What does HSS stand for on a drill bit?

High-Speed Steel (HSS) is a type of tool steel known for its high hardness, wear resistance, and heat resistance. It is also referred to as high-speed tool steel or锋钢 (feng gang) and commonly called white steel. HSS was developed in 1898 by F.W. Taylor and M. White in the United States.

HSS exhibits excellent processing properties, combining high strength with toughness, making it primarily suitable for manufacturing complex thin-edged and impact-resistant metal-cutting tools. It is also used to produce high-temperature bearings and cold extrusion molds, among other applications. In addition to HSS produced by smelting methods, powder metallurgy HSS emerged after the 1960s. The advantage of this method is that it avoids the carbide segregation caused by smelting, which can reduce mechanical properties and lead to heat treatment deformation.

Development History

The W18Cr4V HSS had poor thermoplasticity, which led to the development of W6Mo5Cr4V2 HSS to meet the requirements of twist drill hot-rolling processes. Additionally, W9Mo3Cr4V was introduced. These three types of HSS have similar cutting and mechanical properties and are referred to as general-purpose HSS.

By the mid-20th century, rapid advancements in science and technology and the emergence of various difficult-to-machine materials rendered general-purpose HSS inadequate. Consequently, high-performance HSS and powder metallurgy HSS were developed, significantly improving the performance of HSS tool materials.

Manufacturing Process

The heat treatment process for HSS is relatively complex, involving steps such as quenching and tempering. Due to its poor thermal conductivity, quenching is typically performed in two stages: preheating at 800–850°C (to avoid excessive thermal stress), followed by rapid heating to the quenching temperature of 1,190–1,290°C (varies by grade), and then cooling in oil, air, or gas. Salt bath furnaces are commonly used in factories, though vacuum furnaces are also widely employed.

After quenching, about 30% of the internal structure remains as retained austenite, which has not transformed into martensite, affecting the performance of the HSS. To transform the retained austenite and further enhance hardness and wear resistance, tempering is usually performed 2–3 times at 560°C, with each cycle lasting one hour.

Production Methods: HSS is typically produced using electric furnaces. Powder metallurgy methods have also been employed, resulting in extremely fine carbide particles uniformly distributed in the matrix, thereby improving service life.

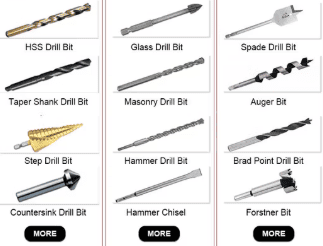

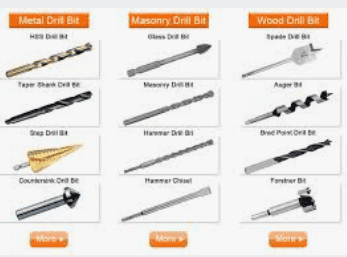

Applications: Used to manufacture various cutting tools, such as lathe tools, drill bits, hobs, mechanical saw blades, and high-demand molds.

Specifications and Composition

Specifications and Appearance

HSS is mainly available in round bars, square bars, and plates. The surface of the steel must be well-processed, free from visible cracks, folds, seams, or streaks. Cold-drawn steel surfaces should be clean, smooth, and free from inclusions or oxidation scales.

Chemical Composition

The chemical compositions of major steel grades under Chinese national standards and Japanese industrial standards are shown in Table 6-7-24.

Main Types

HSS is a complex steel type with a carbon content generally ranging from 0.70% to 1.65%. It contains a significant amount of alloying elements, totaling 10–25%. Based on the alloying elements, HSS can be classified into:

- Tungsten-series HSS (tungsten content: 9–18%).

- Tungsten-molybdenum-series HSS (tungsten: 5–12%, molybdenum: 2–6%).

- High-molybdenum-series HSS (tungsten: 0–2%, molybdenum: 5–10%).

- Vanadium HSS, further divided into standard vanadium content (1–2%) and high vanadium content (2.5–5%).

- Cobalt HSS (cobalt content: 5–10%).

HSS can also be categorized by application into general-purpose and special-purpose types.

- General-purpose HSS: Primarily used to manufacture cutting tools for materials with hardness ≤300 HB (e.g., drill bits, taps, saw blades) and precision tools (e.g., hobs, gear cutters, broaches). Common grades include W18Cr4V and W6Mo5Cr4V2.

- Special-purpose HSS: Includes cobalt HSS and ultra-hard HSS (hardness HRC 68–70), mainly used for cutting difficult-to-machine metals (e.g., high-temperature alloys, titanium alloys, and high-strength steels). Common grades include W12Cr4V5Co5 and W2Mo9Cr4VCo8.

General-Purpose Steel

- Grade: W18Cr4V (W18)

- Hardness (HRC): 62–65

- Flexural Strength (GPa): 3.0–3.4

- Impact Toughness (MJ/m²): 0.18–0.32

- Hardness at 600°C (HRC): 48.5

- Characteristics: Good strength, grindability, and moderate heat resistance; poor thermoplasticity.

- Main Uses: Versatile; widely used for drill bits, reamers, taps, milling cutters, gear tools, and broaches.

