Can you cut cast iron with a diamond blade?

Diamond saw blades can cut iron, but they are not suitable for cutting ferrous materials.

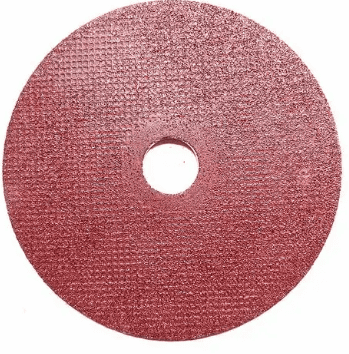

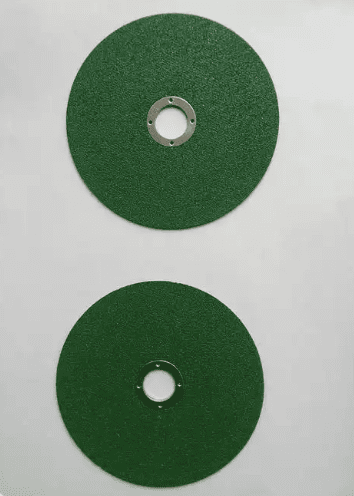

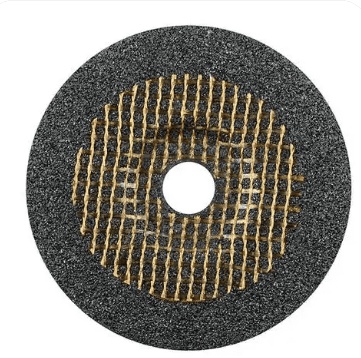

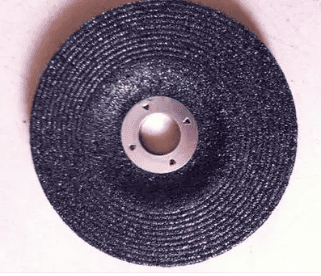

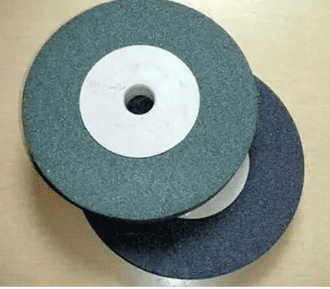

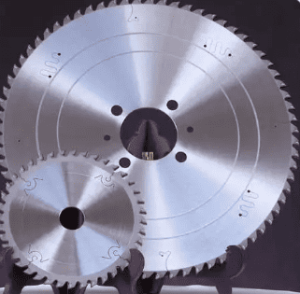

When discussing whether diamond saw blades are suitable for cutting ferrous materials, we must first clarify their design purpose and characteristics. Diamond saw blades, known for their extreme hardness, excel at cutting non-metallic hard materials such as stone, ceramics, and glass. However, the situation is quite different when it comes to ferrous materials. Iron not only has high hardness but also generates significant heat during cutting, posing a serious challenge to diamond saw blades. The heat accelerates blade wear and can even damage the cutting surface. Additionally, iron’s tendency to rust may cause further harm to the blade. Therefore, diamond saw blades are not suitable for cutting ferrous materials. For iron and steel materials, we recommend using metal saw blades, milling cutters, or specialized cutting

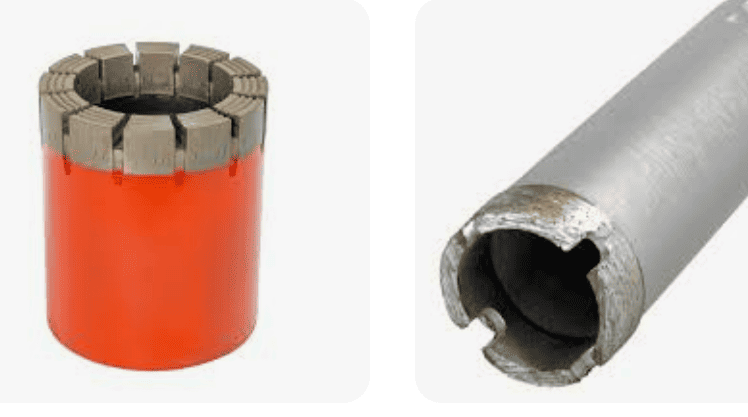

Diamond saw blades can cut iron. However, it should be noted that while diamond saw blades are extremely hard and capable of cutting various materials, including iron, practical applications require consideration of the blade type, specifications, and compatibility with cutting equipment. For example, specialized pile saw blades can be used to cut materials like concrete embedded with steel reinforcement bars.

When using diamond saw blades to cut iron, the following points should also be considered:

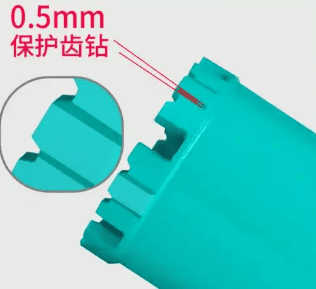

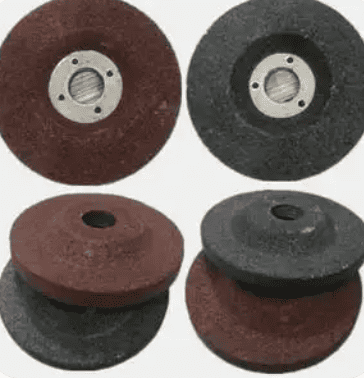

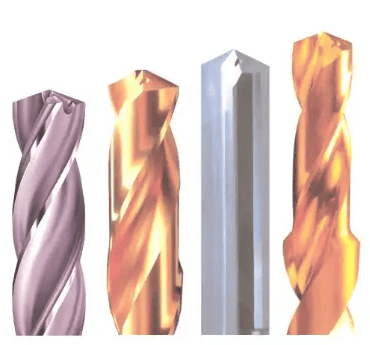

- Select the appropriate saw blade—Ensure that the blade’s hardness, thickness, and tooth configuration are suitable for cutting ferrous materials to improve efficiency and extend blade life.

