What are the three types of cutting tools?

Comprehensive Guide to Cutting Tools: Classification, Applications and Technological Developments

Introduction

Cutting tools represent one of humanity’s oldest technological innovations, evolving from primitive stone tools to today’s computer-controlled systems. This guide provides a thorough examination of cutting tool classifications, working principles, application scenarios, and selection criteria across industries.

Section 1: Manual Cutting Tools

Manual tools remain indispensable for precision work and small-scale operations.

1.1 Blade Tools

- Chef’s Knives:

- Western-style: 8-12″ all-purpose blades

- Japanese Santoku: Shorter blade for precise vegetable work

- Steel types: High-carbon vs stainless steel comparisons

- Specialty Cutters:

- Bone saws: 14TPI teeth configuration for clean cuts

- Bread knives: 10″ serrated blades with 2mm tooth spacing

- Paring knives: 3-4″ blades for intricate peeling

1.2 Hand Saws

- Woodworking Saws:

- Crosscut saws (12-15TPI)

- Rip saws (5-7TPI)

- Japanese pull-saw advantages

- Metal Cutting:

- Hacksaw frame types (adjustable vs fixed)

- Bi-metal blade technology

- Optimal cutting speeds (40-60 strokes/min)

1.3 Other Manual Tools

- Chisels:

- Bevel edge (25°-30°) for joinery

- Mortise chisels (thicker blades)

- Specialty Tools:

- Glass cutters: Tungsten carbide wheel design

- Pipe cutters: Wheel-and-clamp mechanisms

Section 2: Power Cutting Tools

Modern electric tools revolutionize material processing.

2.1 Woodworking Power Tools

- Circular Saws:

- Blade diameters: 6-1/2″ to 10-1/4″

- Kerf widths: Thin-kerf (1.8mm) vs standard (2.4mm)

- Cordless advancements (20V-60V systems)

- Jigsaws:

- Stroke lengths: 3/4″ to 1-1/4″

- Orbital action settings

- Blade shank types (T-shank vs U-shank)

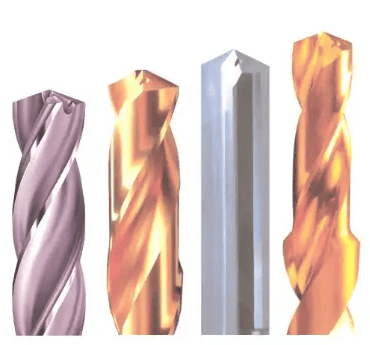

2.2 Metalworking Tools

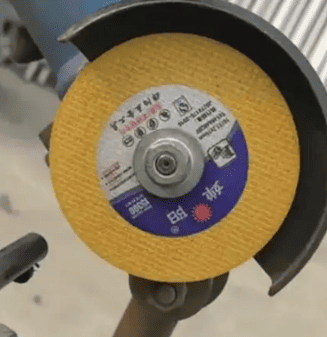

- Angle Grinders:

- Safety considerations (RPM ratings)

- Disc types: Type 1 vs Type 27

- 4-1/2″ vs 9″ tool comparisons

- Cold Saws:

- Tooth geometry for non-ferrous metals

- Cutting fluid requirements

2.3 Advanced Cutting Systems

- Plasma Cutters:

- Amperage requirements (30A-100A)

- CNC interface capabilities

- Hypertherm Duramax torch technology

Section 3: Industrial Cutting Equipment

Large-scale production demands specialized machinery.

3.1 Waterjet Technology

- Pump Systems:

- Direct drive vs intensifier pumps

- 60,000 PSI cutting capabilities

- Abrasive consumption rates (0.8-1.2lb/min)

- Cutting Head Innovations:

- 5-axis cutting heads

- Dynamic waterjet compensation

3.2 Laser Systems

- Fiber Lasers:

- 1μm wavelength advantages

- 6kW+ power for thick plate

- Cutting speed comparisons (m/min)

- CO2 Lasers:

- RF-excited vs glass tube

- Mirror maintenance requirements

3.3 CNC Machining Centers

- Tool Changers:

- 30+ tool capacity systems

- HSK vs CAT taper interfaces

- Automation Integration:

- Robotic part handling

- Lights-out manufacturing

Section 4: Special Application Tools Niche tools for specific industries.

