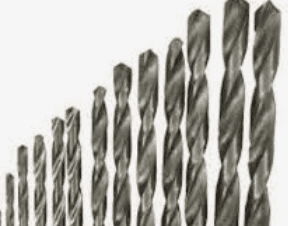

What does SDs mean on a drill bit?

SDS Drill Bits, also known as SDS-Plus drill bits, are consumables designed for use with rotary hammers. The term “SDS” originates from the German phrase “Stecken-Drehen-Sichern,” meaning “Insert-Twist-Lock.” This system is engineered for quick and secure bit changes.

The most distinctive feature of an SDS drill bit is its shank, which has a cylindrical design with two grooves and two indentations. This design ensures a firm grip in the chuck without excessive tightening while allowing the bit to slide freely like a piston during operation, enhancing efficiency.

The two grooves in SDS bits optimize high-speed hammering performance, making drilling faster and more effective. These bits are particularly suited for drilling into hard materials such as concrete, stone, and masonry. Thanks to their cylindrical shank design, SDS bits offer high concentricity and minimal wobble, ensuring precise drilling.

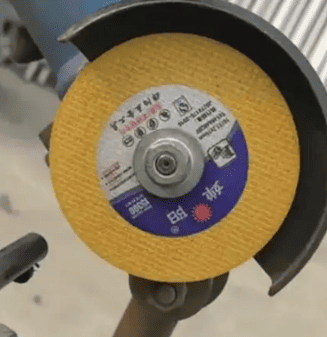

2. The Usage and Advantages of Ebor Electric Drill SDS Chuck Adapters

The Ebor Electric Drill SDS Chuck Adapter, when paired with SDS drill bits, significantly improves work efficiency and convenience. Its ingenious design allows for quick insertion and locking of SDS bits, eliminating the need for tedious tightening procedures.

During operation, the Ebor SDS chuck adapter ensures a secure fit between the bit and the chuck, maintaining stability even under high-intensity workloads and reducing the risk of bit loosening. Additionally, its user-friendly operation enables faster bit changes, minimizing downtime and boosting productivity.

3. Applications of SDS Drill Bits and Ebor SDS Chuck Adapters

SDS drill bits and Ebor SDS chuck adapters are widely used in construction sites, home renovations, and any scenario requiring drilling operations. They are particularly effective for drilling into hard materials like concrete and stone, making them a top choice for professional contractors and DIY enthusiasts.

In summary, the unique design and superior performance of SDS drill bits, combined with the Ebor SDS chuck adapter, enhance drilling efficiency, safety, and precision. Whether for professionals or hobbyists, this toolset simplifies drilling tasks with ease.

Understanding Drill Bit Model Numbers

1. Basic Structure of Drill Bit Model Numbers

Drill bit model numbers typically consist of letters and numbers, each indicating specific characteristics. Common models include SDS, HSS, and CARB, among others.

For example:

- SDS stands for “System, Direct, Synthetic.”

- HSS stands for “High-Speed Steel.”

- CARB refers to “Carbide-tipped.”

2. Meaning Behind Drill Bit Models

SDS Drill Bits

- Model format: SDS-Plus 5, SDS-Max 10, etc.

- “Plus” and “Max” indicate different SDS designs.

- The number represents the diameter size.

- Advantages: Long service life, high efficiency, reduced operator fatigue.

HSS Drill Bits (High-Speed Steel)

- Model format: HSS-R 5.5, HSS-Co 8.5, etc.

- “R” and “Co” denote coating types (e.g., cobalt-enhanced).

- The number indicates the diameter.

- Best for: Steel, iron alloys, cast iron, and other high-hardness metals.

CARB Drill Bits (Carbide-Tipped)

- Model format: CARB-K 5.5, CARB-T 6.5, etc.

- Letters indicate bit shape, while numbers denote diameter.

- Best for: Forged steel, alloy steel, cast iron—offering high wear resistance and hardness.

3. How to Choose the Right Drill Bit

- Based on Material

- Match the bit type to the workpiece material (e.g., SDS for masonry, HSS for metal).

- Based on Drilling Operation

- Consider the drilling method (e.g., plunge cutting, angled drilling, tapping).

- Based on Precision Requirements

- Select bits with appropriate tolerance, coating, and geometry for optimal results.

Conclusion

Drill bit model numbers reflect key specifications such as diameter, shank type, and flute length. Choosing the right bit enhances both efficiency and drilling quality.

How to Select the Right Drill Bit?

Choosing the correct drill bit depends primarily on the material being drilled. Each material has unique hardness and mechanical properties, necessitating different bit types.

Key Selection Criteria:

- Material: High-speed steel (HSS) or tungsten carbide (CARB).

- Mounting Type: Compatible with the drilling machine.

- Diameter: Matches the required hole size.

- Bit Type: Twist, step, reamer, center, conical, or insert-style.

- Coating: Enhances durability (e.g., titanium, cobalt).

- Point Angle: Affects penetration and chip clearance.

- Length: Short or long, depending on depth requirements.

Solid vs. Insert Drill Bits

- Insert Bits: Ideal for large-diameter holes, commonly used in machining centers.

- Advantages: Higher speed capability, cost-effective (replaceable inserts), multiple cutting edges.

- Solid Bits: More rigid, suitable for small diameters and tight tolerances.

- Advantages: Easily resharpened when worn.

Which Bit for Which Material?

Here are the most commonly used drill bits:

- Wood: Standard twist bits for softwood, hardwood, plywood, etc.

- Metal: HSS or cobalt bits (insert bits for machine tools).

- Masonry: Carbide-tipped SDS or hammer drill bits.

- Tile & Glass: Spear-point bits (use at low speeds).

By considering these factors, you can select the optimal drill bit for your project, ensuring efficiency, precision, and longevity

One Comment