Yes, SDS drill bits are suitable for drilling into bricks.

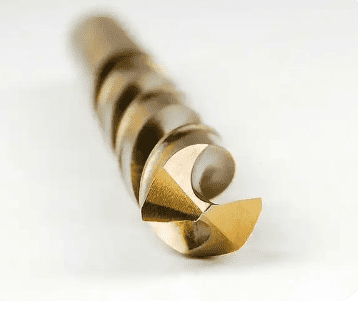

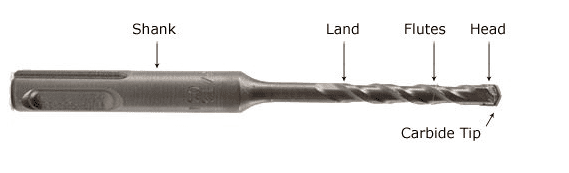

SDS drill bits, especially impact drill bits such as SDS drill bits or hammer drill bits, combine rotation and hammering action to penetrate hard cementitious materials, making them highly effective for drilling into bricks.

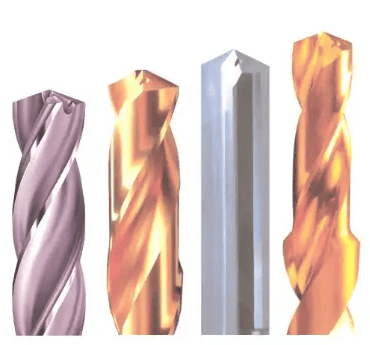

Types of SDS Drill Bits and Their Applications

- Impact Drill Bits: These bits combine rotation and hammering action, ideal for drilling into concrete and cement walls¹.

- Chisel-Tip Drill Bits: Designed to penetrate concrete and stone, their cutting edges withstand high pressure and impact forces¹.

- Rotary Hammer Drill Bits: Used with hammer drills, specifically designed for bricks, concrete, and other hard materials.

- Carbide-Tipped Drill Bits: Feature tungsten carbide cutting tips, suitable for various hard materials.

Recommended SDS Drill Bit Brands

Bosch offers durable SDS drill bit series, including the EXPERT and PRO lines. For example, the EXPERT SDS-MAX 5-flute 8-series hammer drill bit lasts three times longer than Bosch’s SDS-MAX 4-series bits, thanks to its advanced carbide technology.

Choosing the Right Shank Drill Bit for Brick Walls

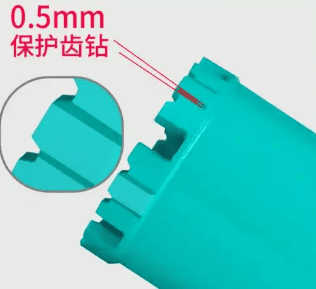

When drilling into brick walls with a drill or hammer drill, SDS-Plus or SDS-Max shank bits are recommended. These are specifically designed for masonry and offer excellent impact transfer and durability.

1. Differences Between Drills and Hammer Drills

- Drills: Primarily for drilling.

- Hammer Drills: Add hammering action, making them better for hard materials like brick and concrete.

2. Types of Shank Drill Bits

- SDS-Plus: Best for medium-power hammer drills, offering good impact transfer for brick walls.

- SDS-Max: Designed for high-power hammer drills, with a sturdier build for harder materials and larger holes.

3. How to Choose the Right Shank Bit

- Power: Use SDS-Plus for low-to-medium power drills; SDS-Max for high-power hammer drills.

- Material & Hole Size: Both work for brick, but SDS-Max is better for larger holes.

4. Usage Tips

- Ensure the bit matches the drill’s chuck to prevent slippage.

- Check for hidden wires/pipes before drilling.

- Maintain a steady grip to avoid bit deflection.

- Clean the bit regularly to maintain sharpness.

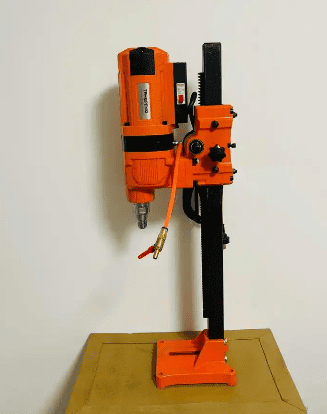

Hammer Drills vs. Rotary Hammers: Features & Usage Guide

Functions & Applications

- Hammer Drills: Combine rotation + hammering for concrete, stone, etc.

