Will a core drill go through rock?

Hollow drills can penetrate rocks, but their effectiveness depends on the rock type, drill bit material, and construction conditions.

I. Can Hollow Drill Bits Drill Granite?

Granite is a very hard rock containing a high proportion of hard minerals such as quartz and feldspar. Therefore, when drilling granite, suitable drill bits and techniques must be used to achieve the desired results.

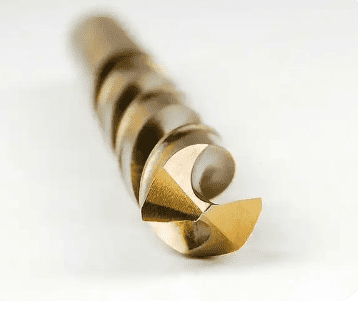

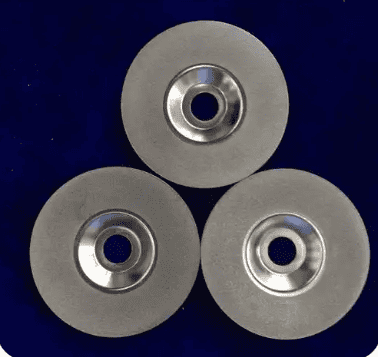

Hollow drill bits are commonly used drilling tools. Their structure allows for the circulation of fluid in and out of the drill rod and bit, enabling control over side leakage during drilling. The advantages of hollow drill bits include higher drilling efficiency and the ability to drill deeper holes. However, their applicability for granite drilling still requires some improvement.

Below is a detailed analysis:

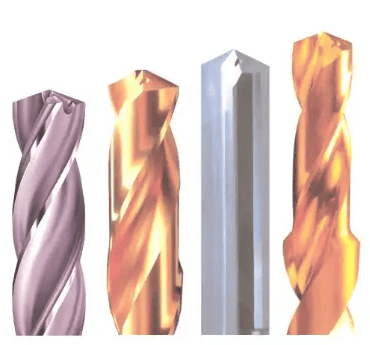

Drill Bit Characteristics

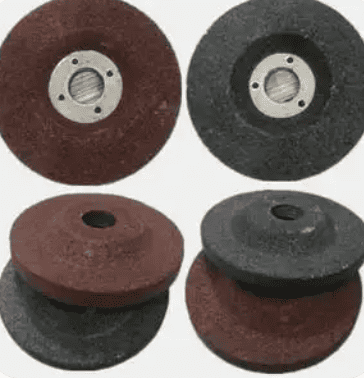

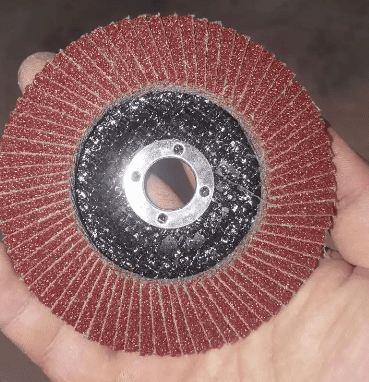

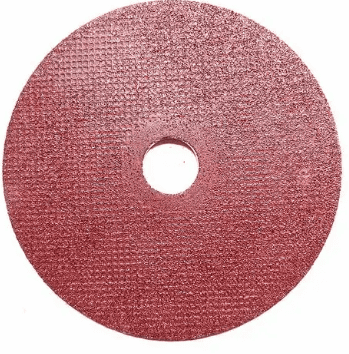

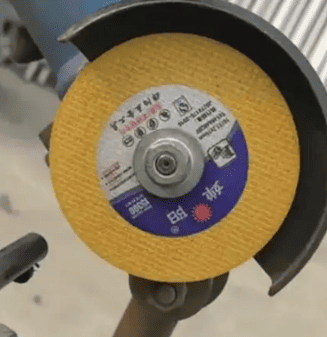

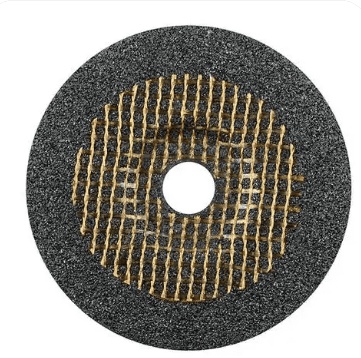

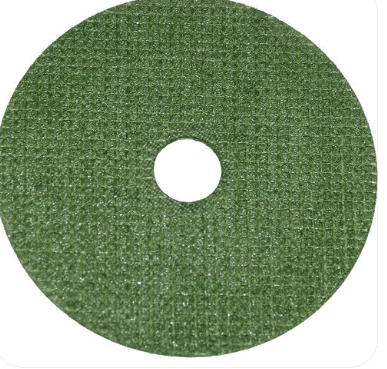

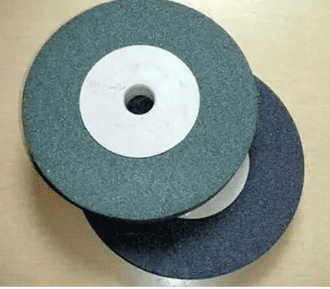

Hollow drills use a multi-blade annular cutting structure, where the outer, middle, and inner blades share the cutting load. They are equipped with an automatic chip removal system, capable of completing a 40mm diameter hole in a 30mm steel plate within 25 seconds. High-speed steel bits offer good stability and regrindability, while carbide bits are more suitable for high-hardness materials.

Applicable Scenarios

In fields such as rail transit and shipbuilding, hollow drills have successfully processed holes with diameters of 12–150mm and depths of 25–200mm. However, due to the significant variation in rock hardness (e.g., limestone is relatively soft, while granite is extremely hard), the type of drill bit and parameters must be selected based on the rock formation characteristics.

