What is a grinder Machine?

There are several meaning of grinder machine. When we look in dictionary. “a machine or device for grinding”. In a kitchen, a grinder is a device for crushing food such as coffee or meat into small pieces or into a powder. A grinder is a machine or tool for sharpening, smoothing, or polishing the surface of something.

Grinding, a term synonymous with precision and efficiency in material removal, stands at the forefront of modern manufacturing techniques. This article delves into the grinding process, exploring its mechanics, applications, and evolution.

Grinding, as a type of machining, is used to complete workpieces that must have high surface quality (e.g., low surface roughness) and high shape and dimensional accuracy. Since the dimensional accuracy of grinding is about 0.000025 mm, in most applications it tends to be finished, removing relatively little metal, about 0.25 to 0.50 mm depth. However, in some roughing applications, grinding can remove large amounts of metal fairly quickly. Therefore, grinding is a diverse field.

Grinding Machine sometimes refers to polishing machine:

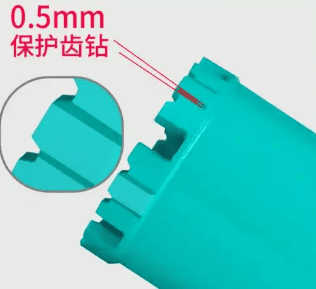

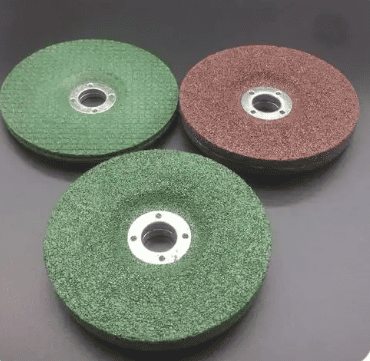

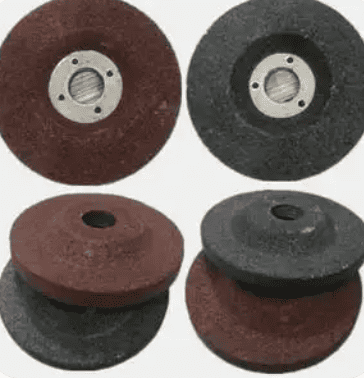

- Polishing machines, also known as grinders, are often used for mechanical grinding, polishing and waxing. The working principle is: the motor drives the sponge or wool polishing disc installed on the polishing machine to rotate at high speed, because the polishing disc and polishing agent work together and friction with the surface to be polished, and then can achieve the purpose of removing paint pollution, oxidation layer and shallow marks. The speed of the optical disc is generally 1500-3000 r/min, mostly stepless variable speed, which can be adjusted at any time according to the need during construction.

- Types: 1) According to the power source, there are two kinds of pneumatic and electric. Pneumatic is safer, but requires an air source; It is easy to solve the power supply problem, but we must pay attention to the safety of electricity.(2) According to the function, there are two kinds of dual-function industrial grinding/polishing machine and simple polishing machine. The dual-function industrial abrasive polishing machine is equipped with a grinding wheel to polish the metal material, and can be replaced with a polishing disc for car paint. This machine is heavy, 2-3 kg, but it works very smoothly and is not easy to damage. The speed of this model can be adjusted, suitable for professional beauty care personnel. Simple polishing machine is actually a drill, small size, speed is not adjustable, difficult to grasp the balance when using; Professional beauty care professionals generally do not use such models.(3) According to the speed of the classification of high-speed polishing machine, medium speed polishing machine and low speed polishing machine three kinds. The speed of the high-speed polishing machine is 1750-3000 r/mAn, the speed is adjustable; The speed of the medium speed polishing machine is 1 200-1 600 r/rain, the speed is adjustable; The speed of the low-speed polishing machine is 1 200r/min, and the speed is not adjustable.

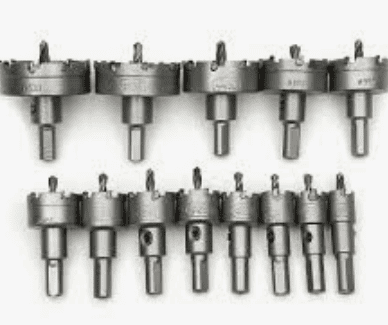

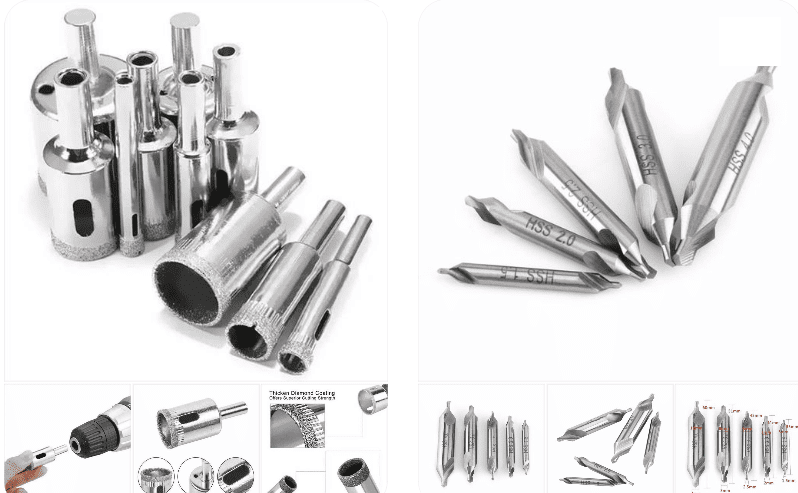

Relative Products

Polishing Machine Angle Grinder Hand Polishing machine Die Grinder

Grinding Machine sometimes means Pulverizer:

