What is the alternative to core drilling?

Can Hollow Drills and Twist Drills Replace Each Other?

Due to their different structures and usage methods, hollow drills and twist drills cannot fully replace each other. During machining, the appropriate cutting tool must be selected based on actual needs. For conventional drilling materials, twist drills can perform well. However, for difficult-to-drill materials such as ceramics, hollow drills are the more suitable choice.

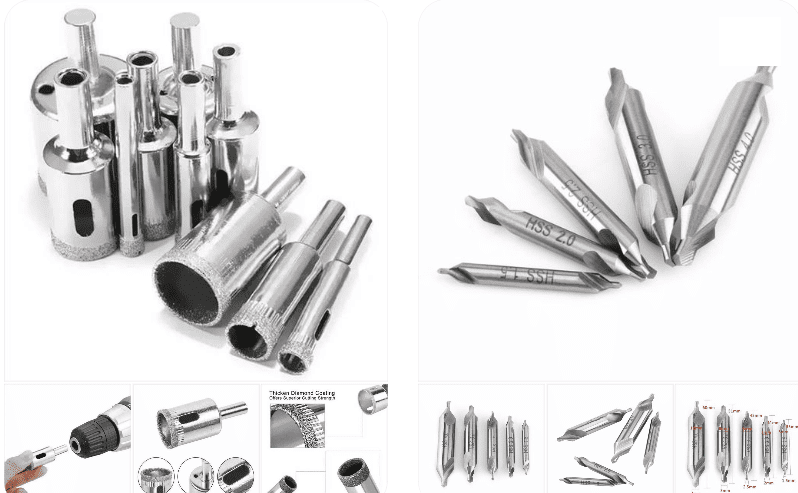

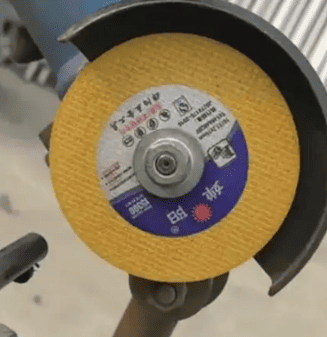

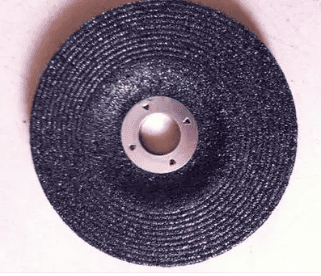

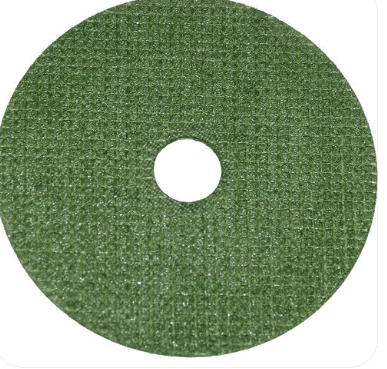

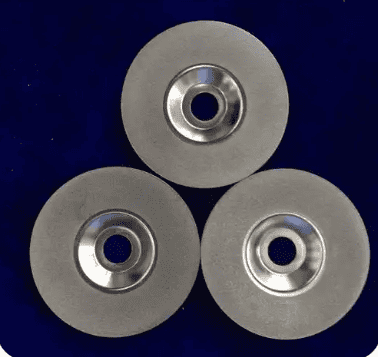

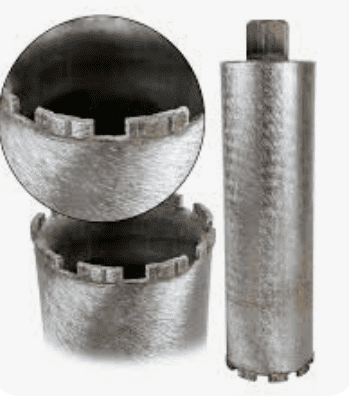

Hollow Drills

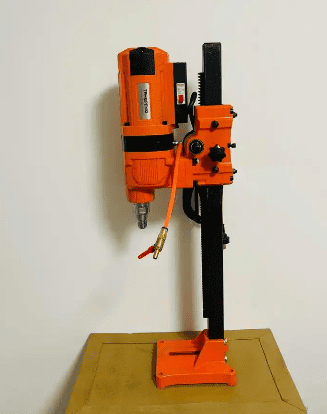

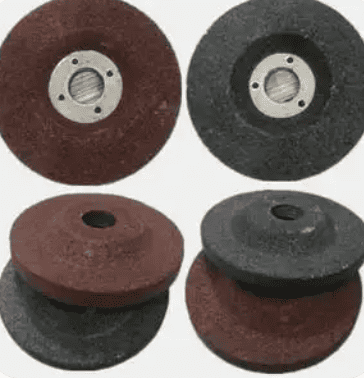

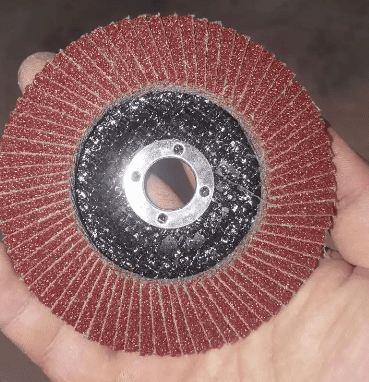

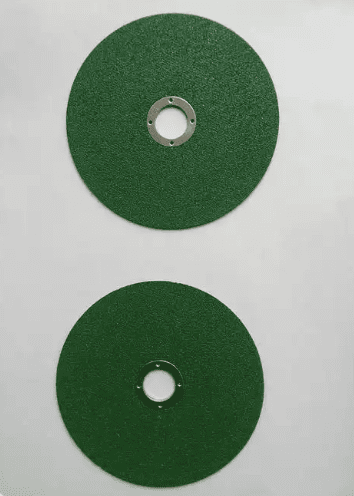

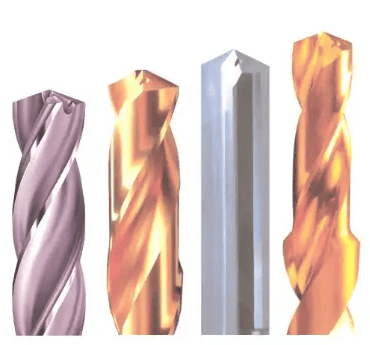

A hollow drill is an industrial drilling tool that removes material through a multi-blade annular cutting structure, also known as a core drill bit, steel plate drill bit, or hole saw [1-2]. Based on material, they are mainly divided into two categories: