Is a hammer drill an SDS drill?

What is the Official Terminology for Hammer Drill Bits?

1. Official Terminology for Hammer Drill Bits

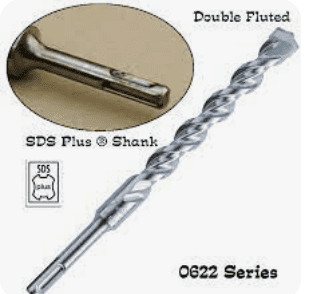

The official term for hammer drill bits is “rotary hammer drill bits”, also known as “SDS drill bits”. SDS stands for “Steck-Dreh-Sitz” (Insert-Twist-Stay) or “Slotted Drive System”, referring to their specialized shank design for secure attachment.

2. Features of Hammer Drill Bits

Hammer drill bits operate using a rotary hammering mechanism, allowing rapid penetration into materials for faster and more efficient drilling. Compared to conventional drill bits, they offer:

- High Efficiency: Rapid hammering action speeds up drilling progress.

- Durability: Made from special alloys and heat-treated to withstand high temperatures, pressure, and wear.

- Stability: The SDS connection system ensures a tight fit between the bit and drill, minimizing wobbling.

3. Applications of Hammer Drill Bits

Widely used in construction, manufacturing, and repair, these bits are suitable for drilling into:

- Concrete, stone, metal, and wood.

Common use cases include:

- Building Repairs: Drilling walls, floors, and ceilings for pipes, wiring, or drainage systems.

- Metalworking: Creating holes in metal plates for machining or assembly.

- Woodworking: Furniture making and carpentry tasks.

In summary, hammer drill bits are efficient, durable, and stable, making them essential for construction and industrial applications. Their official terms are rotary hammer drill bits or SDS drill bits.

Hammer Drill Bit Models & Size Specifications

Hammer drill bits are common power tool accessories used in construction, renovation, and home repairs. Their models and sizes vary to suit different tasks. Below are common types and dimensions to help users select the right bit.

1. Straight Shank Hammer Drill Bits

- Models:

- SDS-Plus: For light-duty work (e.g., small concrete holes).

- SDS-Max: For heavy-duty applications (e.g., deep drilling in reinforced concrete).

- Dimensions:

- SDS-Plus: Shank diameter 10mm, length 160mm.

- SDS-Max: Shank diameter 18mm, length 340mm.

2. Flat Shank Hammer Drill Bits

- Models:

- SDS-Top: Light-duty tasks (e.g., thin masonry).

- SDS-Quick: Heavy-duty drilling (e.g., thick stone or brick).

- Dimensions:

- SDS-Top: Shank width 20mm, length 100mm.

- SDS-Quick: Shank width 30mm, length 150mm.

3. Hex Shank Hammer Drill Bits

- Models:

- 6.35mm (1/4″): Light-duty use (e.g., wood or thin metal).

- 9.53mm (3/8″): Heavy-duty applications (e.g., thick steel beams).

- Dimensions:

- 6.35mm: Shank width 6.35mm, length 50mm.

- 9.53mm: Shank width 9.53mm, length 100mm.

Selection Tips:

- Match the bit to your material and workload (light/heavy duty).

- Always wear safety goggles and gloves during operation.

Hammer Drills vs. Rotary Hammers: Features & Usage Guide

1. Functions & Applications

- Hammer Drills: Combine rotation + hammering for drilling into hard materials (concrete, stone). Ideal for:

- Construction, renovation, geological surveys.

- Rotary Hammers: Add electropneumatic hammering for higher efficiency. Best for:

- Heavy-duty concrete drilling, demolition work.

2. Bit Types & Selection

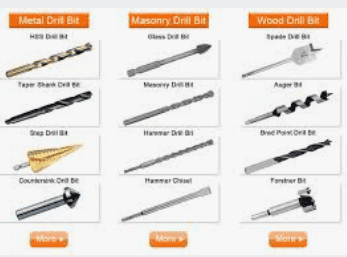

- Cylindrical Shank Bits: For soft materials (bricks, soft concrete).

- SDS-Plus/SDS-Max Bits: For hard materials (reinforced concrete, granite).

- Tri-Function Bits (New Trend): Combine drilling, hammering, and chiseling—versatile for mixed tasks.

3. Usage Instructions

- Hammer Drill Modes:

- Drill Mode: For metal/wood.

- Hammer Drill Mode: For masonry (cement, bricks).

- Rotary Hammer Modes:

- Hammer Drill Mode: Fast concrete penetration.

- Chisel Mode: For breaking tiles or light demolition.

Pro Tip: Choose bits based on hole diameter/depth and material hardness. For example:

- Use SDS-Plus for 6–12mm holes in concrete.

- Use SDS-Max for >12mm holes or rebar drilling.

By understanding these tools and bits, users can enhance efficiency and safety in construction and DIY projects.