4.1 Culinary Cutting Systems

- Commercial Meat Processing:

- Band saw specifications

- Cryogenic freezing integration

- Sushi Preparation:

- Yanagiba single-bevel geometry

- Steel hardness requirements (HRC 60+)

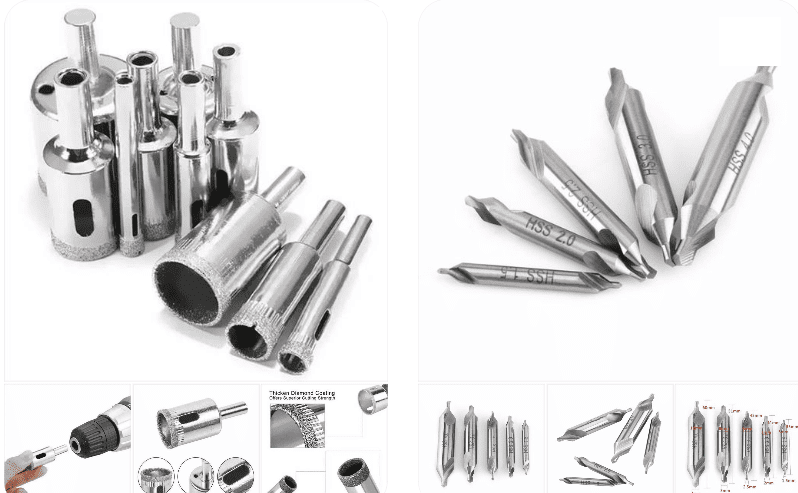

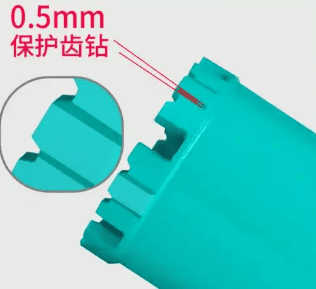

4.2 Construction Cutting

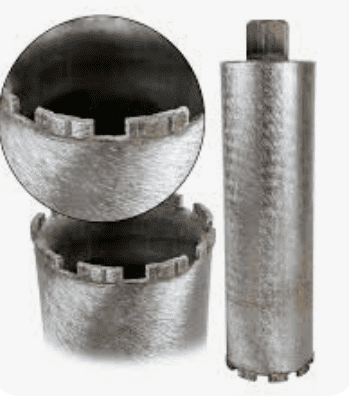

- Concrete Saws:

- Diesel vs electric power

- Diamond blade segment designs

- Rebar Cutters:

- Hydraulic vs mechanical

- 40mm capacity cutters

Section 5: Tool Selection Methodology

Detailed decision-making framework.

5.1 Material Considerations

- Metal Cutting:

- Ferrous vs non-ferrous requirements

- Heat-affected zone minimization

- Composite Materials:

- Delamination prevention

- Specialized tool coatings

5.2 Precision Requirements

- Tolerance Classes:

- ISO 2768 comparisons

- Surface finish considerations

5.3 Economic Factors

- Lifecycle Cost Analysis:

- Tooling cost per part

- Energy consumption metrics

Section 6: Safety and Maintenance

Comprehensive operational guidelines.

6.1 PPE Requirements

- Laser Safety:

- OD ratings for eyewear

- Class IV laser protocols

6.2 Maintenance Schedules

- Preventative Maintenance:

- Bearing lubrication intervals

- Linear guide inspection

Conclusion

Future trends including AI-optimized cutting paths and sustainable tool manufacturing.