The pulverizer is a high-speed rotating pulverizer used to crush, grind and mix various substances. It is usually composed of a motor, a grinding chamber and a grinding body (such as a grinding ball or a grinding disc). When the motor is running, the grinding body rotates rapidly in the grinding chamber, so that the material to be ground is crushed, ground and mixed under the action of the grinding body. Crusher is widely used in chemical, biological, agricultural, mining, pharmaceutical, food and many other fields, used to crush ore, chemical, pharmaceutical, food and other materials. The grinding machine has high grinding efficiency and convenient operation. It is an indispensable device in many industries.

Grinder sometimes means grinding mill:

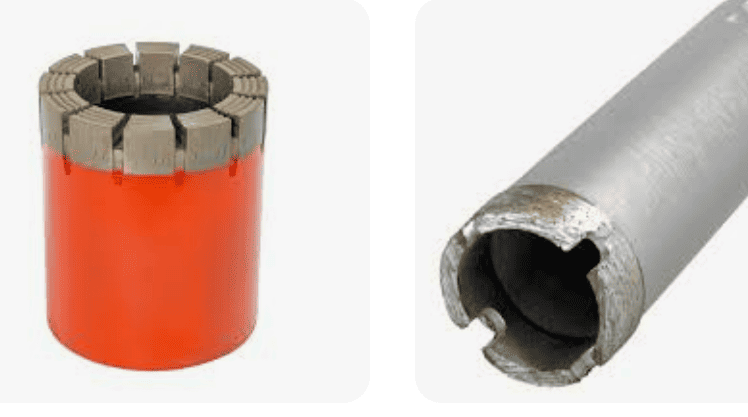

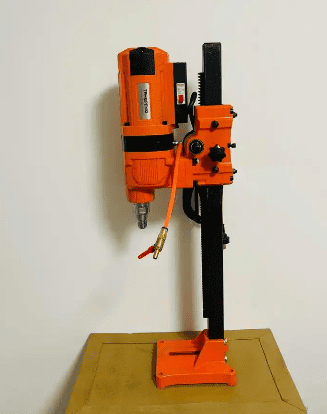

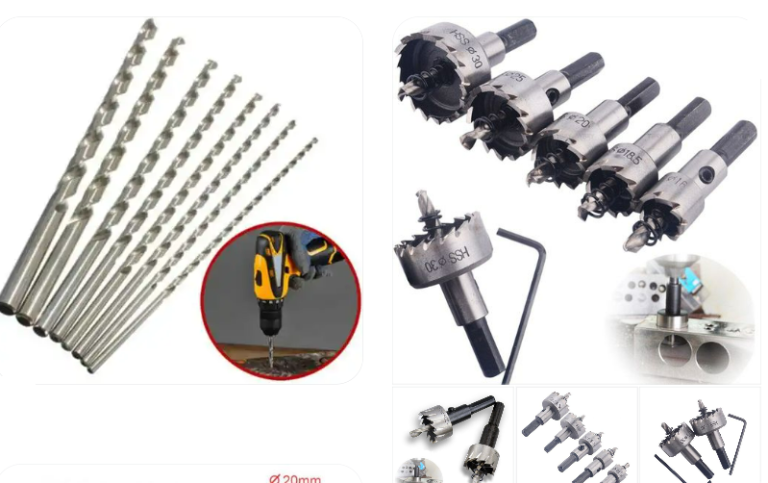

The grinder consists of a bed with a clamp and a power-driven grinding wheel that rotates at the desired speed. The diameter of the wheel and the manufacturer’s rating determine the speed. The grinding head can be moved on the fixed workpiece, or the grinding head can be held in a fixed position while the workpiece is moving.

Fine control of the position of the grinding head or table is possible, using a vernier to calibrate the handwheel or using digital control features.

The grinder removes material from the workpiece through wear, which can generate a lot of heat. In order to cool the workpiece so that it does not overheat and exceed its tolerance, the grinder uses a coolant. Coolant also benefits mechanics, as the heat generated can cause burns. In high-precision grinders (most cylindrical and surface grinders), the final grinding stage is usually set to about 200 nanometers (less than 1/10,000 inch) per pass – this produces so little heat that the temperature rise is negligible even without coolant.

Click to see more information if you are interest in following topics:

Sifter and Vibrating Machine for Screen Dry Powder