What are the advantages of SDs drill bits?

Key Advantages of SDS Drill Bits

Compatibility & Ease of Use

SDS drill bits feature a two-groove, two-notch round shank design, allowing them to be quickly inserted into a spring-loaded chuck without tightening, making operation fast and effortless. Additionally, SDS bits are compatible with all SDS Plus hammer drills, working across various brands and models for broad applicability.

Durability & Wear Resistance

SDS bits are typically made from high-alloy steel and produced via optimized hardening techniques, ensuring exceptional wear resistance. For example:

- SDS Plus-3 bits use high-alloy steel with advanced hardening for extreme durability.

- Bosch carbide-tipped bits feature ultra-durable alloy heads, ideal for high-strength materials like reinforced concrete.

High-Efficiency Drilling Performance

- Multiple flutes for effective dust removal, enhancing durability (e.g., SDS Plus-3’s 4-flute design boosts drilling efficiency).

- 4-edge carbide tips enable rapid penetration through reinforced concrete.

Lithium Hammer Drill Bit Selection Guide: SDS Systems & Applications

I. Comparison of Mainstream Bit Systems

- SDS-Plus System Features

- Hole range: 4–30mm

- 85% impact energy transfer efficiency

- Quick-lock mechanism (0.5s bit changes)

- Typical uses: Electrical box installations, anchor bolt fixing

- SDS-Max System Advantages

- Max hole size: 50mm

- Triple-buffer design reduces 30% recoil

- Tungsten carbide heads last 3× longer

- Typical uses: Wall penetration, HVAC ductwork

II. Key Selection Factors

- Material Hardness Matching

- C30 concrete or softer: SDS-Plus

- Reinforced concrete: SDS-Max

- Power Compatibility

- 18V tools: SDS-Plus only

- 36V+ tools: Dual-system support

III. Dayi Lithium Hammer Solutions

- Genuine Bit Identification

- Laser-etched anti-counterfeit codes

- Blue anodized finish

- Extreme Condition Tips

- Deep holes: Use spiral-flute bits

- Continuous work: Inspect shank wear every 2 hours

IV. Maintenance Guidelines

- Routine Care

- Clean chuck slots with compressed air

- Apply silicone-based lubricant

- Retirement Criteria

- Edge damage >2mm

- Shank deformation >0.5mm

Pro Tip: Professional bits should meet ISO 5468 standards. Always conduct a no-load test before use.

Why Telecom Engineers Prefer SDS Hammer Drills

Core Advantages

- High Efficiency: Dual drill/hammer function excels on hard materials.

- Precision: Accurate positioning for clean holes.

- Ease of Use: SDS chuck enables tool-free bit changes and multi-brand compatibility.

- Adjustability: Flexible drilling angles enhance versatility.

Telecom Applications

- Installing communication equipment

- Maintenance/upgrade drilling

- Cable routing modifications

Maintenance Tips

- Replace worn bits regularly.

- Clean drill body post-use.

- Remove internal debris from the chuck.

- Inspect motor vents and contacts.

China’s Consumables Market: The Confused Hammer Drill Bit

A Brief History

- 1914: FEIN invents the first pneumatic hammer.

- 1932: Bosch develops the first SDS system for electric hammers.

- 1975: Bosch & Hilti co-create SDS-Plus, revolutionizing construction drilling.

How Hammer Drills Work

A hammer drill combines rotation + axial hammering (via a piston-driven impact mechanism), making it ideal for concrete/stone but unsuitable for metal/wood/plastic.

Drawbacks: High vibration, dust/noise, and potential structural damage.

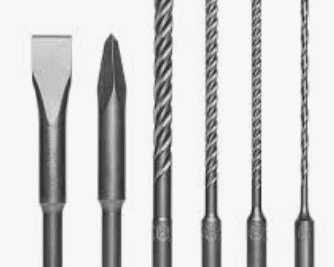

SDS Bit Types Explained

- SDS-Plus (2-notch/2-groove round shank)

- Quick-insert chuck (no tightening needed).

- Slides like a piston for efficient hammering.

- Standard for 4–30mm holes (110–1500mm lengths).

- SDS-Max (5-notch round shank)

- Heavy-duty upgrade (18mm shank, handles 13–44mm holes).

- Triple-open + two closed grooves for anti-kickback.

Note: SDS trademarks remain Bosch-owned; unauthorized use is restricted.

Why China Uses Square-Shank Bits

- Legacy adoption: Japanese brands (Makita/Hitachi) introduced square shanks early in China.

- Market inertia: No functional advantage over SDS-Plus, but local manufacturers stuck with tradition.

- Bosch’s dilemma: Despite late entry with square-shank drills, domestic brands already dominated 80% of the market.

Key Insight: Round shanks offer better concentricity and precision, but Bosch’s delayed response ceded the market to Chinese brands.

Read more about aluminum roll film.