How do l know if a drill bit is for concrete?

How to Identify Whether a Drill Bit is for Concrete or Wood

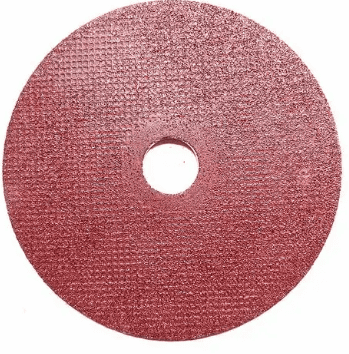

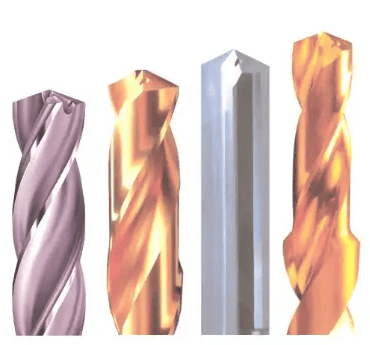

1. Bit Shape

- Concrete Bits:

- Thicker (usually >5mm diameter)

- Fluted design to eject debris efficiently.

- Wood Bits:

- Thinner (<5mm diameter)

- Sharp, pointed tip for clean entry into wood.

2. Material

- Concrete Bits:

- Made of hardened steel or tungsten carbide for durability.

- Wood Bits:

- Often high-speed steel (HSS) or carbon steel with sharp edges.

- Tungsten carbide tips are rare (used for abrasive woods).

3. Performance Feedback

- Wood: Low resistance, smooth drilling.

- Concrete: High resistance, heavy feedback, slower progress.

Conclusion: Check shape, material, and drilling feel to avoid misuse. Always verify specifications before purchase.

Guide to Diamond Core Bits for Concrete

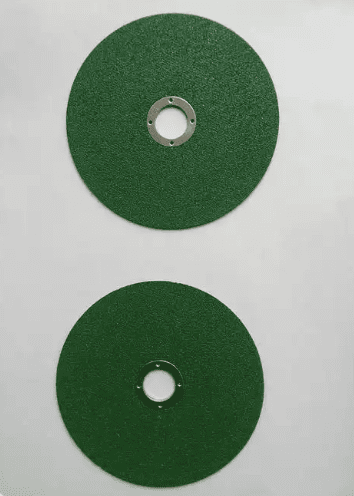

1. Material & Size

- Materials: Tungsten steel, HSS, carbide.

- Size: Match bit diameter/depth to your project needs.

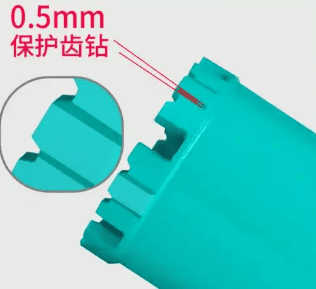

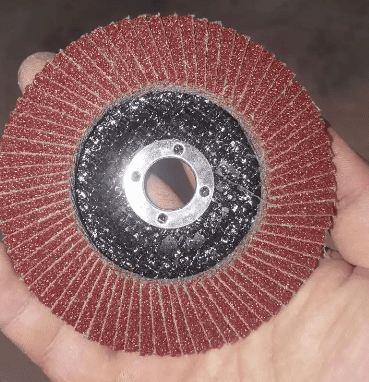

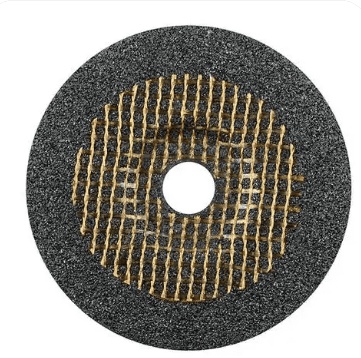

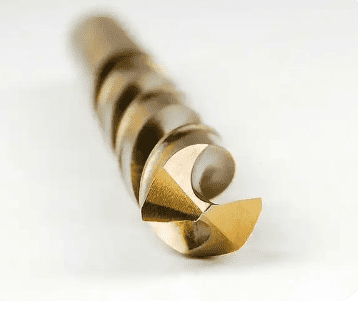

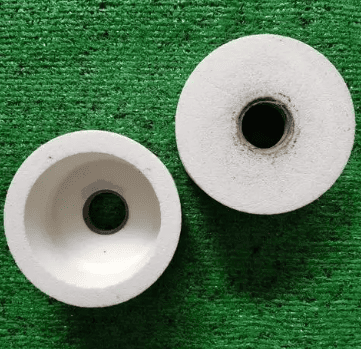

2. Tooth Design

- Straight teeth: Hard materials (concrete, brick).

- Spiral teeth: Soft materials (wood, drywall).

3. Usage Tips

✔ Mark drill points first.

✔ Keep the bit perpendicular to the surface.

✔ Start slow, then increase speed.

✔ Use water cooling to prevent overheating.

