What’s the point of cutting tires?

The Meaning and Role of Tire Cut Resistance

1. The Significance of Tire Cut Resistance

Tires are a critical component of vehicles such as cars and motorcycles, serving to absorb shocks, cushion impacts, and provide traction. During use, tires encounter various road conditions and environmental hazards—such as rocks, sharp objects, and glass shards—that can cause cuts, abrasions, and wear. Therefore, cut resistance is a vital feature in tire performance.

Cut-resistant tires not only extend service life and reduce replacement and maintenance costs but also enhance driving safety. High-performance and industrial tires often incorporate cut-resistant designs to withstand heavy loads, high speeds, and harsh terrains.

2. How Tire Cut Resistance Works

Achieving cut resistance involves multiple factors:

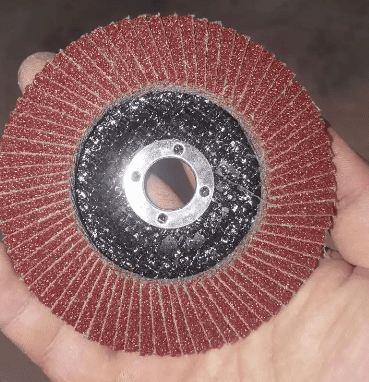

- Material Selection

- The tread and sidewall compounds, often made from high-performance polymers or reinforced rubber, help mitigate impact and shear forces.

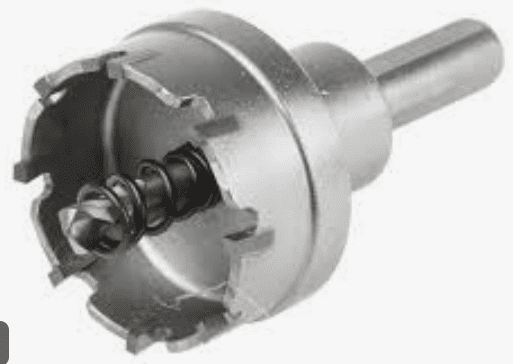

- Structural Design

- Key technologies include steel belts, polyester cord reinforcement, and cut-resistant tread patterns to enhance durability.

- Manufacturing Process

- Precise control of pressure and temperature during production ensures material integrity and performance.

3. Key Tips for Maximizing Cut Resistance

- Regular Maintenance – Inspect tires for cuts, cracks, and wear; replace damaged tires promptly.

- Optimal Tire Pressure – Proper inflation improves cut resistance but should not exceed the rated limit.

- Avoid Road Hazards – Steer clear of potholes and sharp debris to minimize impact damage.

- Drive Smoothly – Reduce sudden acceleration, braking, and sharp turns to prevent excessive wear.

In summary, cut resistance is crucial for tire longevity and safety. When purchasing tires, prioritize models with proven cut-resistant technology.

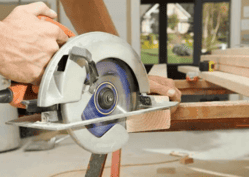

What Parts of a Tire Does a Tire Cutter Machine Cut?

A tire cutter machine is primarily used for cutting:

- Tread – Separating tread from the tire body helps analyze wear patterns and tread design efficiency.

- Sidewall – Cutting sidewalls reveals structural integrity, potential cracks, and delamination risks.

- Bead – Inspecting bead wires and rubber bonding ensures proper wheel mounting and stability.

These cuts aid in tire research, quality control, and repair, improving overall safety and performance.

The Importance of Waste Tire Rubber Cutting Machines

With rising global vehicle numbers, waste tire disposal has become an urgent environmental challenge. Traditional methods like landfilling and incineration waste resources and pollute ecosystems.

Waste tire rubber cutting machines offer a sustainable solution by:

- Shredding tires into manageable pieces for recycling into rubber mulch, asphalt additives, or fuel.

- Reducing storage/transport costs by compacting waste volume.

- Minimizing pollution compared to burning or dumping.

Challenges include:

- Noise/vibration during operation (requiring safety measures).

- Varied tire compositions demanding specialized cutting equipment.

Why Do Tires Get Sidewall Cuts? & Why Are Tires Buffed?

New tires may show sidewall cuts due to recycling processes (e.g., bead removal, shredding). Key considerations:

- If cords are intact, short-term urban use may be possible, but replacement is ideal.

- Exposed cords demand immediate replacement—sidewall damage cannot be safely repaired due to constant flexing.

To prevent sidewall damage:

- Maintain correct tire pressure.

- Avoid curb impacts.

- Remove embedded debris (e.g., stones).

- Drive centrally to avoid uneven wear.

- Ensure proper wheel alignment.

By adopting these habits, you extend tire life and enhance safety.