Industrial News

Industrial Tech Knowledge

Industry Information:

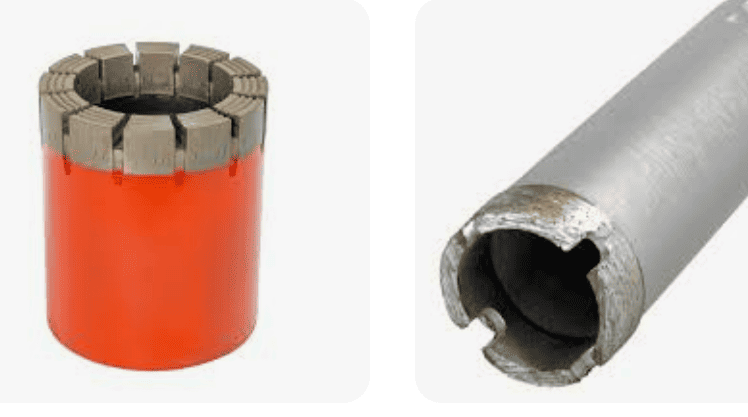

What size hole for core drilling?

The aperture range of core drills varies depending on their application: Industrial Sector Medical Equipment Sector For more precise parameters, it is recommended to consider the specific application scenario (e.g.,…

Can a core drill cut through rebar?

yes, a core drill can cut through rebar. 1. Can Hollow Drills Penetrate Rebar? Hollow drills are tools capable of drilling through concrete and rebar, but they cannot penetrate rebar…

Will a core drill go through metal?

Hollow drills can penetrate metal. A hollow drill is an industrial drilling tool that removes material through a multi-blade annular cutting structure, primarily used for machining metal materials. Its design…

How do l know if a drill bit is for concrete?

How to Identify Whether a Drill Bit is for Concrete or Wood 1. Bit Shape 2. Material 3. Performance Feedback Conclusion: Check shape, material, and drilling feel to avoid misuse…

What is the difference between a hole saw and a core drill?

What is the difference between a hole saw and a knockout punch? I. Definitions and Structures of Hole Saws and Knockout Punches A hole saw is a hollow drill bit…

How long does it take to core drill a hole?

Each drill bit can drill 1,000–3,000 holes. For example, drilling a 40mm diameter hole in 30mm thick steel plate takes only 25–40 seconds. When used with a magnetic drill, the…

Do SDS drill bits fit any drill?

Are Drill Bit Models Universal? Can All Types of Bits Be Used with Any Drill? Drill bits are not universally compatible—different bit models are designed for specific types of drills…

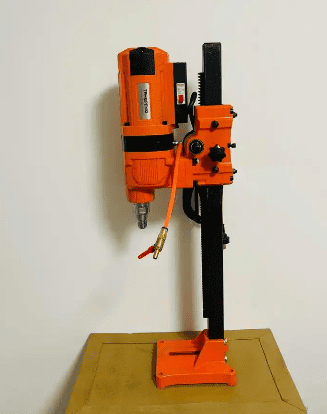

What is the difference between a hammer drill and a core drill?

The Difference Between Core Drills and Hammer Drills I. Principle and Applications of Core Drills A core drill is a hollow drilling tool with an inner drill bit that can…

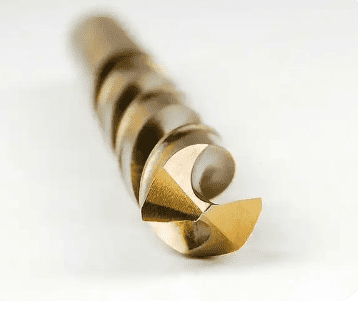

What is the difference between a twist drill and a core drill?

1. Structure Hollow drills and twist drills have different structures. A hollow drill has a hollowed-out center, leaving a sharp-edged bit, which generates more chips during drilling. A twist drill,…

How to attach core drill bit to drill?

How to Install a Core Drill Bit onto a Hand Drill In magnetic drill operations, the selection of drill bits is crucial. The core drill bit, as one of the…

Do you need a special drill for core drilling?

What kind of drill is a hollow drill bit paired with? Choose the right drill bit to improve work efficiency. Hollow drill bits need to be used with specialized drill…

What is a core drill bit used for?