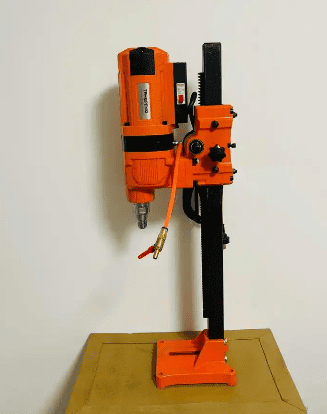

- Maintain proper equipment operation—Ensure that the spindle bearings, clamping plates, and other components of the cutting equipment are functioning correctly to avoid poor cutting performance or blade damage due to equipment failure.

- Monitor vibrations during cutting—If vibrations occur during cutting, it may indicate issues with the equipment or blade. In such cases, stop cutting immediately and troubleshoot the problem.

- Sharpen the blade correctly—As the blade wears over time, regular sharpening is necessary to maintain its cutting performance. During sharpening, maintain the original blade angle to avoid cutting problems caused by improper sharpening.

The Fastest Method for Cutting Cast Iron

1. What is the fastest way to cut cast iron?

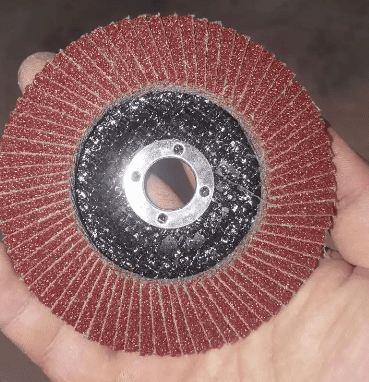

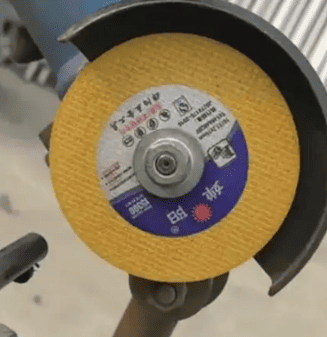

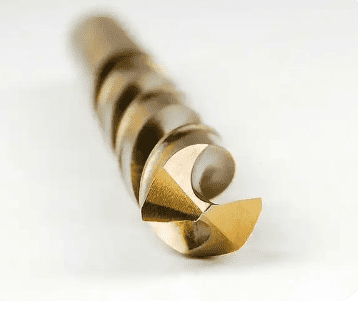

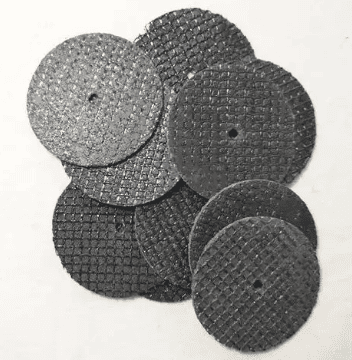

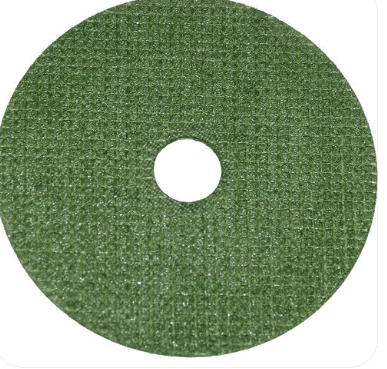

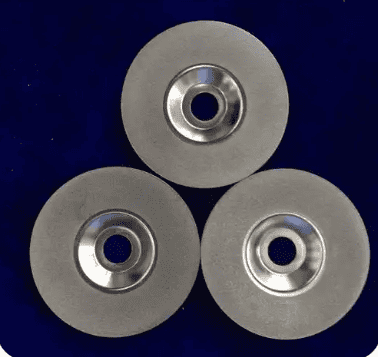

Since cast iron is a very hard metal, oxy-acetylene torch cutting and plasma cutting are popular cutting techniques. However, using a diamond cutting disc is the quickest method. Diamond cutting discs are perfect for swiftly cutting cast iron because they can effectively cut through hard, thick materials. High-speed steel blades are also a good choice because they make cutting cast iron quick and simple.

2. How to prepare and operate cutting tools?

- Before using a diamond cutting disc to cut cast iron, use a hammer or other tool to notch the cast iron to ensure smooth cutting.

- When operating a diamond cutter, install the cutting disc properly and adjust the cutting depth accordingly.

- Always prioritize safety—wear protective gear and follow the safety guidelines in the operation manual.

3. How to prevent issues when cutting cast iron?

- Ensure the cast iron is placed flat and securely fixed on the workbench to guarantee safe cutting.

- When using high-speed steel blades, select the appropriate blade type based on the model, avoiding old or excessively worn blades.

- Maintain smooth blade rotation during cutting, avoiding excessive force or lateral pressure.

In conclusion, the fastest way to cut cast iron is by using diamond or high-speed steel blades. Before using any cutting tool, proper preparation and focused attention are essential to ensure a safe and smooth cutting process.