What are Abrasive wheels?

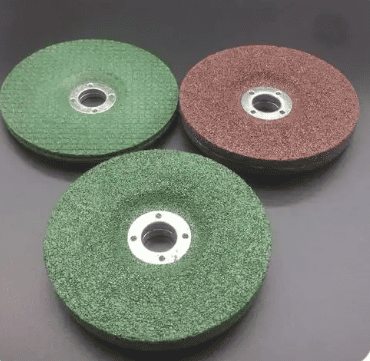

Abrasives are tools used for grinding, grinding and polishing. Most of the abrasives are artificial abrasives made of abrasives and binders, and also natural abrasives directly processed from natural minerals and rocks. In addition to being widely used in machinery manufacturing and other metal processing industries, abrasive tools are also used in grain processing, paper industry and the processing of non-metallic materials such as ceramics, glass, stone, plastics, rubber and wood.

Abrasive structure can be divided into three categories: tight, medium and loose. Each category can be further subdivided, etc., with the organization number to distinguish. The larger the abrasive structure number, the smaller the percentage of the volume of the abrasive in the abrasive, the wider the gap between the abrasive particles, indicating the looser the organization. Conversely, a smaller organization number indicates a tighter organization. The grinder with the looser structure is not easy to passivate when used, and the heat is less during the grinding process, which can reduce the heat deformation and burn of the workpiece. The abrasive particles of the tighter structure are not easy to fall off, which is conducive to maintaining the geometric shape of the abrasive tool. The organization of abrasive tools is only controlled according to the formula of abrasive tools at the time of manufacturing, and is generally not measured. Superhard abrasive consolidation abrasives are mainly composed of diamond, cubic boron nitride and other bonded abrasives. Due to the high price of diamond and cubic boron nitride and good wear resistance, the consolidated abrasives made with them are different from ordinary abrasive consolidated abrasives, in addition to the superhard abrasive layer, there are transition layers and matrix. The superhard abrasive layer is the part that plays the cutting role and is composed of the superhard abrasive and the binder. The substrate acts as a support in grinding and is composed of materials such as metal, bakelite or ceramics. The transition layer is used to connect the matrix to the superhard abrasive layer and is composed of a binder, sometimes omitted. Commonly used bonding agents are resin, metal, electroplated metal and ceramics. The manufacturing process of consolidated abrasive tools includes: material distribution, mixing, molding, heat treatment, processing and inspection. Depending on the binder, the manufacturing process is not the same. The ceramic binder abrasives mainly adopt the pressing method, the abrasives and the binders are weighed according to the weight ratio of the formula, mixed evenly in the mixer, put into the metal mold, and the abrasives are formed in the press. The blank is dried and then put into the kiln for roasting, and the firing temperature is generally about 1300℃. When the low melting point sintering bond is used, the sintering temperature is lower than 1000℃. Then machining accurately according to the specified size and shape, and finally check the product. Resin bonding abrades are generally formed on a press at room temperature, and hot pressing processes are also used to heat and press under heating conditions. After forming, it is hardened in a hardening furnace. When phenolic resin is used as binder, the hardening temperature is 180~200℃. Rubber bonding abrasives are mainly mixed by rolling machine, and rolled into thin sheets, and then blanked with a punching knife; Some also use loose material, put into the metal mold internal press molding. After forming, vulcanization in the vulcanization tank, the temperature is 165~180℃. There are two manufacturing processes of metal bonding abrasives: powder metallurgy and electroplating, mainly used for superhard abrasive consolidation abrasives. The powder metallurgy method uses bronze as a binder, which is formed by hot pressing or pressure at room temperature after mixing, and then sintered. The electroplating method uses nickel or nickel-cobalt alloy as electroplating metal, and the abrasive is consolidated on the substrate by electroplating process to make abrasive tools. Special varieties of grinding with sintered corundum abrasives and fiber abrasives. Sintered corundum abrasive is made by mixing alumina powder and appropriate amount of chromium oxide, forming, sintering at about 1800℃. This kind of grinding tool has tight structure and high strength, and is mainly used for processing parts such as clocks and meters. Fiber abrasives are made of fiber silk containing or adhering to abrasive (such as nylon silk) as raw materials, and its elasticity is good, mainly used for polishing metal materials and their products.

