What is the difference between abrasive wheel and grinding wheel?

A grinding wheel, also known as an abrasive wheel, is a wheel made of abrasive particles bound together by various substances, such as rubber, shellac or silicate. They are used by a variety of industries but, if not used safely, have the potential to cause serious injury.

Abrasive Grinding and Cutting Wheels: Choosing the Right Tool for the Job

Grinding and cutting wheels come in various sizes and compositions, each engineered with specialized abrasive compounds to deliver optimal material removal or cutting performance for specific metals. While a traditional saw relies on teeth along its edge, a grinding or cutting wheel features abrasive grains distributed throughout its surface, allowing it to both grind and cut efficiently.

Understanding the Grinding and Cutting Process

Abrasive machining—the technical term for grinding and cutting—involves removing metal in fine chips using irregularly shaped abrasive particles that are harder than the workpiece. These wheels consist of thousands of abrasive grains bonded together, with each grain acting as a microscopic cutting edge. As grains wear down, they fracture, exposing fresh cutting surfaces to maintain efficiency.

Types of Abrasives in Grinding and Cutting Wheels

Most modern grinding and cutting wheels use manufactured abrasives, as they offer superior performance compared to natural abrasives (with the exception of diamonds, which are increasingly synthetic). The choice of abrasive depends on the workpiece material, ensuring the wheel stays sharp and fractures appropriately to maintain cutting efficiency.

Key abrasives include:

- Aluminum Oxide – The most common abrasive, ideal for carbon steel, alloy steel, high-speed steel, wrought iron, and non-ferrous metals like bronze. Different formulations are tailored for specific grinding tasks.

- Zirconia Alumina – A durable blend of aluminum oxide and zirconium oxide, excellent for rough grinding and cut-off operations on steel and steel alloys.

- Silicon Carbide – Best for grinding gray iron, brass, aluminum, stone, rubber, and other non-ferrous materials.

- Ceramic Aluminum Oxide – A high-performance abrasive with controlled fracturing, designed for precision grinding of hard-to-machine steels and alloys.

Selecting the Right Wheel

Choosing the correct grinding or cutting wheel depends on several factors:

✔ Material being worked (steel, aluminum, concrete, etc.)

✔ Amount of material removal required

✔ Wheel speed and grinding contact area

✔ Grinding intensity and machine horsepower

Matching these factors with the appropriate abrasive ensures optimal performance and longevity.

Grinding Discs vs. Grinding Wheels: Key Differences

While both tools serve grinding purposes, they differ in design, application, and performance.

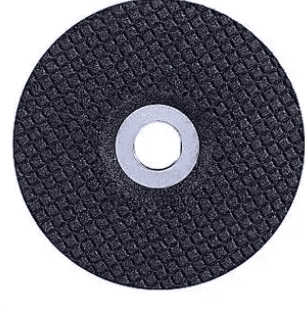

Grinding Discs

- Design: Thin, circular discs used with angle grinders or handheld tools.

- Materials: Aluminum oxide, silicon carbide, or zirconia alumina, often reinforced with fiberglass.

- Applications: Light to medium grinding, shaping, sanding, and finishing.

- Sizes: Typically 4″ to 9″ in diameter.

- Speed: Operate at higher RPMs for fast material removal.

- Cost: More affordable for small-scale jobs.

Grinding Wheels

- Design: Thicker, larger wheels for bench grinders and stationary machines.

- Materials: Aluminum oxide, silicon carbide, or diamond.

- Applications: Heavy-duty grinding, stock removal, and precision work on hard metals or concrete.

- Sizes: Range from 6″ to 12″ in diameter.

- Speed: Run at lower RPMs to prevent overheating.

- Cost: Higher initial investment but longer lifespan for demanding tasks.

Choosing the Right Tool

- For precision finishing or small projects → Grinding Discs

- For heavy-duty material removal → Grinding Wheels

By understanding these differences, you can select the best abrasive tool for your specific needs, ensuring efficiency, safety, and superior results.

Need help choosing the right abrasive solution? Let us guide you to the perfect grinding or cutting wheel for your application!