Die grinder uses

die grinder uses: How to use the mill, what are the precautions in the use process?Electric mill is also called multi-function electric mill, engraving machine, engraving pen, electric mill. According to the size can be divided into conventional type, small, micro.

The use of the electric mill

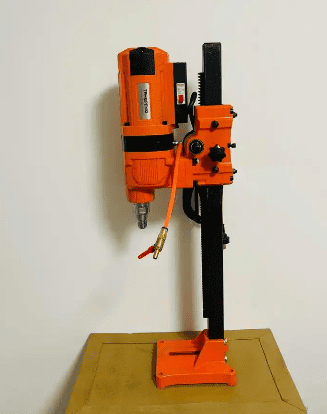

1: The motor of the electric mill uses 220 volts of alternating current, the power is generally 120-250 watts, and the speed can be controlled at 8000-30000 RPM with stepless speed regulation.

2: The soft whip of the electric mill is a hollow soft cable set with a free rotation of the wire rope, the end of the soft whip is connected to a pen-like sleeve, the length of the pen-like sleeve is about 15 cm, the diameter is about 2 cm, the sleeve core is connected by the soft cable and the motor; Because of its small size, the operation is very flexible and convenient.

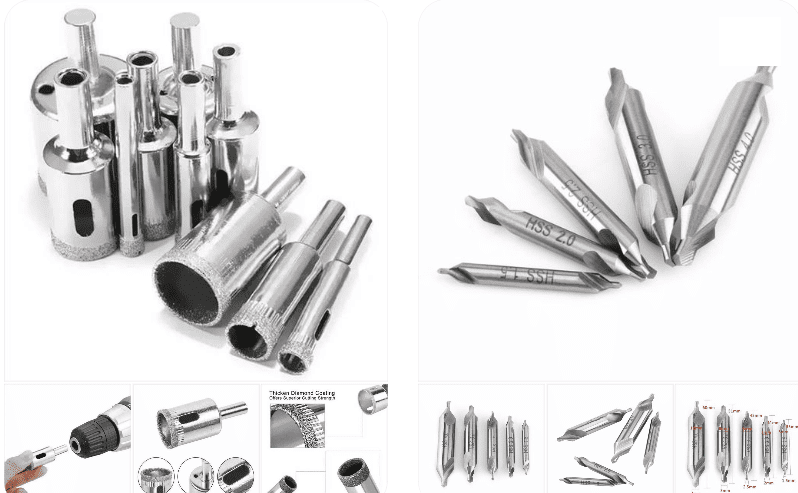

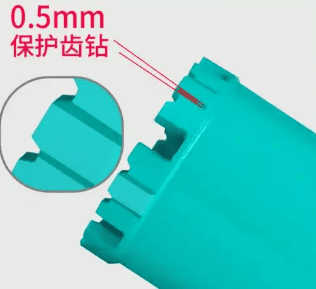

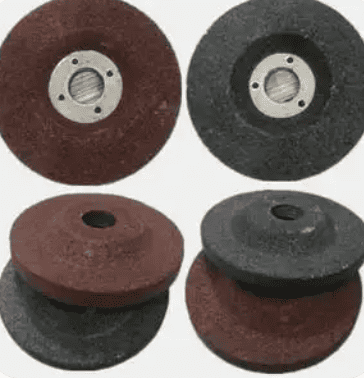

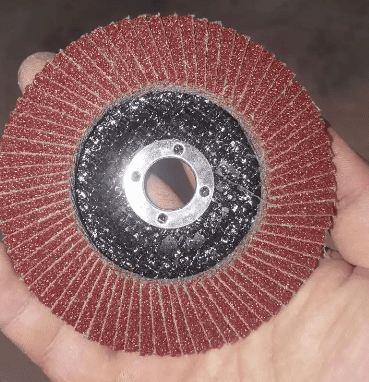

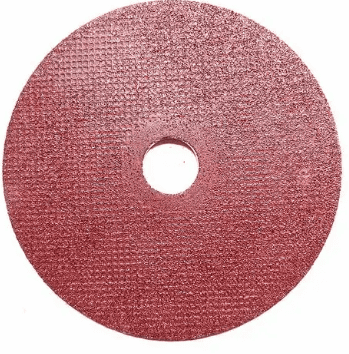

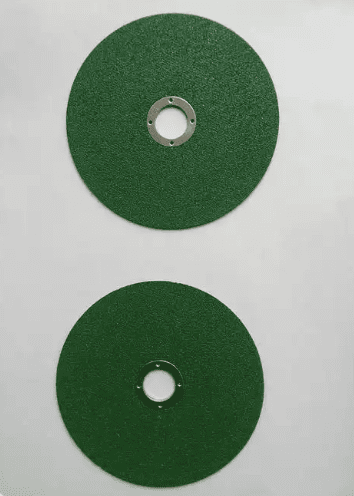

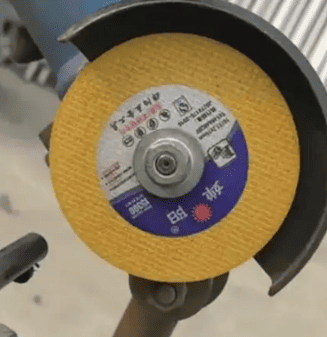

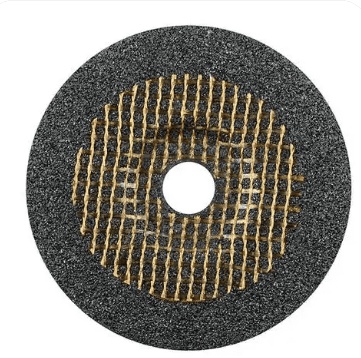

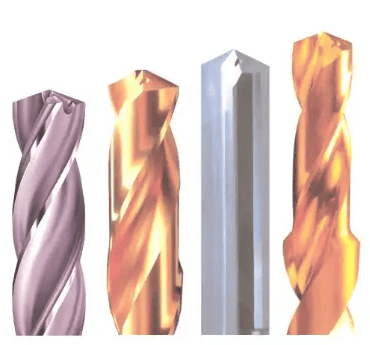

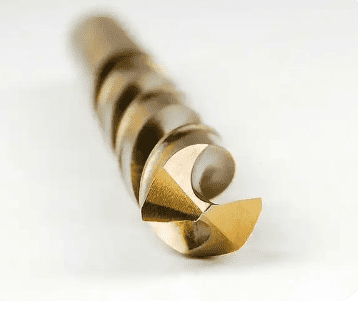

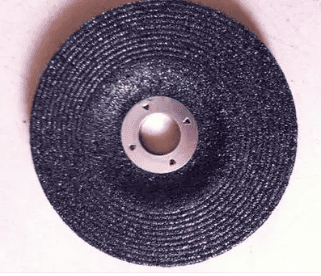

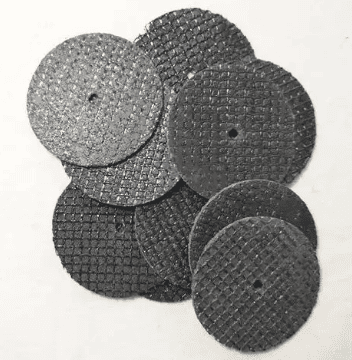

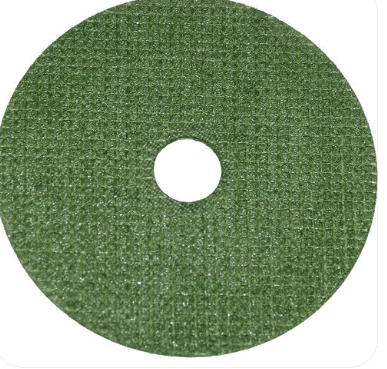

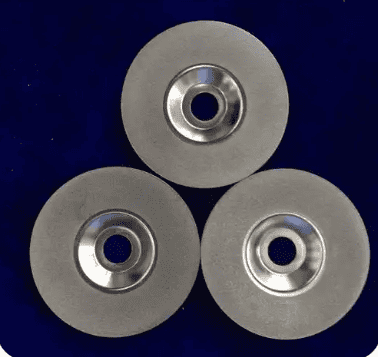

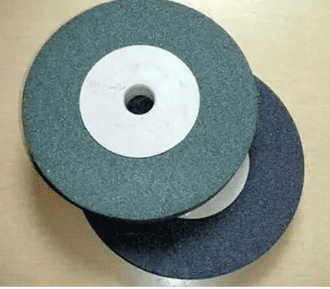

3: accessories for the electric mill; The socket can be installed 0.3-2mm drill bits, in addition to the drill accessories, other accessories, such as cutting pieces, grinding head, polishing etc. are connected by a shaft with a diameter of 2mm. The diameter of the cutting sheet is about 25mm. Due to its small diameter, the cutting direction can be changed at will to make a cut with a pattern. The width of the cut does not exceed 1mm, and the cut is less than 0.7mm thick. Cutting pieces with different materials can cut no The same material, such as iron, aluminum, alloy, wood, plastic, etc. Cutting pieces and carving heads with emery can be used to carve patterns on glass and jade.

