Are diamond blades safe?

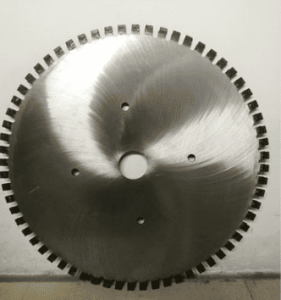

The safety performance of diamond saw blades is a quality issue that cannot be overlooked, as “tooth loss” caused by production or usage reasons directly affects the blade’s performance and the operator’s personal safety. There are risks associated with using diamond saw blade tools in industrial production. Out of concern for life protection and safety, their security has garnered increasing attention from manufacturers and users. Although national and industry standards have not yet established clear and specific regulations regarding the safety performance of diamond saw blades, relevant international standards—such as the new EN13236 standard—and cases of product recalls abroad due to safety issues can be referenced. By improving production processes and enhancing monitoring methods, the safety performance of diamond saw blades can be ensured.

Factors Affecting the Safety Performance of Diamond Saw Blades

- The outer edge of the blade body and tooth area are not clean, leading to weak welding bonds.

- Poor control of sintering process parameters, low sintering temperature (“under-sintering”) resulting in weak bonding, low matrix strength, and brittleness.

Measures to Improve the Safety Performance of Diamond Saw Blades

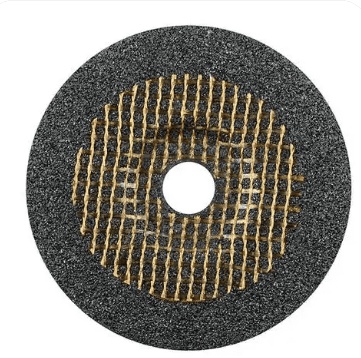

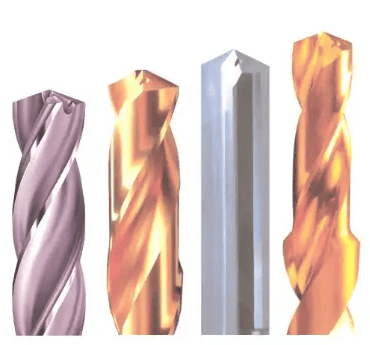

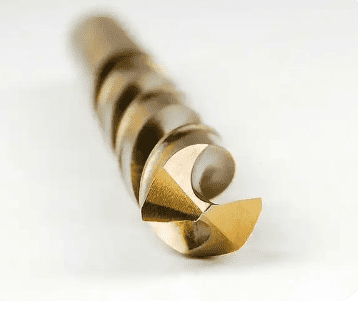

- Optimize design. Use raw material powder with low oxygen content; modify the outer edge shape of the blade body to a “dovetail” design to enhance the bonding strength between the matrix and the blade body.

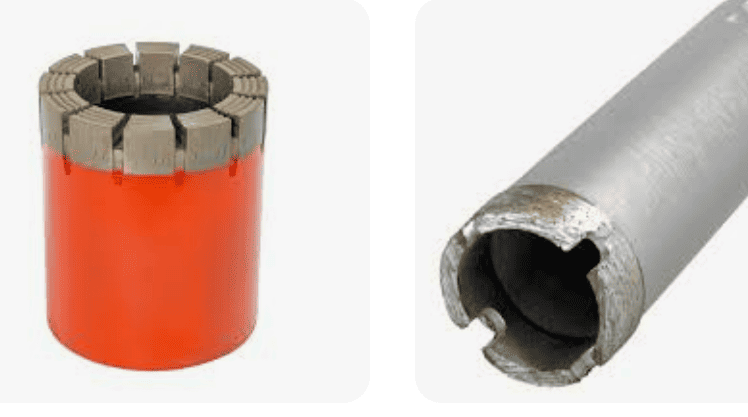

- Optimize processes. Apply a “copper plating” process to the blade teeth; adopt a cold-pressing and hot-sintering process; implement a hot-pressing and fusion welding process (i.e., laser welding). Traditional high-frequency welding often results in insufficient bond strength (especially at high temperatures), leading to accidents such as segment detachment during cutting, which compromises the blade’s safety and reliability. In contrast, laser welding uses a focused laser beam as the energy source, employing deep fusion welding to melt the segment’s transition layer and the blade body, forming a strong weld. Even when used without cooling water for the saw blade or drill bit, it ensures high welding strength and operational safety.