Core Drill Bit A hollow drill bit is also known as a core drill bit, hole opener, center drill bit, steel plate drill bit, magnetic drill bit, rail drill bit,…

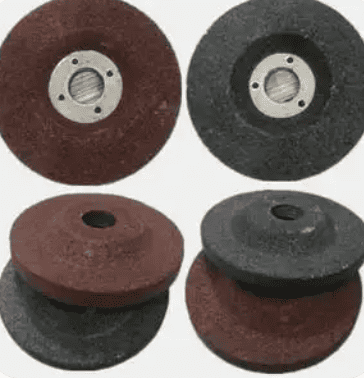

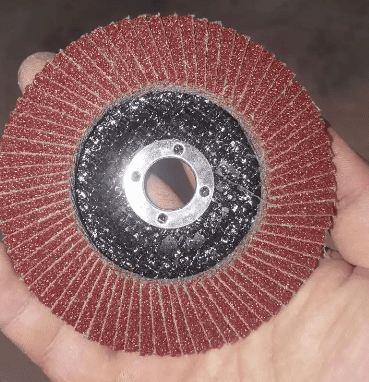

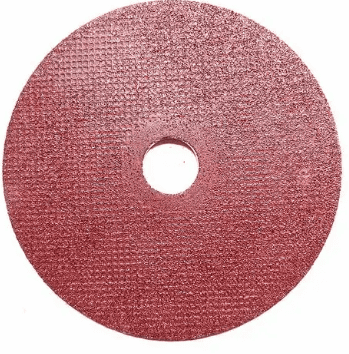

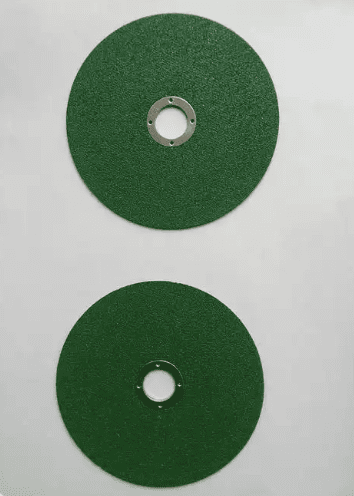

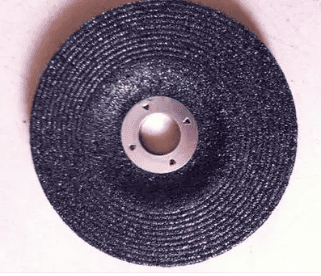

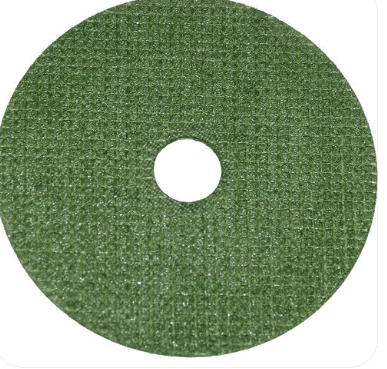

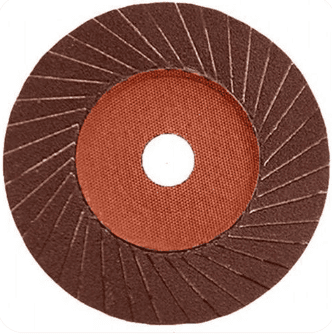

Which is better grinding wheels or flap discs for sharpening mower blades?

For grinding lawn mower blades, grinding wheel discs are better. Comparison of the Advantages and Disadvantages of Grinding Wheel Discs and Flap Discs Types and Applications of Grinding Wheel Discs…

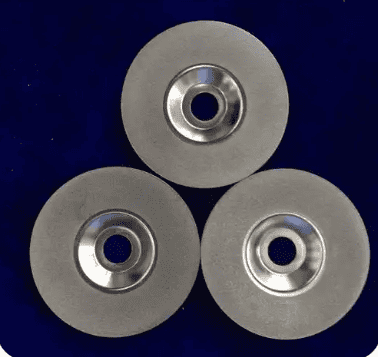

Which way should a grinding disc go?

Direction of Placing the Grinding Wheel: Which Side Should Face Up? I. Direction of Placing the Grinding Wheel Many people wonder which side of the grinding wheel should face up…

What is the best grinding disc for sharpening blades?

