What are the three types of grinding wheels?

Grinding wheels are mainly divided into three types: ceramic grinding wheels, resin grinding wheels, and rubber grinding wheels. These classifications are based on differences in their bonding agents.

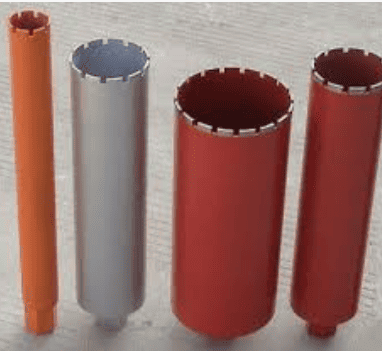

Ceramic Grinding Wheels

Ceramic grinding wheels use ceramic as the bonding agent, offering high hardness and strength. They are suitable for high-speed grinding and heavy-load grinding operations. With excellent wear resistance, they are ideal for processing high-hardness materials such as cast iron and cemented carbide.

Resin Grinding Wheels

Resin grinding wheels use resin as the bonding agent, providing good elasticity. They are suitable for precision grinding and surface finishing. Due to their lower grinding force, they are often used for thin-walled parts and precision components.

Rubber Grinding Wheels

Rubber grinding wheels use rubber as the bonding agent, offering good elasticity and vibration-damping properties. They are suitable for processing fragile or soft materials, such as wood and leather. With minimal grinding force, they help preserve the surface finish of workpieces.

Classification of Grinding Wheels by Shape and Application

As an essential tool in mechanical processing, grinding wheels are widely used in grinding, cutting, and other operations. Based on their shape and purpose, grinding wheels can be categorized into the following three main types:

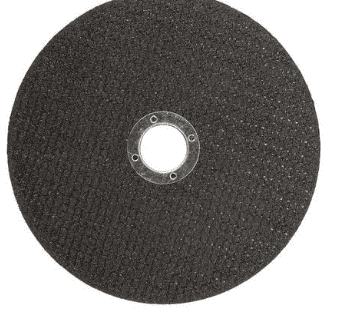

1. Flat Grinding Wheels (Flat Wheel)

Flat grinding wheels are the most common type, characterized by flat surfaces on both sides without any taper. These wheels are typically used for grinding flat or cylindrical surfaces. Due to their simple structure and ease of manufacturing, they are widely applied in various mechanical processing fields.

Selection Considerations:

- Pay attention to grit size, hardness, and bonding agent to ensure optimal grinding performance and longevity.

- Choose different wheel materials based on the workpiece material for the best grinding results.

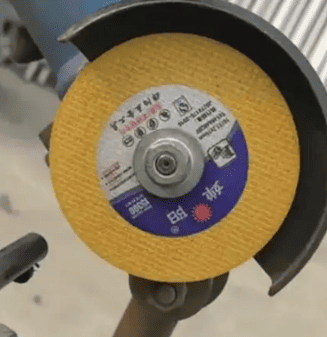

2. Single-Bevel Grinding Wheels (Single-Bevel Wheel)

Single-bevel grinding wheels feature one flat side and one beveled side. They are commonly used for grinding surfaces with various angles and complex shapes. Their flexible design makes them advantageous for grinding intricate workpieces.

Selection Considerations:

- In addition to standard parameters (grit size, hardness), the angle of the bevel must be carefully selected to ensure proper contact with the workpiece surface.

3. Double-Bevel Grinding Wheels (Double-Bevel Wheel)

As the name suggests, double-bevel grinding wheels have beveled edges on both sides. They are primarily used for grinding more complex shapes and angles, especially when grinding is required in two directions simultaneously.

Selection Considerations:

- Besides standard parameters, the angles of both bevels must be precisely measured to ensure compatibility with the workpiece.

- Due to their more complex manufacturing process, extra care is needed during use and maintenance to prevent damage and extend service life.

Conclusion

Grinding wheels can be classified into flat, single-bevel, and double-bevel wheels based on their shape and application. When selecting and using grinding wheels, it is crucial to consider specific processing needs and workpiece characteristics to achieve optimal grinding efficiency and finish quality. Additionally, proper usage and maintenance are key to ensuring machining accuracy and prolonging wheel lifespan.