Die grinder vs angle grinder

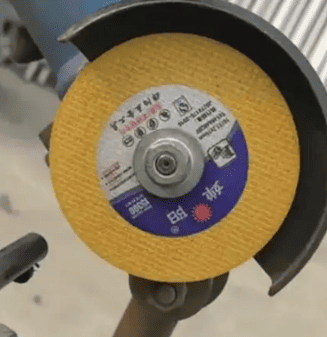

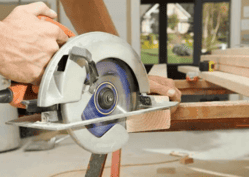

angle grinder (angle grinder), also known as the grinder or disk grinder, is a type of grinding tool used for cutting and grinding glass steel. Angle grinder is a portable electric tool for cutting and grinding glass steel, mainly used for cutting, grinding and brushing metal and stone.

Common models of Angle grinding machines are divided into 100 mm (4 inches), 125 mm (5 inches)150 mm (6 inches), 180 mm (7 inches) and 230 mm (9 inches) according to the specifications of the accessories used, and the small-size Angle grinding machines used in Europe and the United States are 115 mm.

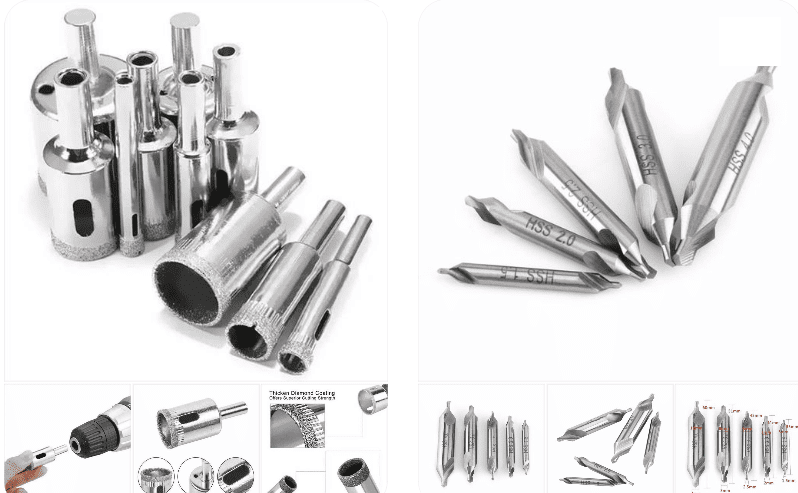

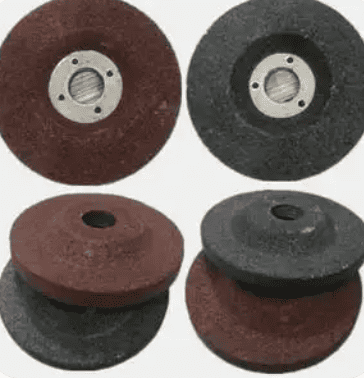

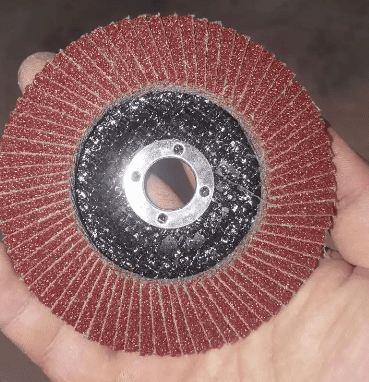

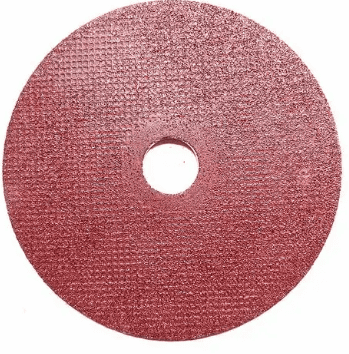

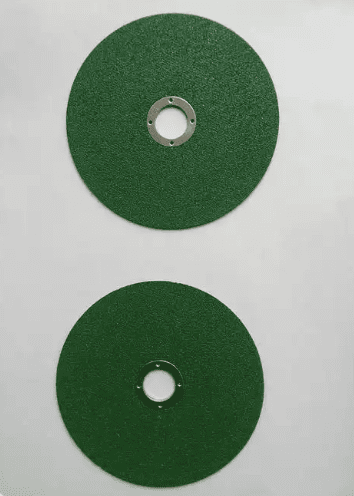

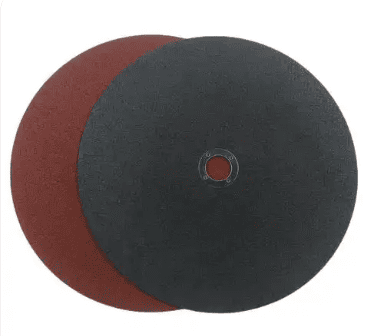

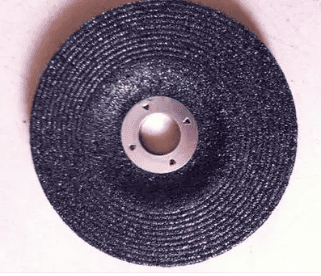

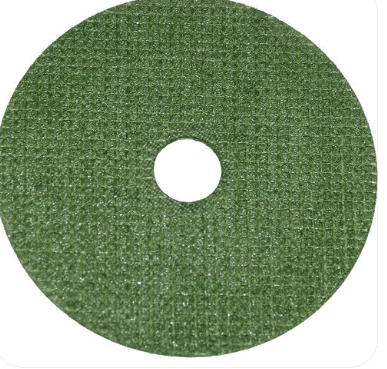

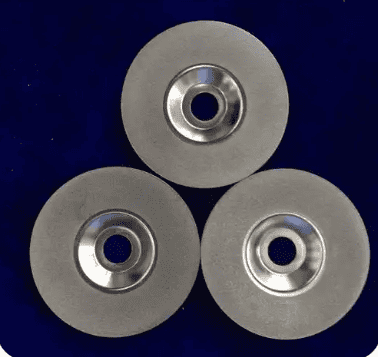

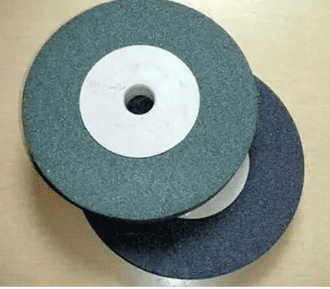

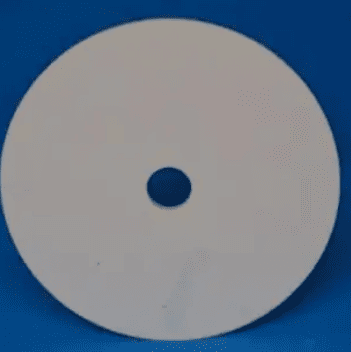

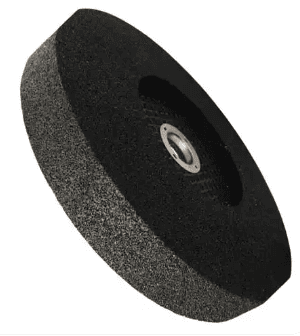

Electric Angle grinding machine is the use of high-speed rotating wafer grinding wheel, rubber grinding wheel, steel wire wheel and other metal components for grinding, cutting, rust removal, polishing processing. Angle grinding machine is suitable for cutting, grinding and brushing metal and stone, do not use water during operation. A guide plate must be used when cutting stone. For models equipped with electronic controls, grinding and polishing can also be performed if suitable accessories are installed on such machines.

Many uses, woodworkers, bricklayers, welders are commonly used.

The installation of the grinding wheel is a small portable grinding wheel cutting machine, which can cut and polish small metal parts, engaging in metal processing such as stainless steel anti-theft Windows, light box production, it is indispensable angle grinder (angle grinder), also known as grinding machine or disk grinder, is a kind of grinding tool for cutting and grinding glass steel. Angle grinder is a portable electric tool for cutting and grinding glass steel, mainly used for cutting, grinding and brushing metal and stone.

