Do SDS drill bits fit all drills?

All Drill Bits Are Universal – Matching the Right Bit to Your Power Tool

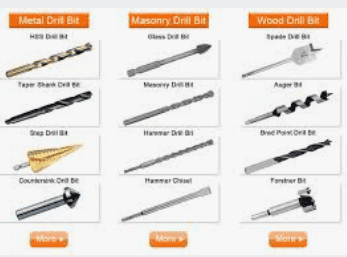

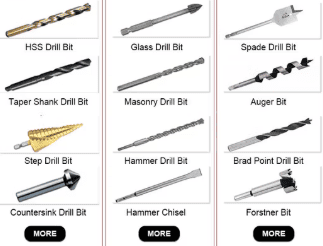

Before discussing whether drill bits are interchangeable, let’s first examine their different types and classifications.

1. Classification of Drill Bit Models

Common drill bit models include:

- Straight Shank Drill Bits

- Diameter: Typically 6mm

- Compatible with: Handheld electric drills

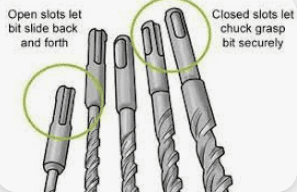

- SDS Drill Bits

- Types: SDS-Plus and SDS-Max

- Design: Spiral flutes with spring-loaded clamping mechanism

- Compatible with: SDS rotary hammers or SDS drills

- Square Shank Drill Bits

- Diameter: Usually under 10mm

- Compatible with: Demolition hammers or hammer drills

- Hex Shank Drill Bits

- Compatible with: Impact drills, pneumatic drills, and other specialized power tools

2. Are Different Drill Bit Models Interchangeable?

A common question when purchasing drill bits is: “Are all drill bit models universally compatible?” The answer is no. Different drill bit types are designed for specific power tools and should not be mixed.

For example:

- Straight shank bits only work with handheld electric drills.

- SDS bits are exclusively for SDS rotary hammers or SDS drills.

- Square shank bits are meant for demolition hammers or hammer drills.

Therefore, when buying drill bits, always check compatibility to avoid safety hazards.

Additionally, even within the same model category, different brands may have slight variations in design, leading to potential incompatibility. For best results, stick to the same brand for both the drill and bits to ensure a perfect fit.

3. Key Usage Considerations

When using drill bits, keep these safety and performance tips in mind:

- Monitor Bit Wear

- Excessively worn bits can break unexpectedly, posing a safety risk.

- Avoid Overuse on Hard Materials

- Drilling into overly hard surfaces (e.g., reinforced concrete, hardened steel) can accelerate wear, shorten bit lifespan, and even damage the drill motor.

- Adjust Speed & Torque Settings

- Before drilling, set the correct RPM and torque to ensure smooth penetration without jamming, overheating, or burning the material.

4. Conclusion

Drill bits are not universally interchangeable—each type is designed for specific power tools. When purchasing, always verify compatibility to ensure safe operation. During use, check for wear, avoid overly hard materials, and adjust drill settings for optimal performance and longevity.

By following these guidelines, you can maximize efficiency, safety, and tool lifespan.