Usage situation

In the process of use, when the abrasive is dull, because the abrasive itself is partially broken or the bond is broken, the abrasive is partially or completely off from the abrasive, and the abrasive on the working surface continues to appear new cutting edges, or constantly reveals new sharp abrasive particles, so that the abrasive can maintain the cutting performance in a certain period of time. This self-sharpness of the grinding tool is a prominent feature of the grinding tool compared with the general tool. As early as the Neolithic Age, humans have begun to use natural grinding stones to process stone knives, stone axes, bone, horn and tooth tools; In the 19th century, the United States appeared with natural abrasive combined with clay fired ceramic grinding wheel; Around 1900, artificial abrasives came out, and various abrasives manufactured by artificial abrasives were produced successively, creating conditions for the rapid development of grinding and grinding machines. Since then, the proportion of natural abrasives in abrasives has gradually decreased.

Abrasives are divided into natural abrasives and artificial abrasives according to their raw material sources. The only natural abrasives commonly used in the machinery industry are oil stones. Artificial abrasives are divided according to the basic shape and structural characteristics, including grinding wheel, grinding head, whetstone, sand tile and above collectively referred to as consolidated abrasives and coated abrasives. In addition, it is customary to list abrasives as a class of abrasive tools.

Consolidated abrasives can be divided into ordinary abrasive consolidated abrasives and superhard abrasive consolidated abrasives according to the different abrasives used. The former is made of ordinary abrasives such as corundum and silicon carbide, while the latter is made of superhard abrasives such as diamond and cubic boron nitride. In addition, there are some special varieties, such as sintered corundum abrasives.

Common abrasive consolidation abrasives are abrasives which are consolidated into a certain shape by a binder and have a certain strength. Generally composed of abrasives, binders and pores, these three parts are often called the three elements of consolidated abrasives.

Abrasive plays a cutting role in abrasives. Binder is the material that consolidates loose abrasives into abrasives, there are two types of inorganic and organic. Inorganic binders include ceramics, magnesite and sodium silicate, etc. Organic ones include resin, rubber and shellac. Among the most commonly used are ceramic, resin and rubber binders.

During grinding, the porosity plays the role of chip storage and chip removal, and can contain the coolant, which is conducive to the dissipation of grinding heat. In order to meet some special processing requirements, the pores can also be impregnated with some fillers, such as sulfur and paraffin, to improve the performance of the abrasive tool. This filler is also known as the fourth element of abrasives.

Items that indicate the characteristics of ordinary abrasive consolidation abrasives are: shape, size abrasive, particle size, hardness, structure and bond. Abrasive hardness refers to the difficulty of the abrasive particle falling off the surface of the abrasive particle under the action of external force, which reflects the strength of the abrasive particle held by the binder.

Abrasive particle size

Particle size refers to the size of the abrasive particles, and its size is expressed by the particle size number.

The national standard specifies two particle sizes of abrasive and micro-powder.

Particle size refers to the size of the abrasive particle size. The particle size is divided into two types: abrasive particle and micro-powder. For large particle size cylindrical grinding wheel at 40μm abrasive, called abrasive particles. With the screening method, the particle size is indicated by the number of holes per inch in the screen through which the abrasive particles pass. For example, a 60 # abrasive particle indicates that it is just large enough to pass through a screen with 60 holes per inch of length. For abrasives with particle size less than 40μm, it is called micro-powder. Classification by micromeasurement method, with W and the following number to indicate the particle size, the value after W represents the actual size of the powder. For example, W20 indicates that the actual size of the powder is 20μm. The particle sizes of various particle sizes are shown in Table 1.