Common models of Angle grinding machines are divided into 100 mm (4 inches), 125 mm (5 inches)150 mm (6 inches), 180 mm (7 inches) and 230 mm (9 inches) according to the specifications of the accessories used, and the small-size Angle grinding machines used in Europe and the United States are 115 mm.

Electric Angle grinding machine is the use of high-speed rotating wafer grinding wheel, rubber grinding wheel, steel wire wheel and other metal components for grinding, cutting, rust removal, polishing processing. Angle grinding machine is suitable for cutting, grinding and brushing metal and stone, do not use water during operation. A guide plate must be used when cutting stone. For models equipped with electronic controls, grinding and polishing can also be performed if suitable accessories are installed on such machines.

Many uses, woodworkers, bricklayers, welders are commonly used.

The installation of the grinding wheel is a small portable grinding wheel cutting machine, which can cut and grind small metal parts. It is indispensable for metal processing such as stainless steel anti-theft Windows and light boxes. 1: The electric motor of the grinding machine uses 220 volts alternating current, and the power is generally 120-250 watts. With stepless speed regulation, the speed can be controlled at 8000-30000 RPM.

2: The soft whip of the electric mill is a hollow soft cable set with a free rotation of the wire rope, the end of the soft whip is connected with a pen-like sleeve, the length of the pen-like sleeve is about 15 cm, the diameter is about 2 cm, the sleeve core is connected by the soft cable and the motor; Because of its small size, the operation is very flexible and convenient.

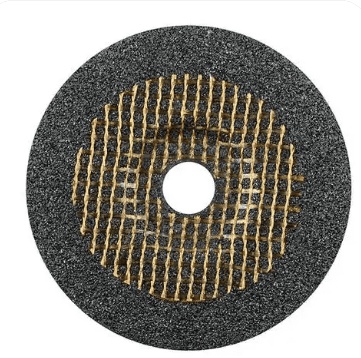

JD103H micro electric mill

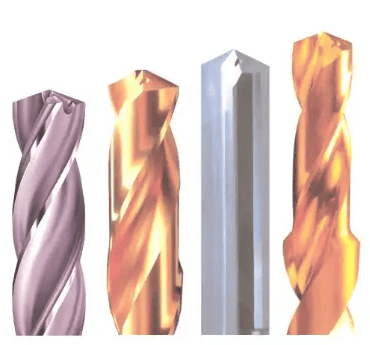

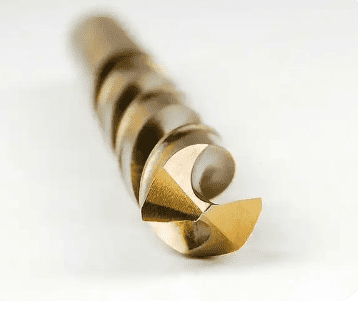

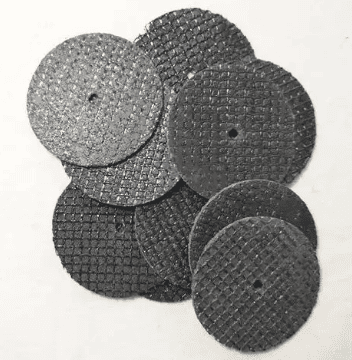

3: accessories for the electric mill; The socket can be installed 0.3-2mm drill bits, in addition to the drill accessories, other accessories, such as cutting pieces, grinding head, polishing etc. are connected by a shaft with a diameter of 2mm. The diameter of the cutting sheet is about 25mm. Due to its small diameter, the cutting direction can be changed at will to make the cut with a pattern. The width of the cut is not more than 1mm. Different materials can be used to cut different materials such as iron, aluminum, alloy, wood, plastic, etc. Cutting pieces and carving heads with emery can be used to carve patterns on glass and jade.

4: Micro electric mill: there are three parts of the control box and the handle, the foot speed switch, because its speed is higher than the large electric mill (30,000-50000 RPM to choose from, feeling smooth, almost can not feel the shake, more suitable for fine engraving, seal cutting, polishing and other operations.

We OEM your brand and also color box, printed bags, outer box packages.

Click to see more industrial information about Packing Machine, sealing capping machine, printing Machine, grinding machine, mixing machine, or production line, new resources industries, such as ev charger, printing film, packing film, printed bags…