- Rotary Hammers: Add electropneumatic hammering, making them more efficient for heavy-duty tasks.

Bit Types

- Cylindrical Shank Bits: For soft materials (bricks, soft concrete).

- SDS-Plus/SDS-Max Bits: For hard materials (concrete, reinforced concrete, granite).

Tri-Function Drills (New Trend)

Lightweight 3-mode hammer drills (drill, hammer drill, chisel) offer versatility for various tasks.

Masonry Drill Bits: SDS-Max for Exterior Walls

🛠️ Perfect for contractors! Our SDS-Max exterior wall drill bits make drilling into brick, cement, and hard materials quick and professional.

🔩 Available Sizes & Prices:

- 12mm SDS-Max: $50

- 2-1/2”: $60

- 4-1/4”: $80

🏠 Applications:

- Red brick walls

- Cement walls

- Indoor/outdoor renovations

Can Tile Drill Bits Drill Cement Walls?

Tile bits (with diamond/carbide tips) are designed for hard, brittle surfaces like ceramic. While they can drill cement walls, they’re not ideal due to:

- Rapid Wear: Tile bits degrade faster in cement.

- Low Efficiency: Lack the impact force needed for cement.

- Safety Risks: Overheating/breakage may occur.

Best Bits for Cement Walls

✅ Hammer drill bits (SDS)

✅ Chisel-tip bits

✅ Rotary hammer bits

✅ Carbide-tipped bits

How to Drill Cement Walls Properly

- Select the right bit (e.g., SDS).

- Secure the bit in the drill.

- Mark the spot with a pencil.

- Set the drill to “hammer” mode.

- Drill slowly, increasing speed gradually.

- Clear debris to prevent overheating.

- Withdraw the bit carefully after drilling.

Pro Tips

- Use coolant (water) to extend bit life.

- Avoid excessive pressure.

- Wear safety goggles and gloves.

Conclusion: While tile bits can drill cement, specialized masonry bits (SDS, carbide, etc.) are safer, faster, and more durable.

Industrial News

Industrial Tech Knowledge

Industry Information:

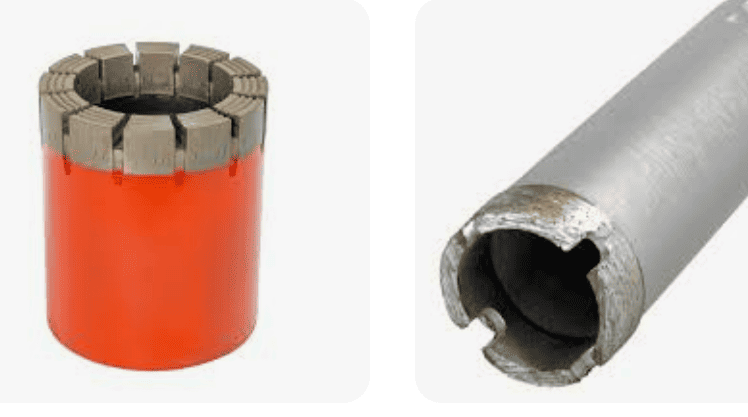

The aperture range of core drills varies depending on their application: Industrial Sector Medical Equipment Sector For more precise parameters, it is recommended to consider the specific application scenario (e.g.,…

yes, a core drill can cut through rebar. 1. Can Hollow Drills Penetrate Rebar? Hollow drills are tools capable of drilling through concrete and rebar, but they cannot penetrate rebar…

Hollow drills can penetrate metal. A hollow drill is an industrial drilling tool that removes material through a multi-blade annular cutting structure, primarily used for machining metal materials. Its design…

How to Identify Whether a Drill Bit is for Concrete or Wood 1. Bit Shape 2. Material 3. Performance Feedback Conclusion: Check shape, material, and drilling feel to avoid misuse…

What is the difference between a hole saw and a knockout punch? I. Definitions and Structures of Hole Saws and Knockout Punches A hole saw is a hollow drill bit…