Table 1 Abrasive particle size and particle size

Abrasive particle

Abrasive particle

Micro powder

Size number

Grain size (um)

Particle size number

Grain size (um)

Size number

Grain size (um)

14 #

1600 ~ 1250

70 #

250 ~ 200

W40

40 ~ 28

16 #

1250 ~ 1000

80 #

200 ~ 160

W28

28 ~ 20

20 #

1000 ~ 800

100 #

160 ~ 125

W20

20 ~ 14

24 #

800 ~ 630

120 #

125 ~ 100

W14

14 ~ 10

30 #

630 ~ 500

150 #

100 ~ 80

W10

10 ~ 7

36 #

500 ~ 400

180 #

80 ~ 63

W7

7 ~ 5

46 #

400 ~ 315

240 #

63-50

W5

5-3.5

60 #

315 ~ 250

280 #

50 ~ 40

W3.5

3.5 ~ 2.5

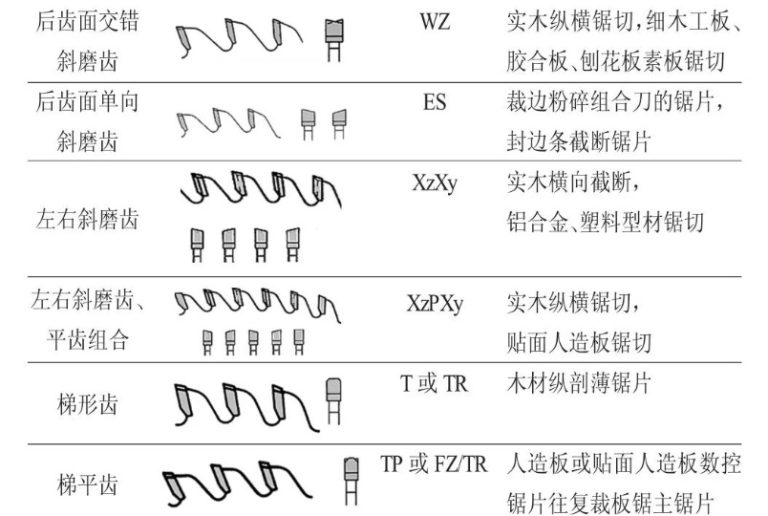

Table 2 Application range of grinding wheels with different grain sizes

Note: Abrasive particles coarser than 14 # and fine powders finer than W3.5 are rarely used and are not listed in the table. The choice of abrasive particle size is mainly related to the roughness and productivity of the machined surface. Coarse grinding, grinding allowance is large, the required surface roughness value is larger, should be selected coarser abrasive. Because of coarse abrasive grains and large pores, the grinding depth can be larger, and the grinding wheel is not easy to plug and heat. In fine grinding, the margin is small, the roughness value is low, and a finer grinding particle can be selected. Generally speaking, the finer the particle, the better the grinding surface roughness.

Binding agent

The role of the binder is to bond the abrasive into a grinding wheel with a certain strength and shape. The strength, impact resistance, heat resistance and corrosion resistance of the grinding wheel mainly depend on the performance of the bond.

Commonly used binders are ceramic binders (V), resin binders (B), rubber binders (R) and metal binders (M).

Ceramic bond: the most widely used, suitable for external round, internal round, surface, centerless grinding and form grinding wheels;

Resin bond: suitable for cutting and grooving wafer grinding wheel and high speed grinding wheel;

Rubber binder: suitable for centerless grinding guide wheel and polishing grinding wheel;

Metal bond: suitable for diamond grinding wheel, etc.

Abrasive hardness

The hardness of abrasives mainly depends on the amount of binder added and the density of abrasives, abrasive particles are easy to fall off, indicating low abrasive hardness; On the contrary, it means high hardness. Hardness grades are generally divided into super soft, soft, medium soft, medium hard, hard and super hard seven grades, from these grades can also be subdivided into a number of small grades. The commonly used methods to determine the hardness of abrasive tools include hand cone method, mechanical cone method, Rockwell hardness tester and sand blast hardness tester.

The hardness of abrasives corresponds to its dynamic elastic modulus, which is helpful to use audio method to measure the dynamic elastic modulus of abrasives to express the hardness of abrasives. In the grinding process, if the material hardness of the grinding part is high, the abrasive tool with low hardness is generally selected; On the contrary, the abrasive tool with high hardness is selected.

