How does a cutting wheel work?

Working Principle of Cutting Discs

The working principle of cutting discs primarily relies on their material composition and design characteristics. Cutting discs are typically made of abrasive grains and bonding agents, with common abrasives including diamond and silicon carbide. These materials possess extreme hardness, enabling them to effectively grind and remove the material being cut. When the cutting disc rotates at high speed, the abrasive particles on its edge come into contact with the material, gradually wearing it away through grinding action to form a cut.

Working Principles of Different Types of Cutting Discs

- Diamond Cutting Discs

- Sintered Diamond Cutting Discs: Manufactured through cold or hot pressing.

- Welded Diamond Cutting Discs: Diamond segments are bonded to the core via high-frequency or laser welding.

- Diamond, being the hardest known material, efficiently grinds and cuts through tough workpieces.

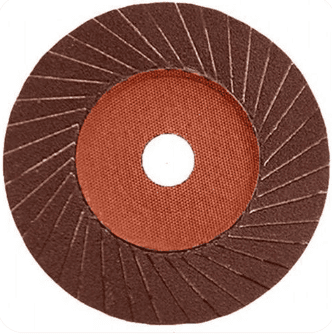

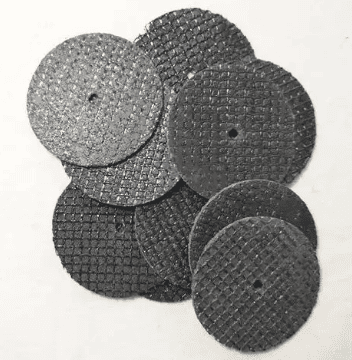

- Resin-Bonded Cutting Discs

- Use resin as a bonding agent, often reinforced with fiberglass mesh.

- Ideal for difficult-to-cut materials like alloy steel and stainless steel.

- Can be used in both dry and wet cutting modes for improved precision and efficiency.

Applications of Cutting Discs

Cutting discs are widely used for slicing various materials, including metals, stone, concrete, ceramics, and other hard, brittle substances.

- Diamond cutting discs are commonly used for stone, concrete, and precast panels.

- Resin-bonded cutting discs excel in cutting alloy steel and stainless steel.

- Diamond cutting discs are also used in road sawing, where their orderly arranged diamond particles enhance cutting efficiency and stability.

Cutting Discs vs. Grinding Discs

A cutting disc is essentially a metal abrasion tool composed of numerous small abrasive grains. At high rotational speeds, it efficiently grinds hard materials by gradually wearing away surface particles until separation occurs.

- Grinding discs work by friction, smoothing out oxidation layers, rust, and surface imperfections to create a polished finish.

- Cutting discs, on the other hand, use a high-speed rotating blade to make fast, clean cuts.

In essence:

- Grinding discs abrade the material.

- Cutting discs slice through it.

This fundamental difference determines their respective applications in metalworking, construction, and fabrication.