4: Micro electric mill: there are three parts of the control box and the handle, the foot speed switch, because its speed is higher than the large electric mill (30,000-50000 RPM to choose from, feeling smooth, almost can not feel the shake, more suitable for fine engraving, seal cutting, polishing and other operations.

The use and maintenance instructions of the electric mill:

1: After the flexible shaft and the electric mill body are connected, do not disassemble frequently unless special circumstances.

2: The mill is running for 15-20 minutes, please stop and cool down.

3: For unfamiliar processing processes or processing materials, please adjust the grinding speed from a low start, especially for plastic plexiglass and other materials that are not resistant to high temperature, but also pay attention to low speed operation, otherwise it will dissolve the material and damage the grinding head.

4: Please test on waste materials for the first time to accumulate experience.

Safety precautions for the use of electric mill

1: When installing the flexible shaft or replacing the grinding head, be sure to unplug the power plug!

2: The chuck of the flexible shaft and the fuselage, the chuck of the flexible shaft and the grinding head, be sure to lock with a small wrench.

3: When the mill is connected to the power supply, the power switch must be in the OFF off state.

4: Before processing, in addition to the workpiece should be fixed firmly, should also be the grinding test turn (no-load), after confirming that there is no abnormal processing operation.

5: Before operation and use, the grinding head should be carefully inspected, and the damaged or cracked grinding head is strictly prohibited.

6: Wear protective goggles when using tools.

7: When the parts are processed. The pressure exerted by the hand on the electric mill should be properly controlled, and excessive force should not be exerted.

8: When using the cutting sheet processing, be sure to ensure that the personnel deviate from the tangent direction of the cutting sheet to prevent the cutting sheet from flyingIndustrial News.

We OEM your brand and also color box, printed bags, outer box packages.

You can also refer to following links if you are interest in following information:

Level of EV Charger 4 sides sealing bag customize