Magnesite abrasives

summarize

Magnesite abrasive tool is composed of magnesite cement and silicon carbide in a certain proportion, which not only inherits the advantages of high strength and high hardness of magnesite cement, but also retains the good wear resistance of silicon carbide.

peculiarity

1), high strength, high hardness, good wear resistance, with good grinding ability;

2), good copying, polishing and polishing fast, good gloss;

3), magnesite cement adhesive viscosity is good, the grinding block combination effect is good, no bounding;

4), less grinding, strong killing force, high grinding efficiency;

5), low cost, good wear resistance, has a very high cost performance.

use

Magnesite grinding tools are mainly used for rough grinding, medium grinding, fine grinding until polishing of ceramic tile, glass-ceramics and other surfaces, practicality, large amount, can be widely used in natural stone, ceramics, glass-ceramics and other non-metallic materials cutting, grinding and polishing, can reduce the time of changing tools, improve work efficiency, especially suitable for portable electric tools, hand-pushed cutting machines, automatic bridge cutting machines, etc. The market prospect is broad, and it is widely used throughout the country.

Relevant data

broadcast

Organic characteristics

Organic abrasive tools are characterized by a wide range of use, with a certain degree of elasticity and high bonding strength, and has good polishing performance. In rough, fine, fine, polishing and other grinding processes are used, the resin grinding tools have the following characteristics:

- High bonding strength

Compared with the ceramic binder, the resin binder has high bonding strength, and the grinding line speed of the resin wheel can reach 80~120m/s, and can withstand large grinding pressure. Heavy duty grinding wheel grinding pressure up to 10×104 ~ 40×104N, widely used in the iron and steel industry, such as various ingot, billet and other grinding processes. The coarse grinding process such as high-speed heavy load special grinding wheel has safe operation, suitable for high-speed grinding and large feed grinding, and high grinding efficiency.

2, with a certain degree of flexibility

Compared with ceramic abrasives, resin abrasives have good toughness and certain plasticity and ductility. Its elastic modulus (E) is dozens of times lower than that of ceramics. Therefore, resin grinding tools are suitable for the preparation of various specifications of wafer grinding wheels and high-speed cutting wheels. At the same time, due to a certain elastic deformation, it can buffer the effect of grinding force. Therefore, the grinding effect is good, the polishing effect is good, and the roughness of the machined surface can be improved.

3, can be made into a variety of complex shapes and special requirements of abrasive tools

Due to the low hardening temperature of the resin bonded abrasive, it can be hardened at room temperature, and the shrinkage rate is small, and it can be made into a variety of complex shapes and special requirements of abrasive tools. Such as: glass fiber reinforced resin grinding wheel, easy to remove chips, good heat dissipation porous resin grinding wheel and groove grinding wheel; Bolt-fastened grinding wheel, electrolytic grinding wheel, polishing wheel to improve grinding process conditions; And cylindrical, bowl, butterfly and other special-shaped grinding wheel.

4, wide range of application

Due to the variety of new resin bond, it can be made into various strength and performance of resin abrasive tools. Therefore, it can be widely used in rough grinding, rough grinding, cutting, semi-fine grinding, fine grinding, polishing and other processes. Resin grinding tools have high bonding strength, high speed and impact resistance, suitable for rough grinding and rough grinding. Resin grinding tool has good toughness, suitable for cutting process; Resin grinding has good elasticity, has a certain polishing property, can be used for fine grinding and polishing processing. Resin abrasive has low heat resistance, easy to wear, suitable for flat grinding and fine grinding.

5, is conducive to prevent the grinding of the workpiece burns

The resin bond has low heat resistance, which can reduce or avoid the phenomenon of burning the workpiece. The heat generated by the workpiece in the grinding process first carbonizes the resin, prompting the passivated abrasive to fall off automatically, exposing new sharp abrasive particles, reducing the heat in the grinding area and avoiding the workpiece burn.

6, resin abrasive hardening temperature is low, short production cycle, simple equipment

It is conducive to specialized production. The shortcomings lie in:

(1) Resin abrasive resistance to alkaline, water resistance is poor, easy to aging. The general valid storage period is one year. Therefore, it cannot be stored for a long time.

(2) Resin abrasive has low heat resistance, large wear during grinding, and is not suitable for shaping grinding.