Each drill bit can drill 1,000–3,000 holes. For example, drilling a 40mm diameter hole in 30mm thick steel plate takes only 25–40 seconds. When used with a magnetic drill, the…

Are Drill Bit Models Universal? Can All Types of Bits Be Used with Any Drill? Drill bits are not universally compatible—different bit models are designed for specific types of drills…

The Difference Between Core Drills and Hammer Drills I. Principle and Applications of Core Drills A core drill is a hollow drilling tool with an inner drill bit that can…

1. Structure Hollow drills and twist drills have different structures. A hollow drill has a hollowed-out center, leaving a sharp-edged bit, which generates more chips during drilling. A twist drill,…

How to Install a Core Drill Bit onto a Hand Drill In magnetic drill operations, the selection of drill bits is crucial. The core drill bit, as one of the…

What kind of drill is a hollow drill bit paired with? Choose the right drill bit to improve work efficiency. Hollow drill bits need to be used with specialized drill…

Core Drill Bit A hollow drill bit is also known as a core drill bit, hole opener, center drill bit, steel plate drill bit, magnetic drill bit, rail drill bit,…

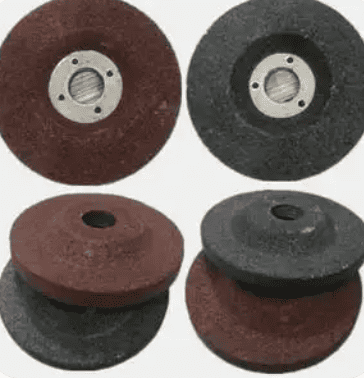

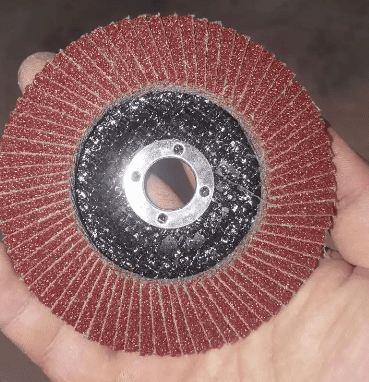

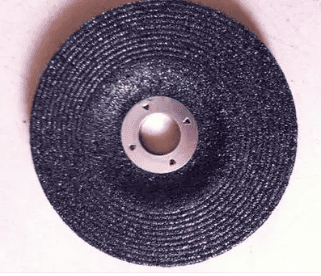

For grinding lawn mower blades, grinding wheel discs are better. Comparison of the Advantages and Disadvantages of Grinding Wheel Discs and Flap Discs Types and Applications of Grinding Wheel Discs…

Direction of Placing the Grinding Wheel: Which Side Should Face Up? I. Direction of Placing the Grinding Wheel Many people wonder which side of the grinding wheel should face up…

Resin Bond Diamond Grinding Wheel TestWheel Specification: 12A2/45°125×32×32×10×3 W20 100BGrinding Object: Sharpening PCD toolsGrinding Area: Two edges of PCD tool, edge width 4.6mm, PCD layer thickness 0.8mm, YG16 layer thickness…

Is It Time to Replace Your Grinding Wheel? A Comprehensive Guide to Wheel Replacement and Dressing In the field of grinding, the condition of the grinding wheel plays a decisive…

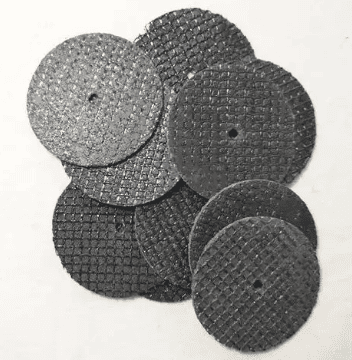

Can Cutting Discs Be Used for Grinding? Although cutting discs are primarily designed for cutting and grinding, they can also be used for polishing in many cases. 1. Uses and…

Identifying Cracks and Fractures in Grinding Wheels Before Use Before using a grinding wheel, it is essential to thoroughly inspect it for cracks or fractures to ensure safety. 1. Why…

