Will a core bit cut through rebar?

Can a core drill penetrate rebar?

Indeed, a hollow core drill bit can be used to drill through reinforced concrete with rebar.

1. Can a core drill penetrate rebar?

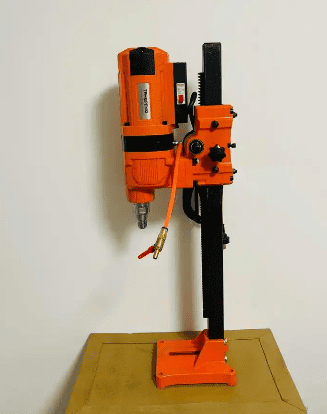

A core drill is a tool capable of drilling through both concrete and rebar, but it cannot penetrate rebar in all situations. Since rebar is a relatively hard material, the drill bit must apply sufficient pressure to penetrate the rebar and continue drilling downward. Therefore, when using a core drill, it is essential to select the appropriate drill bit, adjust the rotation speed, and apply suitable pressure to successfully penetrate the rebar.

2. What should be considered when using a core drill?

a. Selecting the right drill bit

Different materials require different drill bits. When using a core drill, choose the appropriate bit based on the material you are drilling. Additionally, drill bits of different diameters correspond to different hole sizes, so select the bit according to the required aperture.

b. Applying proper pressure

Applying the right amount of pressure helps the drill bit penetrate the rebar and concrete more effectively while controlling the drilling progress. However, excessive pressure may damage the bit or shorten its lifespan. Therefore, moderate pressure should be applied to avoid equipment damage.

c. Controlling rotation speed

An appropriate rotation speed improves drilling efficiency, but speeds that are too fast or too slow can affect performance. Thus, select the right speed based on the required hole size and the material being drilled.

My family works in the construction industry, and nowadays, walls in buildings contain rebar. We use a water core drill bit that performs exceptionally well, drilling quickly and efficiently, even when encountering rebar.

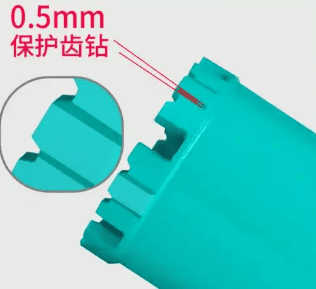

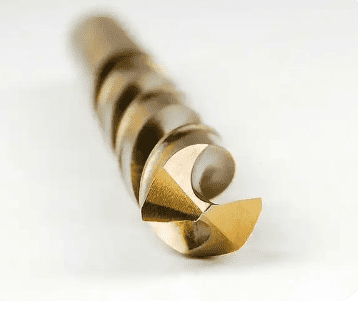

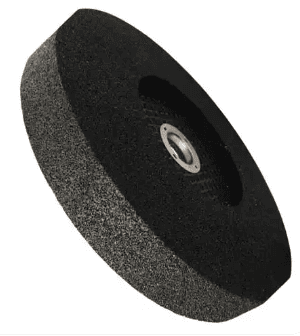

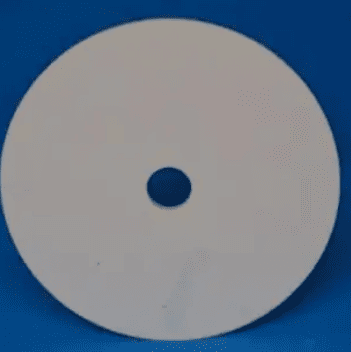

This water core drill bit boasts outstanding performance, utilizing advanced technology and high-quality materials to effortlessly drill through rebar-dense concrete structures. It features an efficient cooling system that reduces heat generation during drilling, protecting the rebar from damage. Additionally, this drill bit is highly durable, maintaining excellent performance in various complex construction environments.

When using this water core drill bit for renovation and repair work, we found that it drills quickly and with high precision, meeting diverse construction needs. Moreover, it is simple and convenient to operate, significantly saving time and improving efficiency. Even when drilling through reinforced concrete, it handles the task effortlessly, ensuring smooth progress.

In summary, this hollow water core drill bit is a highly practical tool, capable of easily drilling through rebar-dense concrete structures with remarkable efficiency and durability. If you’re looking for a water core drill bit that can handle complex construction environments, this one is undoubtedly an excellent choice.

To ensure optimal drilling results, we take additional measures when using this drill bit, such as applying appropriate coolants and lubricants to reduce heat and wear during drilling. We also regularly inspect and maintain the drill bit to keep it in top condition. These measures ensure safety and reliability during construction.

3. Precautions when drilling rebar with a core drill

When using a core drill to penetrate rebar, it is crucial to select the right drill bit, apply proper pressure, and control the rotation speed to successfully drill through the rebar and continue downward. Additionally, the following points should be noted:

- Replace the drill bit promptly if it shows significant wear.

- Ensure equipment stability and drilling direction during the process.