high-speed steel (HSS) and carbide. HSS drill bits are the primary choice due to their stability and regrindability, while carbide drill bits offer higher cutting speeds. When used with magnetic drills, hollow drills can achieve 8-10 times the efficiency of ordinary drill bits, completing a 40mm diameter hole in a 30mm steel plate in just 25 seconds .

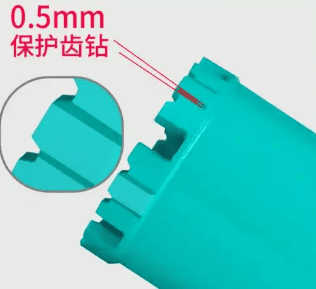

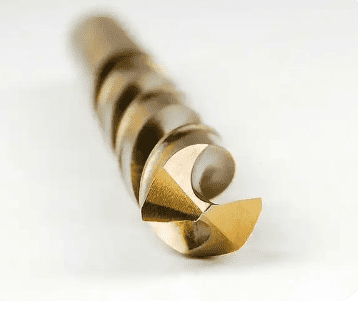

In industries such as steel structure engineering, rail transportation, and shipbuilding, hollow drills can process holes with diameters ranging from 12-150mm and depths of 25-200mm. Their core technology lies in a three-blade combined cutter design, where the outer, middle, and inner blades share the cutting load, working in conjunction with a spring ejector for automatic chip removal. Mainstream products are now equipped with TiAlN coating technology, significantly enhancing blade wear resistance.

Differences Between Hollow Drills and Twist Drills

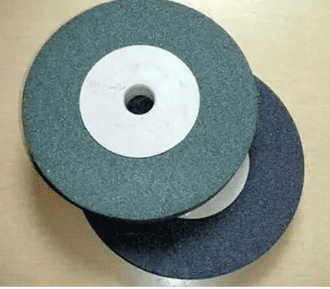

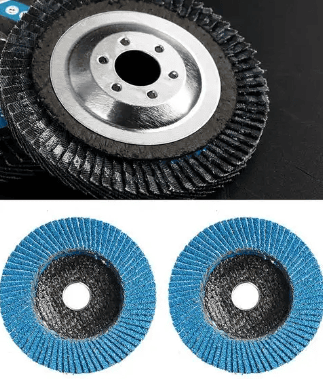

Both hollow drills and twist drills are metal-cutting tools with similar purposes but different structures and machining methods.