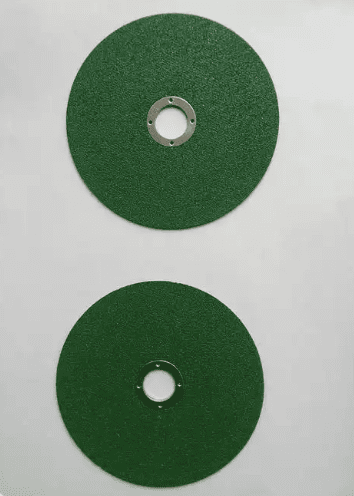

Pre-Installation Preparations and Checks for Grinding Wheels Before installing a grinding wheel, the following preparations and inspections must be conducted: Installation Steps Grinder Operation Procedure 1. Preparations Before operation, ensure:…

Detailed Explanation of Abrasive Grit Size: A Comprehensive Analysis from Coarse to Fine Abrasive grit size, more accurately referred to as “particle size distribution,” is commonly denoted by terms like…

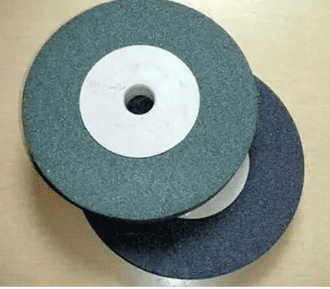

The Complete Guide to Grinding Wheel Selection: A Comprehensive Analysis from Structure to Abrasives Fundamentals of Grinding Wheels Understanding the basic principles of grinding wheels is key to selecting the…

own aluminum oxide has high hardness and toughness, making it suitable for grinding metals with high tensile strength, such as carbon steel, alloy steel, malleable cast iron, and hard bronze…

When using a grinding wheel machine, the operator must wear a safety helmet, protective goggles, and gloves, and should not face the grinding wheel directly but stand to the side…

Can Angle Grinders Cut Wood? Safety & Usage Guide Key Takeaways I. Risks of Cutting Wood with an Angle Grinder II. If You Must Use an Angle Grinder for Wood…

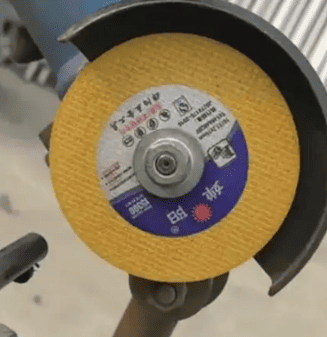

Angle Grinder Cutting Disc Usage Guide: Methods & Safety Precautions I. Proper Usage of Cutting Discs with Angle Grinders II. Critical Safety Measures III. Step-by-Step Installation Guide Pro Tip: Always…

Drill Bit Model Numbers: A Comprehensive Guide Drill bit model numbers consist of letters and numbers that indicate critical specifications including diameter, shank size, flute length, and material composition. Understanding…

Can Angle Grinders Cut Materials? Can They Use Cutting Discs? 1. Why Angle Grinders Are Not Ideal for Cutting Angle grinders are primarily designed for grinding and polishing, not cutting…

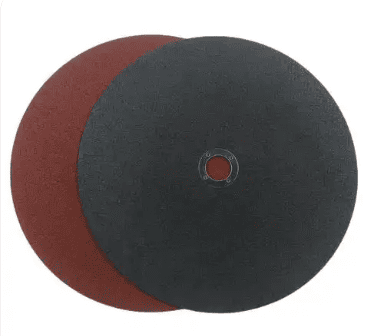

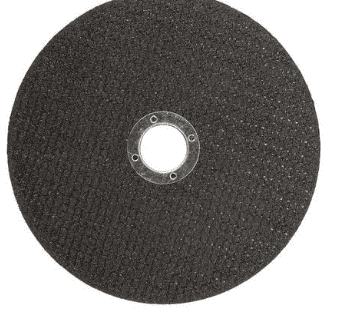

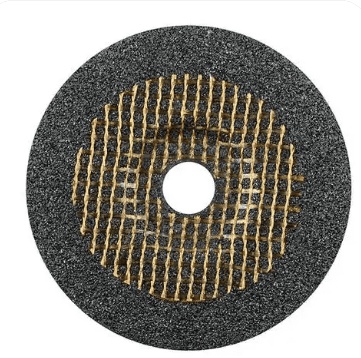

What’s the Difference Between Grinding Wheels and Cutting Discs? 1. Definitions and Applications 2. Structure and Materials Feature Grinding Wheel Cutting Disc Abrasives Aluminum oxide, silicon carbide, boron carbide Silicon…