Construction Recommendations

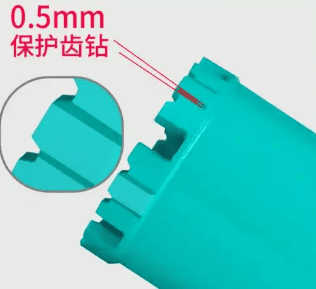

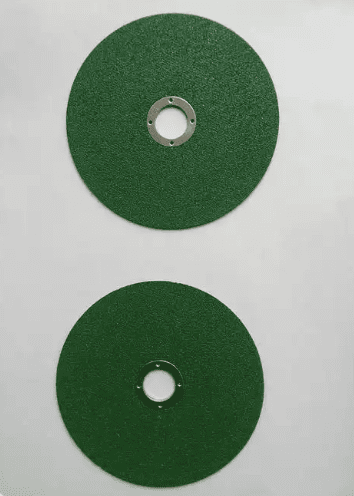

For drilling through hard rock layers (e.g., granite), carbide drill bits are recommended, along with reduced rotation speed. A circulating cooling system should also be used to minimize wear. For extremely hard rock layers (e.g., quartzite), pre-treatment or sharper drill bits may be required.

II. How to Choose the Right Drill Bit and Drilling Technique?

To effectively drill granite, the following factors must be considered when selecting drill bits and drilling techniques:

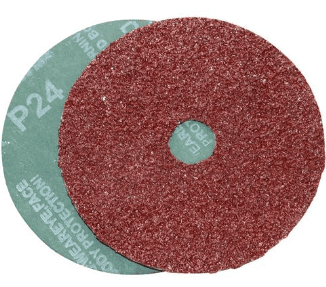

- Drill Bit Selection

The drill rod must have sufficient strength and hardness while being resistant to breakage and wear during drilling. Surface coatings such as hard alloy, multi-alloy, or polycrystalline diamond composites can improve bit quality and extend lifespan. - Drilling Mud

During drilling, mud circulation should be enhanced by increasing mud pressure and pump volume to effectively control side leakage and reduce wear on the bit and drill rod. The discharge volume and pressure of the mud pump should be selected based on hole depth and bit diameter. - Drilling Performance

Artificially controlling factors such as hole inclination and direction can improve drilling efficiency, shorten drilling time, and facilitate progress control. - Grouting

In engineering, grouting is essential for maintaining the sealing of the borehole wall and increasing aquifer thickness. Proper grouting techniques can significantly enhance granite drilling efficiency and hole quality.

How to Handle Hard Rock in Bored Pile Construction

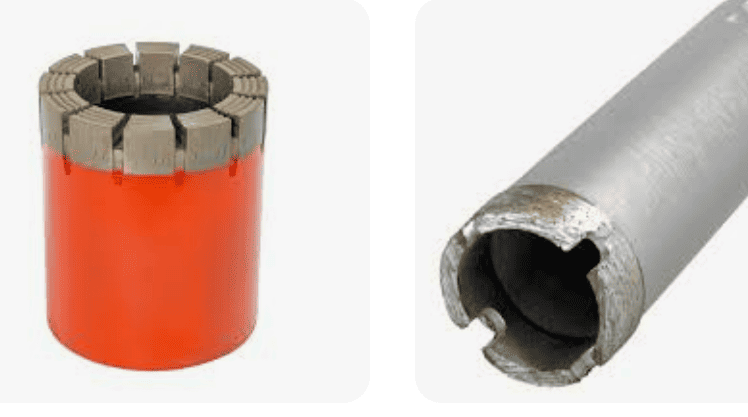

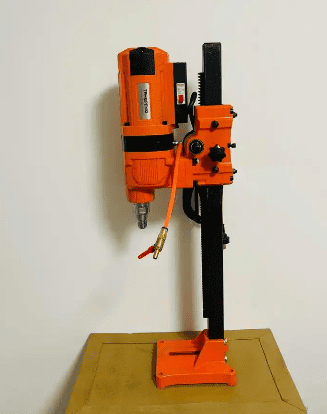

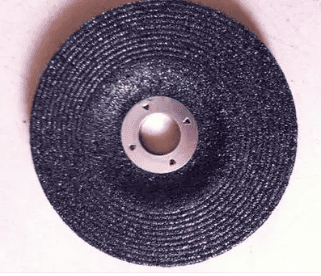

I. Hollow Drilling

Bored piles are typically constructed using drilling machines. When encountering hard rock, hollow drilling can be employed. The specific method involves using a hollow drill bit to perform gear cutting or rotary crushing on the rock under appropriate hole diameter conditions. The crushed debris is then removed to allow continued construction and pile penetration once the required hole depth and diameter are achieved.

II. Perforation

If hollow drilling is insufficient, perforation methods can be considered. This involves using high-speed rotary impact hammers to drive drill rods or bits into the rock for fragmentation. Hollow drilling is then used to clear the debris before resuming drilling.

III. Rock Drilling

Rock drilling is another common method, primarily using high-speed rotating drill rods or tools to crush the rock while drilling. This method is generally suitable for loosely structured rocks and requires specialized drill bits.

Note: These methods require the drilling machine to have sufficient drilling depth and power. Additionally, safety measures must be prioritized during construction, and proper protective measures should be implemented.

Conclusion

In summary, hollow drill bits can drill granite, but their applicability is limited. Selecting the right drill bit and drilling technique is crucial to improving efficiency and hole quality. During drilling, attention should be paid to controlling side leakage, extending bit lifespan, and managing hole depth and drill rod pressure.

Click if you are interested in other topics: 30KW EV Charger for Sale, Filling and Capping Machine for sale; 3 sides sealing bag customization.