often used for pre-drilling positioning to ensure accuracy.

- Reamers: Also known as torque drills, they produce flat-bottomed holes with low surface roughness, ideal for deep or large-diameter holes.

- Twist Drill Bits: A common type of drill bit suitable for various materials.

- Core Drill Bits: Used to extract complete core samples from materials.

- Countersink Drill Bits: Suitable for applications requiring countersunk screws or rivets.

Additionally, specialized bits such as saw blade drill bits and grinding heads can be selected based on specific needs and workpiece materials.

When selecting a drill bit, factors such as workpiece material, drilling precision requirements, and the magnetic drill’s performance should be considered to ensure optimal results. Since different brands and models of magnetic drills may support varying types and specifications of drill bits, it is advisable to consult the drill’s user manual or the manufacturer for guidance.

Example Technical Parameters of a Magnetic Base Drill Bit:

- Bit Type: Twist drill bit

- Diameter Range: 1mm–100mm

- Material: HSS/Carbide

- Application: Suitable for drilling steel, iron, aluminum, and other materials.

Note: Specific technical parameters may vary depending on the bit type, brand, and model.

Can Drill Bits Be Used with Magnetic Drills?

Yes, drill bits can be mounted on magnetic drills.

1. What Is a Magnetic Drill?

A magnetic drill is a tool with a magnetic base used for installing bolts, screws, threaded pins, and other fasteners on metal surfaces. By generating electromagnetic force on its magnetic poles, it firmly adheres to metal workpieces, providing exceptional stability.

2. Can Drill Bits Be Used with Magnetic Drills?

Magnetic drills typically feature a chuck or arbor that allows drill bits or similar tools to be mounted. This ensures stability during drilling, enabling precise control over tool direction and speed for accurate hole placement.

3. How to Properly Use a Magnetic Drill and Drill Bit?

Using a magnetic drill and drill bit is straightforward:

- Place the magnetic drill on the metal surface to be worked on.

- Turn on the power to activate the magnetic adhesion.

- Install the drill bit into the drill’s chuck or arbor.

- Adjust the direction and speed, then begin drilling.

4. Precautions:

When using a magnetic drill and drill bit, observe the following:

- Ensure the magnetic drill has full contact with the metal surface to prevent movement or slippage during operation.

- Use cutting fluid to reduce wear and improve efficiency.

- Replace dull or worn drill bits promptly.

In summary, drill bits can indeed be used with magnetic drills, making them a versatile and practical tool for metalworking tasks. Always follow safety guidelines and best practices to ensure safe and effective operation.

How to Install a Drill Bit on a Magnetic Drill?

- After drilling, ensure the tool is fully secured without looseness or clamping issues.

- When using a magnetic base drill, ensure no iron chips are under the magnetic block, the surface is flat, and the machine is stable and fully adhered.

- Maintain continuous cooling throughout the drilling process to prevent tool collapse due to overheating.

- Start drilling with slow, steady feed. After cutting 1–2mm, increase the feed rate.

- Reduce cutting speed appropriately and maintain uniform feed during the process.

- The optimal cutting edge speed for carbide magnetic core drills (steel plate drills) should exceed 40 meters per minute. Due to carbide’s high hardness, avoid impact during storage, handling, and use.

- New hollow drill bits may experience minor edge chipping under intense initial use. For the first few holes, use slow feed rates to prevent edge damage.

- Once the blade naturally dulls, stable usage can be maintained, significantly extending tool life.

- If the machine overheats and stops during drilling:

- Turn off the power.

- Manually rotate the bit slightly in reverse to disengage it from the cutting area.

- Lift the motor, remove the bit, and inspect for abnormalities before resuming.

- If excessive chips wrap around the bit, remove them with a hook.

- Ensure the center pin and core ejector operate without significant wobble. Replace bent pins immediately.

- If the core doesn’t eject after drilling, tap it gently or use the tool’s small hole to assist removal.

- Handle cores carefully to avoid damaging the blades.

- If drilling resistance is low, retract the bit periodically to aid chip removal.

- Prioritize safety and protection throughout the drilling process.