Best Drill Bits for Concrete Walls

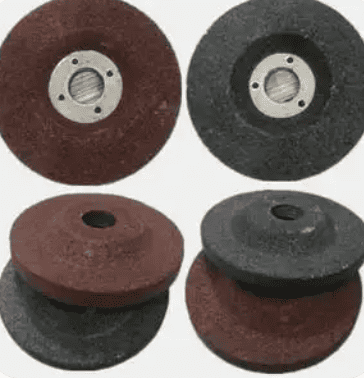

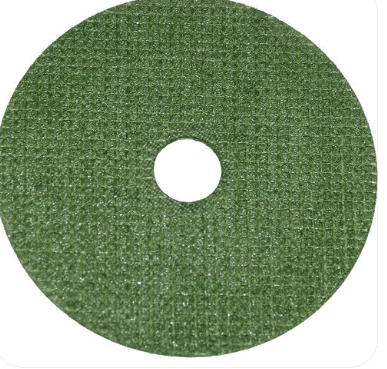

1. Tungsten Carbide Bits

- For small holes (<10mm).

- Hard alloy resists wear.

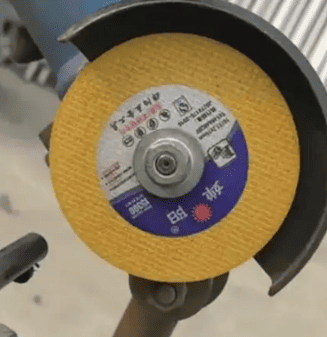

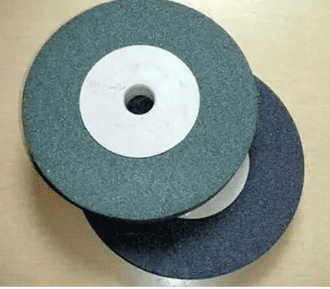

2. Hammer Drill Bits

- Rotary + impact action for faster drilling.

- Best for medium-large holes (with hammer drills).

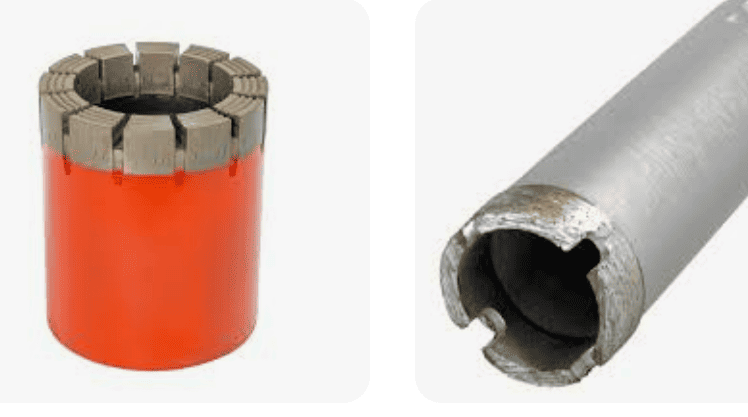

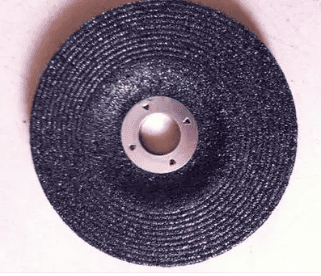

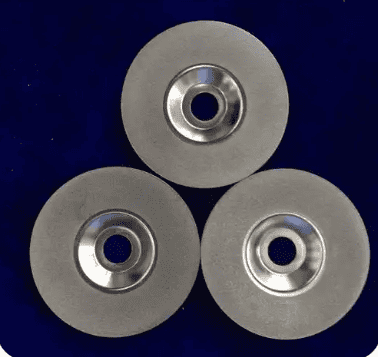

3. Diamond Core Bits

- Premium choice for precision/large holes.

- Cuts through rebar effortlessly.

Selection Factors:

- Hole size/depth

- Tool compatibility (hammer drill vs. rotary)

- Worksite conditions (dust, debris)

Pro Tip: For reinforced concrete, diamond bits outperform carbide.

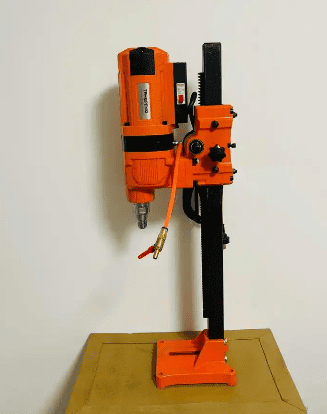

Drilling Concrete: Step-by-Step

- Tool Check: Ensure drill/hammer mode is enabled.

- Bit Installation: Secure a carbide-tipped masonry bit.

- Mark & Start: Begin at low speed, then ramp up.

- Cooling: Spray water to extend bit life.

- Safety: Wear goggles, gloves, and a mask.

Avoid:

❌ Using wood/metal bits on concrete.

❌ Excessive force (let the tool do the work).

Concrete Bit Size Guide

| Hole Size | Recommended Bit |

|---|---|

| <10mm | Tungsten carbide masonry |

| 10–25mm | SDS-plus hammer bit |

| >25mm | Diamond core bit |

Note: For deep holes (>100mm), use extension rods.

Final Recommendations

- DIY Small Holes: Carbide-tipped masonry bit + hammer drill.

- Professional Use: Diamond core bit for rebar-heavy walls.

- Safety First: Always use ground-fault protection and secure workpieces.

This guide ensures fast, clean, and safe concrete drilling! 🔨

Friendly Links: You may also interest in: Herb grinder machine, Portable EV Charger with battery, servo filling machine, aluminum plastic film.

One Comment