- Clean the hole of debris immediately after drilling.

In conclusion, when using a core drill, choose the appropriate method and precautions based on the specific situation to ensure successful drilling and protect the equipment. Avoid reckless actions during operation.

Introduction to drill bits specialized for rebar and their applications

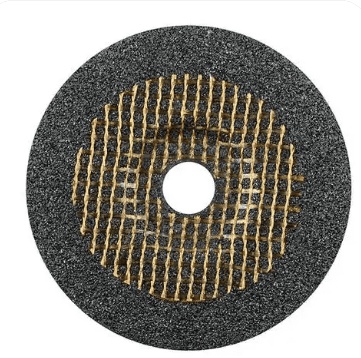

Drill bits specialized for rebar mainly include twist drills, core drills, and cutting drills, each suited for different construction scenarios. When purchasing, pay attention to the bit’s material, diameter, and length, and follow standardized operating procedures to ensure safety and effectiveness.

In construction, rebar is an essential material. When working with rebar, selecting the right drill bit is critical. This article introduces the types, features, applications, and purchasing advice for drill bits specialized for rebar, helping readers better understand and use these tools.

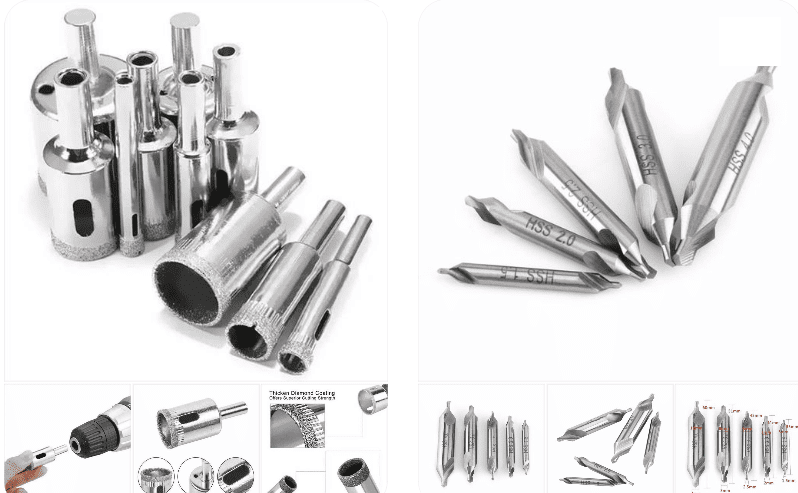

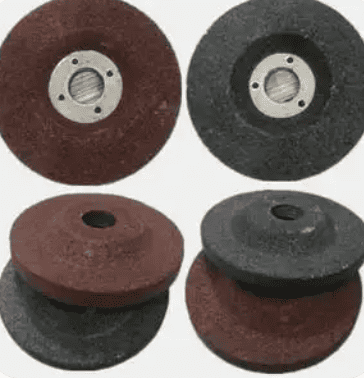

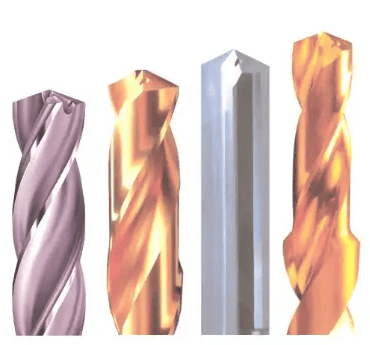

1. Types of drill bits specialized for rebar

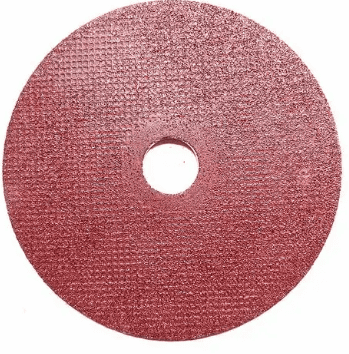

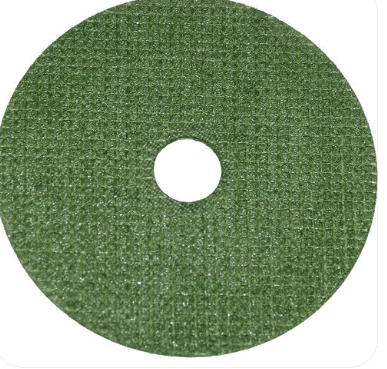

a. Twist drills: The most common type, suitable for smaller-diameter holes. They feature multiple cutting edges and lower cutting force, making them ideal for drilling hard rebar.