High-Performance Steel

- Grade: W6Mo5Cr4V2 (M2)

- Hardness (HRC): 63–66

- Flexural Strength (GPa): 3.5–4.0

- Impact Toughness (MJ/m²): 0.30–0.40

- Hardness at 600°C (HRC): 47–48

- Characteristics: High strength, good thermoplasticity; slightly inferior heat resistance and grindability compared to W18Cr4V; can be ground with standard alumina wheels.

- Main Uses: Suitable for hot-forming tools and tools with thin or impact-prone structures.

- Grade: W14Cr4VMnRE

- Hardness (HRC): 64–66

- Flexural Strength (GPa): ~4.0

- Impact Toughness (MJ/m²): ~0.31

- Hardness at 600°C (HRC): 50.5

- Main Uses: Comparable cutting performance to W18Cr4V; suitable for hot-rolled tools.

Key Properties

Also known as风钢 (feng gang) or锋钢 (feng gang), or white steel, HSS can harden even when cooled in air during quenching and remains sharp. It is a complex alloy steel containing carbide-forming elements such as tungsten, molybdenum, chromium, vanadium, and cobalt, with total alloy content reaching 10–25%. It maintains high hardness (HRC ≥60) even under high-speed cutting conditions (around 500°C). This is HSS’s most critical property—red hardness.

In contrast, carbon tool steel, after quenching and low-temperature tempering, exhibits high hardness at room temperature but rapidly loses hardness above 200°C. At 500°C, its hardness drops to levels similar to annealed states, rendering it useless for cutting metals. HSS overcomes this limitation, making it ideal for cutting tools.

HSS is typically not tested for tensile strength but is evaluated based on metallographic and hardness tests.

- Tungsten- and molybdenum-series HSS achieve Rockwell hardness ≥63 after proper heat treatment, while cobalt-series HSS reaches ≥65.

- Acid-etched macrostructure should show no visible shrinkage cavities, folds, or severe porosity (generally ≤1 grade).

Metallographic Inspection: Focuses on decarburization, microstructure, and carbide uniformity.

- HSS should not exhibit significant decarburization. The microstructure must not show fishbone-like eutectic ledeburite.

- Carbide uniformity greatly impacts quality. Levels should generally be ≤3, depending on the application.

- Red hardness—the ability to resist softening at high temperatures—is crucial for HSS cutting tools.

A common red hardness test involves heating the steel to 580–650°C for 1 hour, cooling, and repeating four times before measuring hardness.

- HSS quenching temperatures are near the steel’s melting point (e.g., 1,210–1,240°C for tungsten-series, 1,180–1,210°C for high-molybdenum-series).

- Tempering is typically performed 3 times at 540–560°C.

- Surface treatments like low-temperature cyaniding, nitriding, or sulfur-nitrogen co-treatment can further enhance tool life.

Packaging and Inspection

Packaging: Bundled with wire, labeled with furnace number and specifications. Cold-rolled steel is coated with rust-proof oil and wrapped in moisture-proof paper; bright steel is boxed.

Inspection: Carbide uniformity assessment depends on etching time. Over-etching can falsely improve apparent uniformity, leading to misclassification. Proper etching is critical to avoid this.

Detailed Explanation of HSS Drill Bit Materials and Standard Specifications

1. HSS Drill Bit Materials

HSS (High-Speed Steel) is a tool steel with high hardness, wear resistance, and heat resistance. It is ideal for drill bits, offering excellent cutting performance and durability, especially for metal drilling. HSS drill bits are widely used in manufacturing, including benchwork and electrical work.

2. Standard Specifications for Drill Bits

Common specifications include M3, M4, M5, and M6, categorized by dimensions such as total length, shank diameter, blade length, minor diameter, and major diameter. For example:

- M3: Total length 65mm, shank diameter 6.4mm, blade length 35mm, minor diameter 3.4mm, major diameter 6.4mm.

- M6: Total length 90mm, shank diameter 12.0mm, blade length 53mm, minor diameter 6.6mm, major diameter 12.5mm.

3. Labeling Methods

Drill bit labels include the model, dimensions, and special treatments (e.g., nitrided black drills or fully ground white HSS drills). Selecting the right drill bit depends on the application, material, and machining conditions.

What is HSS-Co Drill Bit Material?

HSS stands for High-Speed Steel, and Co stands for cobalt. HSS-Co drill bits are made from cobalt-enriched HSS, typically containing 3%, 5%, or 8% cobalt—the higher the cobalt content, the better the performance.

Cobalt (Co): A silvery-white ferromagnetic metal with a slight pink tint. It is hard, brittle, and loses magnetism when heated to 1,150°C. Cobalt powder can spontaneously ignite in air, forming cobalt oxide. It is essential for heat-resistant, hard, corrosion-resistant, and magnetic alloys.

German Becker added 3–5% cobalt to steel, improving its red hardness.

- Special-Purpose HSS: Includes cobalt HSS and ultra-hard HSS (HRC 68–70), used for cutting difficult metals (e.g., high-temperature alloys, titanium alloys). Common grades: W12Cr4V5Co5, W2Mo9Cr4VCo8.