Resin Bond Diamond Grinding Wheel TestWheel Specification: 12A2/45°125×32×32×10×3 W20 100BGrinding Object: Sharpening PCD toolsGrinding Area: Two edges of PCD tool, edge width 4.6mm, PCD layer thickness 0.8mm, YG16 layer thickness…

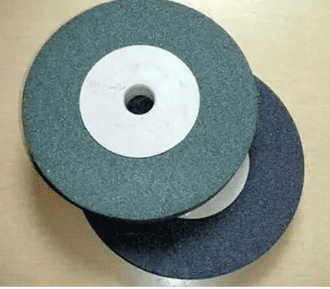

When should you stop using a grinding disc?

Is It Time to Replace Your Grinding Wheel? A Comprehensive Guide to Wheel Replacement and Dressing In the field of grinding, the condition of the grinding wheel plays a decisive…

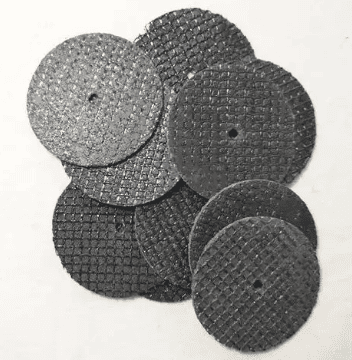

Can you use a cutting disc for grinding?

Can Cutting Discs Be Used for Grinding? Although cutting discs are primarily designed for cutting and grinding, they can also be used for polishing in many cases. 1. Uses and…

How do you test an abrasive wheel for cracks?

Identifying Cracks and Fractures in Grinding Wheels Before Use Before using a grinding wheel, it is essential to thoroughly inspect it for cracks or fractures to ensure safety. 1. Why…

What should be done before installing a grinding wheel?

Pre-Installation Preparations and Checks for Grinding Wheels Before installing a grinding wheel, the following preparations and inspections must be conducted: Installation Steps Grinder Operation Procedure 1. Preparations Before operation, ensure:…

How do you tell what grit a grinding wheel is?

Detailed Explanation of Abrasive Grit Size: A Comprehensive Analysis from Coarse to Fine Abrasive grit size, more accurately referred to as “particle size distribution,” is commonly denoted by terms like…

What type of grinding wheel do l need?

The Complete Guide to Grinding Wheel Selection: A Comprehensive Analysis from Structure to Abrasives Fundamentals of Grinding Wheels Understanding the basic principles of grinding wheels is key to selecting the…

Which type of grinding wheel is best for hard materials?

own aluminum oxide has high hardness and toughness, making it suitable for grinding metals with high tensile strength, such as carbon steel, alloy steel, malleable cast iron, and hard bronze…

Where is the best place to stand when using a grinder?

When using a grinding wheel machine, the operator must wear a safety helmet, protective goggles, and gloves, and should not face the grinding wheel directly but stand to the side…

Will a grinder cut through wood?

Can Angle Grinders Cut Wood? Safety & Usage Guide Key Takeaways I. Risks of Cutting Wood with an Angle Grinder II. If You Must Use an Angle Grinder for Wood…

How do you use a grinder with a cutting wheel?

Angle Grinder Cutting Disc Usage Guide: Methods & Safety Precautions I. Proper Usage of Cutting Discs with Angle Grinders II. Critical Safety Measures III. Step-by-Step Installation Guide Pro Tip: Always…

What is the difference between SDs and Hss drill bits?

Drill Bit Model Numbers: A Comprehensive Guide Drill bit model numbers consist of letters and numbers that indicate critical specifications including diameter, shank size, flute length, and material composition. Understanding…

Can you put a cut off wheel on an angle grinder?

Can Angle Grinders Cut Materials? Can They Use Cutting Discs? 1. Why Angle Grinders Are Not Ideal for Cutting Angle grinders are primarily designed for grinding and polishing, not cutting…

What is the difference between a grinder and a cutting wheel?

What’s the Difference Between Grinding Wheels and Cutting Discs? 1. Definitions and Applications 2. Structure and Materials Feature Grinding Wheel Cutting Disc Abrasives Aluminum oxide, silicon carbide, boron carbide Silicon…

Is it safe to grind with a cutting wheel?

Safe to Use a Cutting Disc for Grinding?No, It Is Not Safe. Why Cutting Discs Should Never Be Used for Grinding Using cutting discs (on angle grinders or cut-off tools)…

What material can a grinder not cut?