(3) Low porosity of resin abrasive, processing odor, should pay attention to environmental pollution problems.

Organic application

Organic abrasives are resin abrasives, mainly used in steel, automobile, bearing, railway, vehicle, shipbuilding, chemical, instrumentation, aerospace, building materials and other mechanical processing industries. Can be used to process a variety of non-metallic materials and metal materials. Such as: wood, rubber, plastic, glass, ceramics, stone, copper, aluminum, cast iron, steel, etc., as well as hard alloy, high speed steel, high vanadium steel, titanium steel, stainless steel, etc. In addition, it can be used in the fields of grain processing, medicine and geological exploration.

According to the different processing purpose and dosage, rough grinding, rough grinding, semi-finishing grinding, fine grinding and high precision and low roughness grinding can be carried out. At the same time, according to the different processing objects, external grinding, internal grinding, surface grinding, tool grinding, special grinding, welding grinding, honing, super finishing, grinding and polishing.

1, rough grinding processing application

Rough grinding refers to a grinding method characterized by efficient cutting of a large number of redundant materials. Rough grinding is a common name widely used in many kinds of rough grinding.

Application field of rough grinding:

(1) Finishing of high quality alloy steel or stainless steel billet with resin grinding wheel and high speed heavy load resin grinding wheel, coarse grinding annealing or non-annealing. Used for grinding of surface appearance defects (welds, cracks, oxide layers, etc.).

(2) Use resin grinding wheel to grind and finish the gate, riser and blank joint of the casting.

(3) Use the resin grinding wheel to thoroughly remove the flash left after the repair of the die forging, the large burr of the forging or the gate.

(4) In the welding operation, the welding seam remaining on the surface of the weldment should be used to smooth the welding seam and circular grinding.

(5) When the large plate is gas cut into a round or other complex shape, the slag generated by the gas cut should be ground by a portable grinding machine. Such as: large hot rolled building steel and pipe cutting rough cutting processing.

2, hand-held grinding processing applications

Hand grinding is a comprehensive summary of grinding methods. Their common feature is that whether it is the workpiece or the support of the grinding machine, the workpiece is in contact with the abrasive tool, and the guidance and movement are directly dependent on manual work.

Hand-held grinding is divided into fixed hand-held grinding and mobile hand-held grinding. The way in which the grinding machine is fixed and the workpiece is grinded by hand is called fixed hand grinding. The hand-held grinder used in processing is a mobile grinding mode, which is called mobile hand-held grinding.

Main application areas of hand-held grinding:

(1) Use portable resin grinding wheel to process large and bulky workpieces that are difficult to install on the grinder. Such as: coarse grinding of large castings.

(2) Use high-speed cymbal grinding wheel or steel paper grinding disc to process the workpiece that has been assembled with other ‘parts. Such as: heavy building components and ship components.

(3) Grinding required for small adjustments. For example, calibration of assemblies on limited parts of common large components.

(4) With high-speed cymbal grinding wheel, etc., the workpiece is finally formed or the workpiece is rounded at the joint of the adjacent part, and the workpiece has been assembled or has been welded for grinding. For example: the processing of automobile body.

(5) For sculpture processing on irregular surfaces. Such as: mold processing.

(6) Workpiece finishing processing. That is, the workpiece is required to be rounded or polished grinding, so that the surface is beautiful and the performance is satisfactory, and there are no strict requirements on the shape and size. Such as: processing stainless steel products with flexible cymbal grinding wheel, processing stone with PVA grinding wheel.

(7) Do a small amount of grinding on the limited area of the workpiece surface in order to form a special shape, such as: sharpening of various tools.

3, cutting processing applications

Resin sheet grinding wheel is mainly used for cutting and processing steel bar, steel pipe, flat steel, Angle iron, channel steel, steel rail, steel plate and other metal materials in metallurgical industry. Semiconductor industry silicon, germanium, sapphire, ferrite, graphite, ceramics, quartz and other metal and non-metallic materials precision ultra-thin slice processing; Like and building materials industry, chemical industry, aerospace industry, machinery industry, automotive industry, shipbuilding industry of metal materials and non-metallic materials cutting processing.