Safe to Use a Cutting Disc for Grinding?No, It Is Not Safe. Why Cutting Discs Should Never Be Used for Grinding Using cutting discs (on angle grinders or cut-off tools)…

Materials That Should NOT Be Cut with Grinding Wheels Grinding wheels are designed for hard, non-combustible materials like metals and stone. However, certain materials pose safety risks or can damage…

While physically possible, using cutting discs on bench grinders significantly increases accident risks. Can Bench Grinders Use Cutting Discs? Safety & Usage Guide Key Considerations: If Absolutely Necessary:✔ Disc Selection:…

Yes, SDS drill bits are suitable for drilling into bricks.SDS drill bits, especially impact drill bits such as SDS drill bits or hammer drill bits, combine rotation and hammering action to penetrate hard cementitious materials,…

How much torque does a SDs drill have? 90 Newton Meters normally.The torque of an SDS drill bit is typically 90 Newton meters. An SDS drill bit is a specialized tool designed for…

SDS drill bits cannot be used as screwdrivers. SDS drill bits are designed for drilling, and their structure and material composition make them unsuitable for driving screws, which may lead to…

Key Differences Between Rotary Hammers and SDS Drills The primary distinctions between rotary hammers and SDS drills lie in their design principles, applications, and chuck systems. 1. Design Principles and…

DS mean on a rotary drill? The official term for hammer drill bits is “rotary impact drill bits”, also known as “SDS drill bits”. SDS stands for “Steck-Dreh-System” (Insert-Twist-Secure system),…

SDS drill bits are primarily used for drilling into hard construction materials such as concrete and brick, offering high efficiency and durability. SDS drill bits are specially designed for drilling…

Not all SDS drill bits come with a chuck. SDS drill bits are generally divided into two types: SDS-plus and SDS-max, both of which require compatible chucks for proper use…

SDS Drill Bits Suitable for Metal Do Exist For example, Bosch’s GSB120 Dual-Power Impact Drill is a high-performance household tool suitable for various daily repair and assembly tasks. Equipped with…

Optimal Grinding Wheels for Faster Metal Grinding with Angle Grinders 1. Best Grinding Wheels for Fast Metal Removal For high-speed metal grinding, the top choices are: Wheel Type Best For…

Can an Angle Grinder Cut Bolts? Safety & Techniques 1. Can an Angle Grinder Cut Bolts? ✅ Yes, angle grinders can cut bolts, but with strict safety precautions. Best for:…

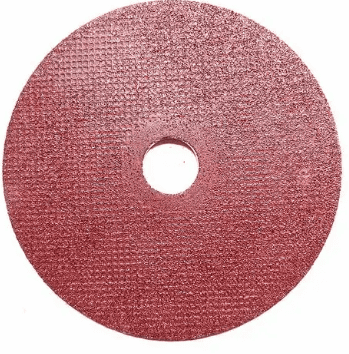

What are the specifications and models of cutting discs? How to maintain a cutting machine? Cutting discs belong to the category of grinding wheels. They are thin sheets made of…

Cutting Wheels: Classification and Applications Cutting wheels belong to the abrasive wheel category, consisting of abrasive grains and resin bonds to form thin discs for cutting ordinary steel, stainless steel,…

Types of Metal Cutting Discs Metal cutting discs are made from different materials, each with its own applicable scope and cutting performance. Common types of metal cutting discs include: How…

Detailed Translation and Extension: Tools Utilizing Cutting Blades The primary tools that employ cutting blades include angle grinders, electric drills, and cutting machines. Types of Cutting Blades and Their Applications…

Comprehensive Guide to Cutting Tools: Classification, Applications and Technological Developments Introduction Cutting tools represent one of humanity’s oldest technological innovations, evolving from primitive stone tools to today’s computer-controlled systems. This…