Materials That Should NOT Be Cut with Grinding Wheels Grinding wheels are designed for hard, non-combustible materials like metals and stone. However, certain materials pose safety risks or can damage…

Can you use a cutting wheel on a bench grinder?

While physically possible, using cutting discs on bench grinders significantly increases accident risks. Can Bench Grinders Use Cutting Discs? Safety & Usage Guide Key Considerations: If Absolutely Necessary:✔ Disc Selection:…

Do l need a SDS drill for brick?

Yes, SDS drill bits are suitable for drilling into bricks.SDS drill bits, especially impact drill bits such as SDS drill bits or hammer drill bits, combine rotation and hammering action to penetrate hard cementitious materials,…

How much torque does a SDs drill have?

How much torque does a SDs drill have? 90 Newton Meters normally.The torque of an SDS drill bit is typically 90 Newton meters. An SDS drill bit is a specialized tool designed for…

Can you use an SDS drill as a screwdriver?

SDS drill bits cannot be used as screwdrivers. SDS drill bits are designed for drilling, and their structure and material composition make them unsuitable for driving screws, which may lead to…

What is the difference between a hammer drill and SDS drill?

Key Differences Between Rotary Hammers and SDS Drills The primary distinctions between rotary hammers and SDS drills lie in their design principles, applications, and chuck systems. 1. Design Principles and…

What does SDS mean on a rotary drill?

DS mean on a rotary drill? The official term for hammer drill bits is “rotary impact drill bits”, also known as “SDS drill bits”. SDS stands for “Steck-Dreh-System” (Insert-Twist-Secure system),…

What is a SDS drill used for?

SDS drill bits are primarily used for drilling into hard construction materials such as concrete and brick, offering high efficiency and durability. SDS drill bits are specially designed for drilling…

Do all SDs drills have a clutch?

Not all SDS drill bits come with a chuck. SDS drill bits are generally divided into two types: SDS-plus and SDS-max, both of which require compatible chucks for proper use…

Are there SDS drill bits for metal?

SDS Drill Bits Suitable for Metal Do Exist For example, Bosch’s GSB120 Dual-Power Impact Drill is a high-performance household tool suitable for various daily repair and assembly tasks. Equipped with…

Which cutting wheels would cut the fastest?

Optimal Grinding Wheels for Faster Metal Grinding with Angle Grinders 1. Best Grinding Wheels for Fast Metal Removal For high-speed metal grinding, the top choices are: Wheel Type Best For…

Can a grinder cut through bolts?

Can an Angle Grinder Cut Bolts? Safety & Techniques 1. Can an Angle Grinder Cut Bolts? ✅ Yes, angle grinders can cut bolts, but with strict safety precautions. Best for:…

What size is a standard cutting wheel?

What are the specifications and models of cutting discs? How to maintain a cutting machine? Cutting discs belong to the category of grinding wheels. They are thin sheets made of…

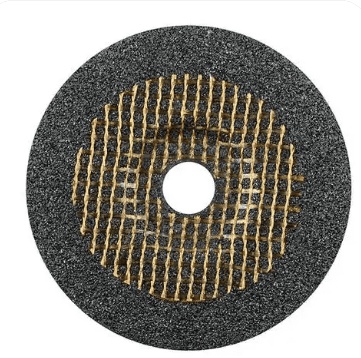

Introduction of cutting wheel

Cutting Wheels: Classification and Applications Cutting wheels belong to the abrasive wheel category, consisting of abrasive grains and resin bonds to form thin discs for cutting ordinary steel, stainless steel,…

What type of cutting wheel for metal?

Types of Metal Cutting Discs Metal cutting discs are made from different materials, each with its own applicable scope and cutting performance. Common types of metal cutting discs include: How…

What tool uses a cutting wheel?

Detailed Translation and Extension: Tools Utilizing Cutting Blades The primary tools that employ cutting blades include angle grinders, electric drills, and cutting machines. Types of Cutting Blades and Their Applications…

What are the three types of cutting tools?

Comprehensive Guide to Cutting Tools: Classification, Applications and Technological Developments Introduction Cutting tools represent one of humanity’s oldest technological innovations, evolving from primitive stone tools to today’s computer-controlled systems. This…