Proper Usage Guide for Diamond Saw Blades

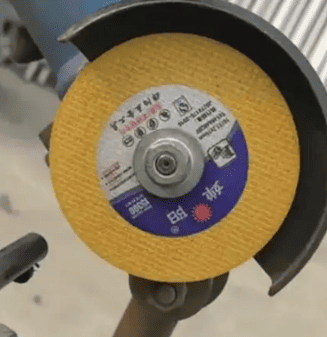

The operator’s consistent use of diamond saw blades, a highly efficient tool in contemporary cutting processes, directly affects their performance and lifespan. Strict adherence to technical specifications is necessary at every stage, from equipment matching to routine maintenance. Any oversight could result in safety incidents or decreased cutting efficiency. This article systematically explains the key operational points for diamond saw blades, from installation to storage, helping users master the correct usage methods.

I. Critical Control Points in Installation Preparation

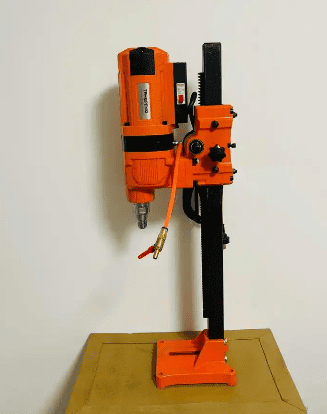

Before installing a diamond saw blade, thorough equipment compatibility checks must be conducted. Blades of different diameters have specific requirements for cutter power and speed:

- Blades under 150 mm in diameter require a 1–1.5 kW power cutter with a speed range of 7,255–14,500 rpm.

- Medium-sized blades (150–230 mm) need 1.5–3 kW power support, with speeds adjusted to 4,000–11,000 rpm.

- Large stone-cutting blades demand 15+ HP motors, maintaining a linear speed of 20–60 m/s.

These parameters are not arbitrary—insufficient power leads to weak cutting, while excessive speed may cause segment detachment. In practice, there have been cases where operators ignored matching parameters, such as using a 3 kW cutter to drive a 300 mm blade, resulting in spindle overheating and deformation. This underscores the importance of proper equipment matching.

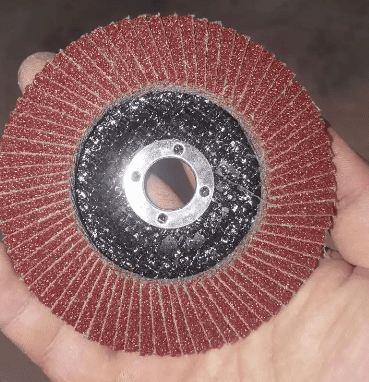

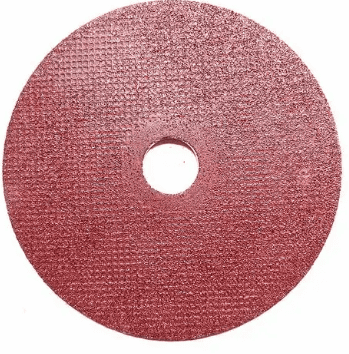

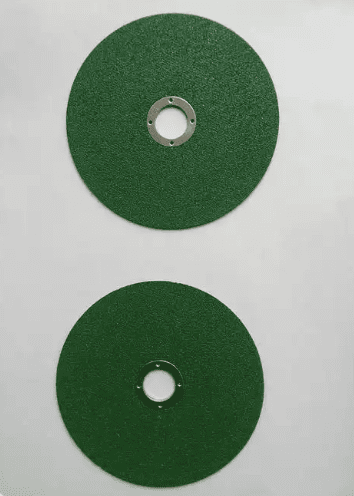

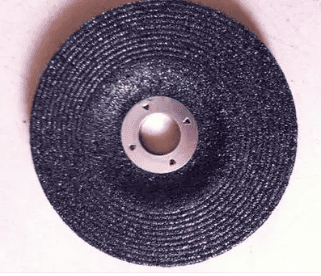

Installation details are equally critical. Before mounting, inspect the blade for visible deformations or cracks. The diamond segments should be uniformly arranged like soldiers in formation, with even abrasive grain distribution. During installation, ensure the arrow mark aligns precisely with the cutter’s rotation direction—similar to directional car tires, incorrect alignment can reduce cutting efficiency by over 30%.