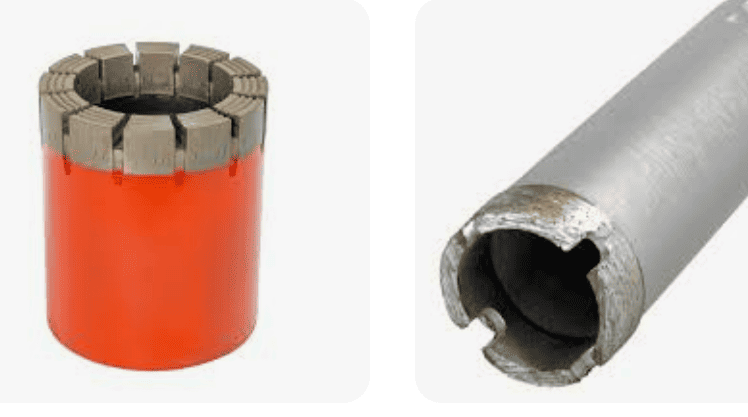

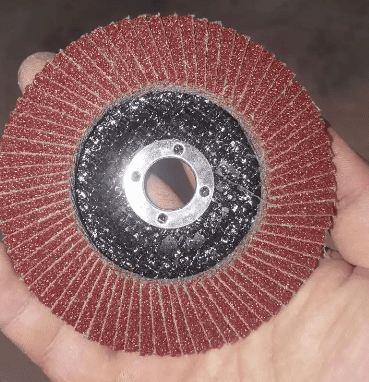

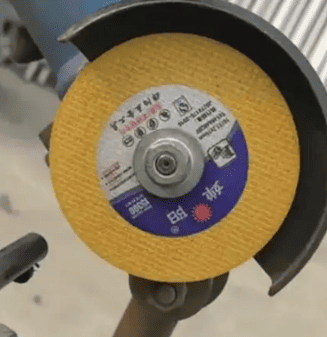

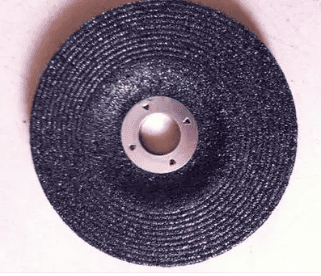

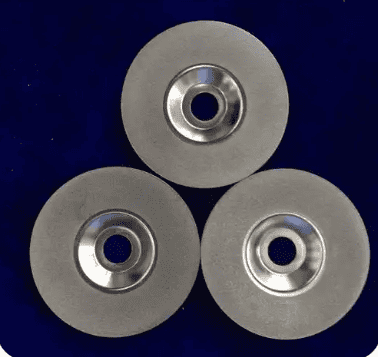

b. Core drills: Used for larger-diameter holes. Their hollow design allows quick removal of cuttings, improving efficiency.

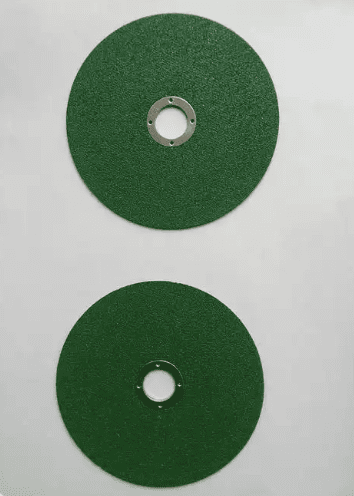

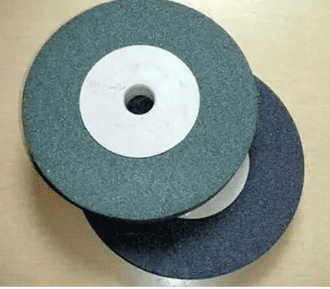

c. Cutting drills: Primarily for cutting rebar but can also drill holes. They have fewer cutting edges and higher cutting force, suitable for softer rebar or cutting tasks.

2. Applications of drill bits specialized for rebar

a. Twist drills: Ideal for drilling small holes in hard rebar, such as fixing pipes or wires in concrete walls or slabs.

b. Core drills: Suitable for larger holes in thick rebar or steel plates, such as installing heavy equipment or supports.

c. Cutting drills: Used for quick cutting or drilling in softer rebar, such as processing scrap rebar or making rebar mesh.

3. Purchasing recommendations for rebar drill bits

a. Material: Choose high-speed steel or carbide bits for better durability and lifespan.

b. Diameter and length: Select based on construction needs to ensure quality and efficiency.

c. Brand and quality: Opt for reputable brands and reliable products to guarantee performance.

4. Usage precautions for rebar drill bits

a. Inspect the bit for wear or cracks before use.

b. Maintain proper drilling speed and feed rate to avoid damage or poor hole quality.

c. Drill vertically to prevent skewed holes.

d. Clean cuttings promptly after drilling to keep the bit sharp and in good condition.

In summary, selecting the right drill bit for rebar is crucial for construction quality and efficiency. Understanding the types, features, and applications of these bits, along with purchasing and usage tips, can enhance their effectiveness and improve construction outcomes.

You may also interest in other topics: 20kw charging station, Granule filling machine; irregular plastic bag irregular shaped.