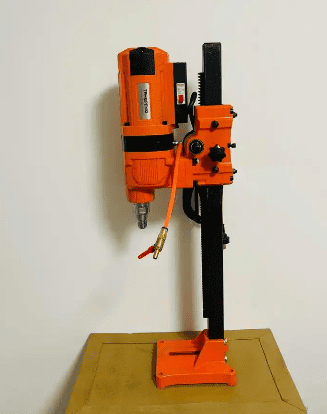

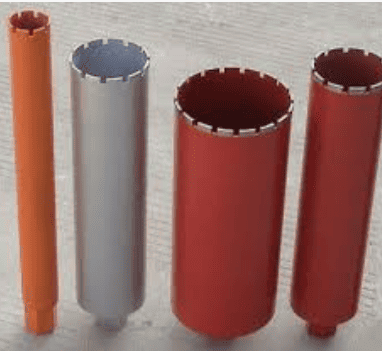

Can you core drill without water?

No. Water serves to cool and reduce friction. Operating without water can easily burn out the motor. While a water drill can bore holes without water, it is not good for the drill or the bit and should not be done frequently.

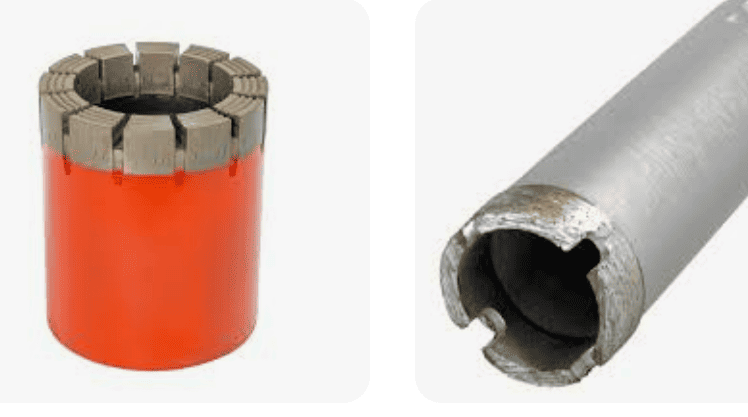

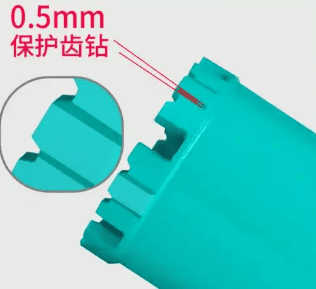

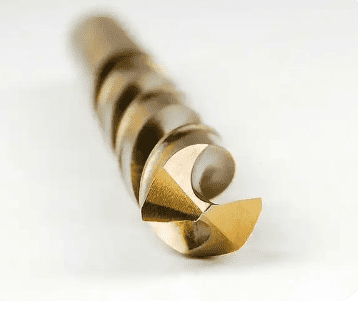

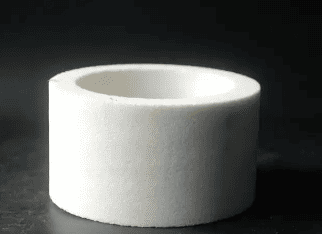

A water drill, as the name suggests, is a drill that uses water. During drilling, water lubricates the bit and the wall, lowers the bit’s temperature, and aids the cutting action of the alloy bit. Only in very rare cases (such as when moisture must be avoided) is it operated without water. In such cases, both the motor and the bit will suffer damage, with the bit being particularly severely affected, leading to a reduced lifespan. Sometimes, to minimize water-induced contamination or damage, a small amount of water is added to the hollow bit, and a cloth is used to plug the hole before drilling.

When using a water drill, adding water is necessary for cooling and lubrication. Operating without proper cooling and lubrication can cause the following issues:

- Damage to the Wall Surface

Drilling without water can overheat the bit, potentially damaging the wall material, causing cracks or breakage. It may also melt certain materials inside the wall, compromising its structural integrity and weakening the wall’s overall strength and stability. - Reduced Tool Lifespan or Severe Damage

Prolonged high temperatures from operating without water can cause the bit to overheat, leading to deformation or brittleness, shortening its lifespan. In severe cases, the bit may get stuck in the wall, making removal difficult and causing physical damage to the drill itself.

Additionally, high temperatures reduce the bit’s precision and efficiency, and in worse scenarios, may lead to issues like clogging or other unexpected problems. - Decreased Work Efficiency

Without proper water cooling and lubrication, the difficulty of operation increases significantly, prolonging the time required to complete the task and reducing work quality. This negatively impacts overall efficiency and results. Therefore, it is essential to follow proper procedures to ensure safety, reliability, and high efficiency.

How to Use a Water Drill Without Tap Water

Using a water drill without tap water requires precise control.

- Stable Grip

Hold the drill firmly against your chest to prevent deviation due to hand instability. - Proper Angle

Tilt the drill bit at about 50 degrees to the wall initially, ensuring only partial contact to avoid slippage. Once the bit starts penetrating, gradually adjust it to a vertical position until fully secured. - Steady Operation

Maintain stability during drilling, avoiding frequent movements that could damage the bit or motor. - Controlled Water Usage

A moderate amount of water is necessary—neither too much nor too little. Proper water flow cools the bit, reduces wear, and helps remove debris for a clean bore. - Gradual Adjustment

Adjust the angle incrementally, avoiding abrupt changes. Overheating from excessive friction can damage the bit. - Patience and Precision

Avoid unnecessary movements to maintain accuracy. After drilling, promptly remove the bit to clear debris and prevent buildup.

By following these techniques, even without tap water, you can successfully complete drilling tasks with a water drill.