Is cutting wheel and grinding wheel same?

Grinding Wheels vs Cutting Discs: Are They the Same Tool?

Grinding Wheels and Cutting Discs: Not the Same Tool

Grinding wheels and cutting discs are not the same tool. They differ in application, cutting principles, and performance.

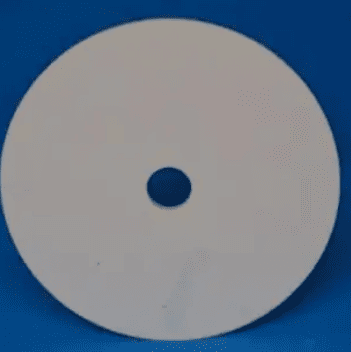

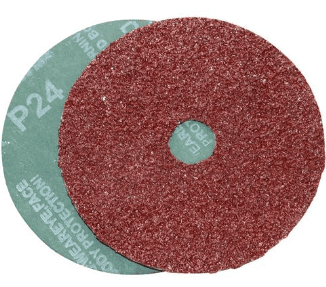

1. Grinding Wheels

A grinding wheel is an abrasive tool primarily used for grinding and cutting metal surfaces. Its main components are abrasive grains and bonding agents. When in use, the rotating grinding wheel generates high friction heat, enabling metal grinding or cutting. Grinding wheels are highly durable and deliver excellent cutting performance but wear out faster, requiring frequent replacement.

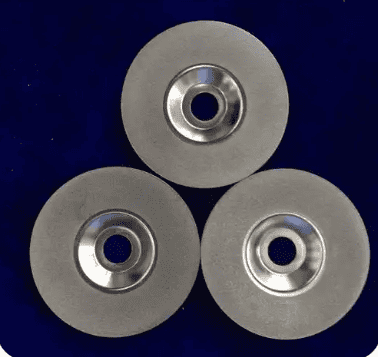

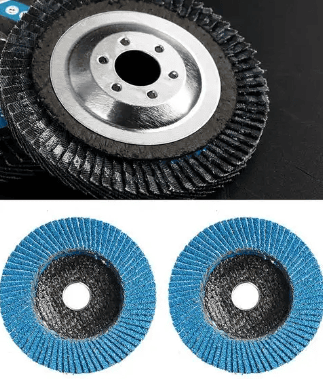

2. Cutting Discs

A cutting disc is also an abrasive tool, mainly used for cutting metal and non-metal materials. Its composition includes abrasives and bonding agents. During operation, the friction heat generated between the abrasive and the material facilitates cutting. Compared to grinding wheels, cutting discs are less rigid but offer greater toughness, finer cutting precision, and a longer lifespan.

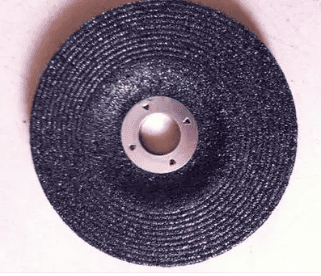

3. Key Differences Between Grinding Wheels and Cutting Discs

Grinding wheels and cutting discs differ in application, cutting mechanisms, and results:

- Application: Grinding wheels are for metal grinding and cutting, while cutting discs work on both metal and non-metal materials.

- Performance: Grinding wheels are harder and cut more aggressively but wear faster. Cutting discs are tougher, provide smoother cuts, and last longer.

In summary, although both are abrasive tools, grinding wheels and cutting discs have distinct differences in function and performance, making them non-interchangeable. The right tool should be chosen based on the specific task—whether grinding, cutting, or polishing.

Additional Features:

- Grinding Wheels: Can cut, grind, and polish, available in various shapes.

- Cutting Discs: Designed solely for cutting, categorized into resin cutting discs, diamond cutting discs, etc.

In-Depth Look

Grinding Wheels:

A primary tool in abrasive machining, grinding wheels are porous structures made of abrasives and bonding agents pressed, dried, and sintered. Their properties—determined by abrasive type, grit size, bond material, hardness, structure, and shape—significantly impact grinding quality, efficiency, and cost-effectiveness.

Cutting Discs:

A subtype of grinding wheels, cutting discs are thin sheets made of abrasives and resin bonds, designed for cutting steel, stainless steel, and non-metals. Common types include resin-bonded and diamond cutting discs.

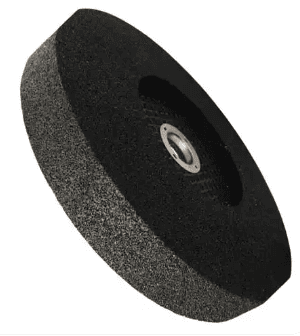

Professional Manufacturing

As a leading grinding wheel manufacturer, we provides high-quality products with various specifications, models, and competitive pricing. With advanced production and testing equipment, we develop custom grinding solutions for specialized applications.

Cutting Disc Production Processes:

- Cold Pressing: Uses liquid phenolic resin, furfural, or cresol as wetting agents.

- Semi-Hot Pressing: Operates at 50–65°C, enhancing resin flow for better molding under moderate pressure—ideal for automated production.

- Hot Pressing: Employs dry mixing or minimal furfural wetting for uniform abrasive-resin blending.

For premium grinding wheels and cutting discs, trust us for durability, precision, and performance.