Are all abrasive wheels used for cutting?

Not All Grinding Wheels Are Designed for Cutting

Grinding wheels are primarily intended for grinding operations, not cutting. While some grinding wheels can be used for cutting materials like tiles, this is not their main function.

Classification and Uses of Grinding Wheels

- Grinding Wheels

- Designed for surface grinding, not cutting or fine polishing.

- Require specialized abrasives and tools for optimal performance.

- Cutting Wheels (Cut-Off Wheels)

- Specifically engineered for cutting operations.

- Thinner than grinding wheels, with slight grinding capabilities.

- Resin & Diamond Cutting Wheels

- Used for cutting steel, stainless steel, and non-metallic materials.

- Offer high tensile, impact, and bending resistance.

Key Characteristics & Safety Guidelines

- Quality Inspection: Always check for cracks or defects before use. Replace damaged wheels immediately.

- Operational Safety:

- Never allow two operators to use the same machine simultaneously.

- Avoid excessive pressure to prevent wheel breakage.

Can Grinding Wheels Be Used for Cutting?

Yes, but with limitations.

1. Structure & Features of Grinding Wheels

- Composed of bonded abrasive grains (e.g., silicon carbide, aluminum oxide, diamond).

- Excel in grinding efficiency, longevity, and surface finish.

- Not all types are suitable for cutting.

2. Cutting Applications

- Metal Cutting: Uses aluminum oxide or silicon carbide wheels.

- Concrete/Stone Cutting: Requires diamond-embedded wheels.

- Material and thickness dictate wheel selection.

3. Critical Precautions

- Match the wheel to the material (e.g., diamond for stone, aluminum oxide for steel).

- Inspect for damage before installation.

- Maintain stability and angle during cuts to avoid shattering.

- Wear PPE (goggles, gloves) to protect against heat/debris.

Conclusion: Grinding wheels can cut, but prioritize safety and proper selection.

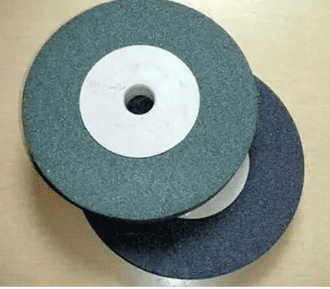

Types & Applications of Grinding Wheels

Widely used in industrial production, grinding wheels fall into three main categories:

- Ceramic Grinding Wheels

- High heat resistance, efficient grinding, and superior polishing.

- Delivers smooth, uniform finishes.

- Cutting Wheels

- Ultra-thin for slicing metal, ceramic, marble, asphalt, and glass.

- Grinding/Polishing Wheels

- For shaping, deburring, rust removal, and edge finishing.

Selection Criteria

- Abrasive Type:

- Conventional: Brown/aluminum oxide (tough, cost-effective for rough grinding).

- Premium: White aluminum oxide (harder, for precision grinding of hardened steel).

- Silicon Carbide: Black (brittle, ideal for cast iron/copper) or green (for carbide/ceramics).

- Grit Size:

- Coarse (36#–46#): Heavy material removal.

- Fine (60#–100#): Finishing and tool sharpening.

- Bond Type:

- Vitrified (Ceramic): Heat-resistant, rigid, for precision grinding (max 35 m/s).

- Resin: Flexible, high-speed (>50 m/s), ideal for rough grinding/cutting.

Final Note: Always consider wheel dimensions and RPM compatibility with your tool.