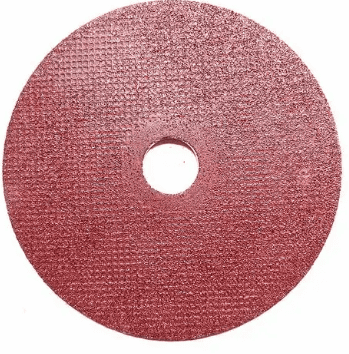

A twist drill, also known as a spiral drill, features a helical groove pattern. The drill bit is solid, but the spiral grooves expel chips from the hole, serving a chip-clearing function. Twist drills are suitable for drilling materials such as steel, stainless steel, copper, and aluminum.

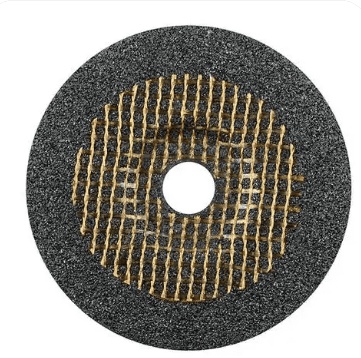

In contrast, the structure of a hollow drill is relatively simple, consisting of a cutting tool and a hollow tube. The hollow tube provides cooling and chip removal, while the cutting tool removes material from the hole wall. Due to their excellent heat dissipation and chip-clearing capabilities, hollow drills are suitable for processing hard-to-cut materials such as ceramics, glass, and rock.

Advantages and Disadvantages of Each

Twist drills are compact, easy to use, and suitable for a variety of materials. However, their solid structure may cause heat-affected zones or scorching on the hole wall, and their helical grooves make the cutting edges relatively fragile. Hollow drills, on the other hand, employ external lubrication and cooling water, increasing the cutting area and heat dissipation, reducing tool surface temperature, and effectively avoiding heat damage and scorching. However, hollow drills are more complex to use, requiring attention to water supply and sealing.

Choosing the right cutting tool can significantly improve machining efficiency and quality, avoiding waste and unnecessary work. This article aims to help readers better understand and select between hollow drills and twist drills.

Can Hollow Drills Replace Ordinary Drill Bits?

Hollow drills and ordinary drill bits serve different purposes and cannot fully replace each other. The appropriate tool should be selected based on specific circumstances.

- Differences Between Hollow Drills and Ordinary Drill Bits

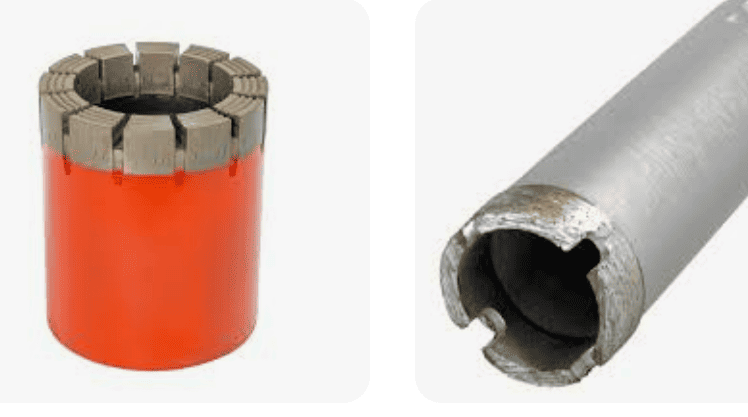

Hollow drills are hollow inside, designed for dynamic fluid handling or continuous rod processing. They are typically used for sampling, collecting underground rock, soil, and water samples. Ordinary drill bits are solid, simply drilling through material. Compared to ordinary drill bits, hollow drills offer greater penetration, higher efficiency, more precise sampling, and more accurate experimental data. - Usage Scenarios

Hollow drills are widely used in geological exploration, mineral prospecting, environmental monitoring, groundwater hydrology, and various scientific research fields, serving as effective tools for collecting rock, soil, and water samples. Ordinary drill bits are commonly used in construction projects, installing nails, rivets, and expansion screws—essentially for drilling holes in materials. - Can They Replace Each Other?

Although both are drilling tools, their applications differ, making full replacement impossible. Hollow drills are suitable for sampling rock, soil, and water, while ordinary drill bits are used for drilling holes in construction or fastening materials and cannot collect samples. For simply drilling larger holes, ordinary drill bits are the best choice. For collecting samples, professional hollow drills should be used. - Conclusion

Hollow drills and ordinary drill bits are both drilling tools but serve different purposes. Hollow drills are used for sampling in geology, hydrology, and environmental science, while ordinary drill bits are for construction and fastening applications. Therefore, the choice should be made based on specific needs.

Friend Links: you may also interest in, click if you want: 7KW EV Charger; rotary filling machine; aluminum plastic film.