Flange plate precision is also vital: the mounting hole and spindle tolerance should stay within 0.1 mm (about two hair strands’ width). An undersized flange causes blade wobble, while an oversized one increases radial runout. Ideally, the flange diameter should be no less than one-third of the blade diameter. After installation, conduct a 2–3 minute no-load test, where the operator must detect abnormal vibrations by hand, as even minor tremors may indicate installation flaws.

II. Precision Control During Cutting Operations

Initial setup is fundamental to cutting quality. The cooling system is particularly crucial:

- Wet cutting requires continuous coolant spray at ≥0.1 MPa pressure (twice household water pressure).

- Dry cutting must limit continuous operation to ≤3 minutes for a 400 mm blade, as segment temperatures exceeding 700°C can graphitize diamonds, causing failure.

Material fixation must also be standardized. For blocks ≥0.5 m³, anti-corrosion-treated wooden supports should be placed underneath to minimize displacement. Field data from stone-processing plants show that proper fixation improves cutting accuracy by 40%+.

Parameter adjustment is the core of cutting technology. Different materials require tailored settings:

| Material | Linear Speed (m/s) | Feed Rate (m/min) | Cutting Depth (mm) |

|---|---|---|---|

| Marble | 20–35 | 9–12 | 50–100 |

| Granite | 25–35 | 9–12 | 10–20 |

| Hard Quartzite | ≤25 | 6–9 | 3–5 |

These combinations function like herbal prescriptions, requiring fine-tuning based on material hardness and quartz content. A progressive cutting method is recommended: start with a 30 mm depth, then gradually increase after stabilization to avoid impact loads on segments. If material wobbling or blade deceleration occurs, stop immediately—these are early warnings of segment damage or material shift.

III. Establishing a Safety Protection System

Personal protective equipment (PPE) is the operator’s last line of defense:

- Face shields must meet EN166 P-class, resisting high-speed debris.

- Noise-canceling earmuffs (≥36 dB SNR) reduce jet-engine-level noise to conversation level.

- Slip-resistant boots are essential, especially in wet conditions.

Statistics show proper PPE reduces injury risks by 85%. The cutting zone must have ≥1.2 m guardrails, and operators must never stand directly in front of the blade—the primary debris trajectory.

Safety protocols strictly prohibit:

- Using “dead-sounding” blades (indicating internal damage, risking explosion).

- Overspeeding or curved cuts, which induce complex stresses and fractures.

- Cutting metals/ductile materials, as this reduces blade life by 90%+ due to abnormal wear.

IV. Scientific Maintenance & Storage

Routine upkeep extends blade lifespan:

- After cutting, clean residues immediately with a medium-hardness wire brush (like dental cleaning).

- Monthly soak in 5% oxalic acid to dissolve stone powder without corroding the metal base.

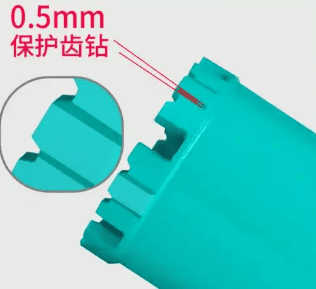

- Check segment height differences every 8 hours—>0.5 mm (five printer papers’ thickness) requires professional reconditioning.

For long-term storage:

- Hang or lay flat in <60% humidity environments on moisture-proof boards.

- Never stack directly on concrete, as this may warp the blade core. Lab tests confirm properly stored blades retain 70%+ better performance after three years.

Conclusion

Following these guidelines typically extends blade life beyond 120% of rated value while ensuring stable cutting quality. Crucially, these standards form an interconnected system—neglecting any aspect compromises overall results. Operators must internalize these practices to fully harness diamond blades’ potential.