In the cutting of metal materials, the use of resin sheet grinding wheel cutting, has the following advantages:

(1) Fast cutting speed. When cutting metal materials, the cutting speed of the cutting wheel is 10 times that of other cutting methods (such as sawing and turning).

(2) High cutting dimensional accuracy. When cutting with grinding wheel, the width of the incision and the flatness of the cutting surface are generally better than that of the metalworking saw.

(3) The cutting surface is smooth. After grinding wheel cutting, the surface often does not need to be finished, and the cutting surface after sawing is obvious.

(4) Can be used for cutting hard materials. Such as hardened steel and metal carbide and hard and brittle non-metallic materials cutting processing.

(5) During the use of abrasive tools, self-sharpening is good and does not need to be trimmed.

(6) Low cost. The cost of cutting with grinding wheel is significantly lower than other cutting methods.

(7) Other applications. Such as narrow slot incision, or the cutting of hardened steel or superhard non-metallic workpiece.

These characteristics of resin abrasive cutting make it widely used in many metal processing industries and non-metal processing industries, as well as in other fields of industrial production.

4, conventional grinding processing applications

(1) Grinding the cylindrical, conical and shoulder surfaces of shafts, sleeves and other types of parts with resin grinding wheels on an external grinder or universal grinder.

(2) Using the outer circumferential surface of the resin grinding wheel or the end face of the grinding wheel, such as bolt-tightened grinding wheel, large porosity grinding wheel, slotted grinding wheel, porous grinding wheel and porous grooved grinding wheel, as well as the end face of the multi-purpose cup grinding wheel and cylindrical grinding wheel, the various flatness of the mechanical parts to meet the requirements of flatness, surface roughness and mutual position accuracy.

(3) Using the outer surface or resin grinding head of the resin grinding wheel, the inner grinding machine, the universal grinding machine or the special grinding machine, the inner grinding machine for the through hole, blind hole, step hole, cone hole and bearing inner channel and other parts with higher surface quality requirements.

(4) Using resin grinding wheel, resin and rubber guide wheel, on the centerless grinder, using the flexible positioning method, using the outer peripheral surface of the grinding wheel, to carry out centerless grinding processing on the inner or outer surface of the rotation symmetry.

(5) Use special resin grinding wheel to grind thread grinding wheel. On the thread grinding machine, the high precision and surface roughness of the drive thread, the thread of the measuring machine, the thread of the measuring tool and the hardening of the thread part are threaded. Such as thread, worm, tap, hob, gauge and other taper thread, multi-thread, parallel thread grinding processing.

(6) Using epoxy resin honing wheel and double cone, butterfly, double butterfly, worm type grinding wheel, etc., on the gear grinding machine, gear grinding is carried out on the hardened gear.

(7) With resin strong grinding wheel, in the tool grinding, the cutting tool materials with high hardness and hardness, wear resistance and enough strength and toughness, such as carbon tool steel, alloy tool steel, high-speed steel, cemented carbide, etc., are grinding tools to achieve the ideal accuracy, surface roughness and correct geometry. The cutting tool has high sharpness and durability.

5, other special grinding processing applications

(1) Use resin to grind the rail grinding wheel to grind the rail on the special rail grinding train.

(2) With conductive resin grinding wheel, on the electrolytic grinding machine, some high-hardness parts, such as various cemented carbide cutting tools, measuring tools, extrusion drawing dies, rolls, etc., and ordinary grinding is difficult to process small holes, deep holes, thin-walled tubes, slender rod parts and complex surface parts, electrolytic grinding processing. Electrolysis accounts for 95% of the processing volume. The machining effect of abrasives is only 5%. Therefore, electrolytic grinding is more efficient than ordinary grinding.

(3) With PVA (polyvinyl alcohol) polishing wheel, PU (polyurethane) polishing wheel, non-woven polishing wheel, etc., on the polishing machine, polishing stone, glass, stainless steel and so on.

(4) Grinding tape recorder magnetic head, watch, instrument industry used fine grinding grinding wheel. Such as FBB (water resistant polyvinyl alcohol) grinding wheel.